Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Re-boiler is ahigh-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid. Re-boiler is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

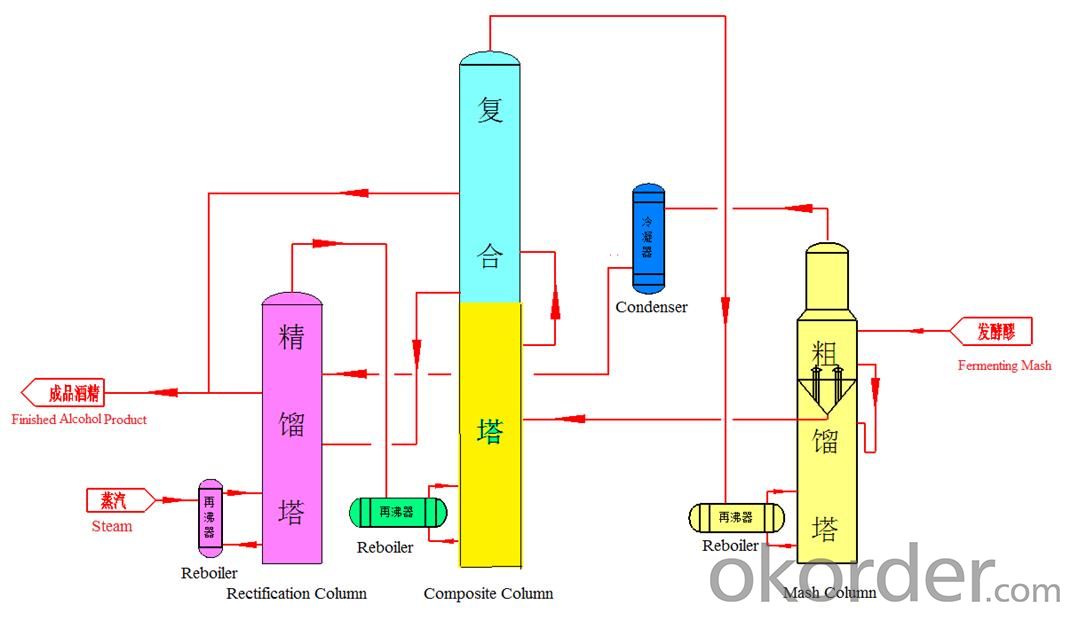

Double-Mash-Column Three-Effect DistillationProcess

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

Weown advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:10yrs parts/ 10yrs compressor/ 10yrs coil/ 1yr labor or spend $1600 more for a unit with10yrs parts/ 10yrs labor/ 15yrs coil

- I'd go with the lower end and then your utility company should have a plan you can purchase and pay with your bill monthly. They are not very expensive and can be for full replacement. That $2400 banked and getting interest could pay for many months of appliance insurance. Check with you utility for the details.

- Q:How to culcalate heat exchange?

- Simply for liquids Q(heat)=m(mass). c(coeff). Delta t(change in temperature) For gases Q=m(mass). Le,b(melting or evaporation coefficient)

- Q:Hi everybody I need some help over here. my Kenmore dryer in not drying property. I call for a guy and he said would be the heater element.I have try open the back of the dryer however I didn't figure out which way go.Would someone help me with directions to to Replace my quot;gasquot; Dryer's Heating Element ?Also, I got some answer so far but I got confuse. If my dryer have or not Heating Element or the problem could be somewhere by the pilot.Thanks.Answer so far:Snipper said: quot;It's removed from the front,turn off the gas!!!quot;whatwho said quot;yes newer dryers use a heating element to ignite start the flame. older models have a pilot lite.quot;

- check the limit switch they burn out if the dryer vent becomes clogged. most dryers have automatic reset in the heat exchanger, and a actual fusible link limit that will burn out in the exhaust. they dont look like a fuse looks like a little white piece of plastic with a 1/4 screw in it on kenmores

- Q:Hello to everyone,I have a question to ask.I have currently beenrenting a 3 bedroom home since 2002 that has central andmy gas bills are reallly high during the winter.On average itruns a little over $300 per/month.It is a very old unit.I have seenfriends and family gas bill during winter who have space heatersno central unit and their gas bill is significantly lower.The landlordsays I can install space heaters since lines are alreadyin place in each individual room.what I would like to knowis will my gas bill be noticably low using 10,000 btu space heatersto heat the home? I was told that central heat/air is the mostexpensive gas heat and that by electing to use space heatersI will see a drop in my utility bill. does anyone know or can estimatewhat my bill will be reduced to from $340-380 collectively?

- in case you stay someplace you are able to actual exist without warmth, then it received't take a lot to deliver the temperature as a lot as a real looking aspect. verify your electric powered bill to confirm what your software costs in line with kilowatt hour (kwh). In maximum parts of the rustic it really isn't any more effective than 15 cents or a lot less. One fan-forced, 1500 watt heater will genuinely advance your mattress room temperature from 40 F to 70 F -- or your residing room. in case your fee of electrical energy is 0.15, the heater would fee 0.22 in line with hour to operate if it runs finished time. in spite of the indisputable fact that the warmers have a thermostat so maximum in all chance it might run in basic terms seventy 5% of the time. At those estimates, it might fee $121.00 in line with month to run the heater 24 hours in line with day. obviously your software would in basic terms be charging 0.12; it varies around the rustic. verify it out. a good, fan-forced 1500 watt ceramic heater might want to be bought new for round $50.00.

- Q:i only want to know that what is a good absorber of heat i only need its aplication?

- silver, gold, copper... In general,metals are very good heat absorbers. In ambient-air heat absorbers composed of many heat exchanger elements arranged one above another, the flowing air often flows too smoothly through the intermediate spaces, so that the heat exchange takes place only incompletely. As a result of the insertion of lattice grids onto the (smooth) surface of the heat exchanger elements, this uniform flow is varied. The result of this is a greater absorption of heat by the absorber.

- Q:Thaks.

- The designing of any heat exchanger is a very complex undertaking involving both science and art; therefore, anyone who has taken the trouble to develop software to incorporate the necessary math and experience is not going to give that effort away for free. Any free software that you might acquire for designing heat exchangers will not be worth the CD it comes on.

- Q:1970 beetle..what do the two levers do next to the handbrake? are they both for the heat exchangers?

- Yes they operate the right and left heat exchangers, pull for heat!

- Q:by how much will the coolant (50/50 fresh water/antifreeze) temperature increase when it is already 180F flowing into the manifold thru a 1/2quot; ID hose? the coolant will flow out of the back of the block thru 1/2quot; NPT fittings, into the base of the manifolds, then out of the top (dry joint) and into 2 (each manifold has it's own, 1 traditionally used for bypass, the other for the heater core in an automotive application) 1/2quot; auxillary coolant-intake ports on the waterpump. when the water reaches 180F, the thermostat will open flushing the block water to the heat exchanger, but the manifold coolant will always come out of the block and return directly to the pump. my concern is; will i over-heat the coolant? i figure this could be an elegant way of keeping the block at 180 and prevent cold shock as the heated water from the manifolds would mix with the cooled water coming from the exchanger. also, is 1/2quot; ID hose too small? assume an aftermarket water pump.thanks!

- at one time merc cruiser sold aluminum manifolds. Check with them and see if they are still listed.

- Q:My double door fridge gets warm in the fridge section at times.

- no its a sign of low coolant, if its less than 3 yrs old contact the manufacture,

- Q:I'm guessing there's something I haven't checked. I've replaced the air filters and vents but everymorning I wake up when the heatings been on that night I have a sore throat and stuffed up nose. Any HVAC geniuses out there? Thanks.

- Sounds like you need a humidifier,also an electronic air cleaner.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords