Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

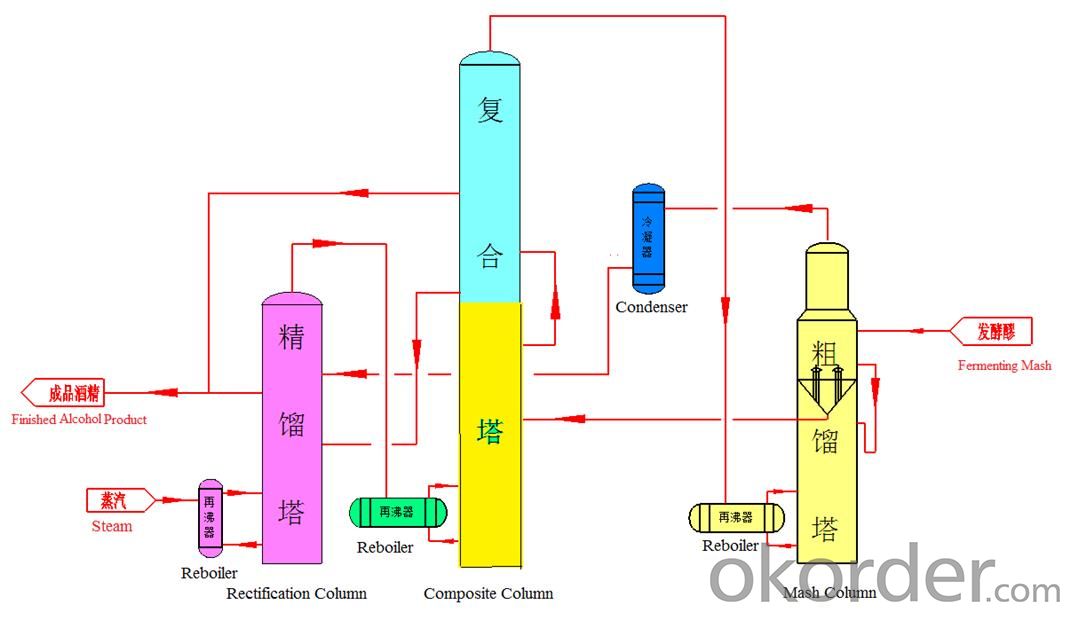

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: This gadget goes on the car window and as the heat increases, the gadget starts exhausting the hot air keeping the car cool. I am not sure how it works but I saw it on TV infomercial about a month ago. Several google searches have not paid off. Please respond if you know of it or anything like it. Texas is HOT and I have a black car.

- Saw it on TV yesterday. Solar powered, These commercial spots often air for a time during the same program at approximately the same time evrey day. Didn't catch the name though. If I see it tonight I'll undate my answer...........

- Q: How do you say "The Exchanger" in Spanish, French, and Italian?

- italian: male - lo scambiatore (lo scambeeahtoreh) female - la scambiatrice (lah scambeeahtreecheh)

- Q: It has been really cold for the last few days and heat is working but is not reaching desired temperature. It shuts off and then starts again. Reaches about 6 degrees below desired temperature and once shut off, the temperature drops significantly and then it starts working again. The furnace seems to work fine when it is on but need to understand why it doesn't reach desired temperature.

- Would expect you need a new furnace since you also are having cycling problems. Check the plenium temps and the air temps just out of the registers.

- Q: A heat exchanger (boiler) produces dry steam at 100 degrees C from feed water at 30 degrees C at a rate of 1.5kg/s. The specific heat capacity of water is 4187J/Kg and its specific latent heat of vapourisation is 2,257,000 J/kg- The heat exchanger receives heat energy at a rate of 4MW from the fuel used. Determine the thermal eficency from the boiler.Formulas or guidance would be appreciated thankyou.

- the water must be raised 70 degrees C (1.5 kg/s)(4,187 J/kg C)(70 C) = 439,635 Joules per second = 0.440 Megawatts add to that the heat of vaporisation (1.5 kg/s)(2,257,000 J/kg)= 3,385,500 Joules per second = 3.386 Megawatts Total power required 3.825 Megawatt efficiency = 3.825/4.00 = 95.63%

- Q: I have been given a question to do (given below.) I don't neccersarily want the question working out but a method (equations to apply and in what order) would be very much appreciated!A double pipe heat exchanger is made up from a length of 25mm i.d. steel pipe of 2.5mm thickness, and a length of 75mm i.d. pipe. The fluid in both pipes is water. Estimate the heat transfer coefficients at the outside and inside of the inner pipe for the following conditions.Outer pipe flow-rate 5kg/s @ 23? CInner pipe flow-rate 0.5kg/s @ 51?CUse the correlation for turbulent flowNu = 0.023 Re0.8 Pr0.33 (μ/μw)0.14The physical properties of water are: Cp of water @ 23?C = 4.187kJ/kgKCp of water @ 51?C = 4.184kJ/kgKk of water @ 23?C = 0.670W/mKk of water @ 51?C = 0.635W/mKI have also been given the density and viscosity of water at varying temperatures.

- Individual Heat Transfer Coefficient

- Q: For an outdoor pool, Is a swimming pool heat pump suitable in the uk for all year round swimming in terms of temperature and cost to run? I understand efficiency drops in colder weather.Thanks

- For an air to water heat pump, no, not really as a stand alone unit. Yes, if you add a gas fired heater as a back up for days that the outside air gets below 0C and you're sensible in keeping a solar blanket on the pool to minimize heat loss. As a general rule, when the air temp gets to -10 C, these units won't give you any heat at all or at least not enough to offset your pool's heat loss. If it's a geo thermal heat pump, your ability to scam heat gets better because you have a warmer source, but your costs also go up as their pretty expensive to buy and install. I've only ever seen this type in conjunction with household heating that has had the extra heat exchanger installed for the pool heat.

- Q: I'm trying to get started on this problem but it looks like I don't have enough information to start it. I'll rewrite it:High pressure 20 degree Celsius water (no boiling) flows at 2 kg/s in a smooth 12 mm diameter pipe with pressurized super heated steam condensing on the outside in a heat exchanger. The steam maintains the pipe wall temperature at 140 degrees Celsius and the water flow is fully developed before entering the heat exchanger section that is 10 meters long. Determine Nu, h, exit temperature and total heat rate q in the heat exchanger. Assume water properties to be k = .613 W/m*K, cp = 4.179 kj/kg*K, u = 855x10^-6 kg/m*s, and Pr = 5.83.The water properties don't lead to any one temperature, and obviously determining T exit is essential in getting the rest of the information. I'm just unsure where exactly to start. I don't even have a value for density so I can't get velocity. Any hints would be appreciated.

- If you prefer the hard way, look up heat exchanger in your text. This is a simple case, since the temp outside is fixed. You can set up the integral and integrate to get the temp. Or, should be able to use same inlet and outlet temp to use standard heat exchanger calcs derived in your text. It all gets back to the log mean temperature difference. Good luck!

- Q: in hot area like the middle east we plan to build a cast house to solidify the molten aluminium and cast into ingots ... i would like to know the best technology to cool the process water cooling towers or heat exchanger??

- I worked for DUBALl In Dubai UAE a number of years ago building a new casthouse and increasing the size of their cooling tower system Heat exchangers would have to be very large due to the amount of water need to cool the systems and due to the ambient temperature in Dubai during the summer months we only go about 5-10Centigrade DeltaT so we had to have a very large reservoir of water and additional cooling towers installed by Marley Cooling Tower Specialists. You need to know what temperature the hydraulic systems run at under normal conditions i.e. what they have been desinged to operate under and then add the Dubai factor increasing the operating temperature by a factor equal t the difference between the equipment built in Germany or Austria. Gautchi and Mekatherm and Hertwich supplied the euipment for theplant If you need any more you can email me

- Q: if main steam header pressure is 160psi.Will Pressure regulation at inlet of heat exchanger help to descipate more heat?

- If your steam is 100% pure steam, I can't see how dropping the pressure would help, in fact you loose some energy due to entropy loss by going through the pressure regulator. However, if your main steam is less than 100% pure, a steam/water mix, it might help. If you drop the pressure, at least some of the water would flash to steam and condensing steam has a much higher heat transfer coefficient than flowing water. This may increase the amount of heat transfer in the exchanger.

- Q: Please tell me about both parallel flow and counter flow .

- Concentric tube heat exchangers are the simplest type of heat exchanger. Essentially its a tube inside of a tube (or outer jacket if you like). In one part a hot fluid flows and transfers its heat through the wall of a metal (usually copper/stainless steel) to another cold fluid. Parallel flow and counter flow refer to the fluid flow directions relative to each other. If both inlets are on the same side and flow in the same direction then this is known as parallel flow. The opposite is known as counter flow. Both flows are used common but the most common configuration is counter flow as it allows the most temperature differental possible as you are presumably heating or cooling a liquid. You would use parallel flow if you want to generate a common temperature between the two fluids.

Send your message to us

Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords