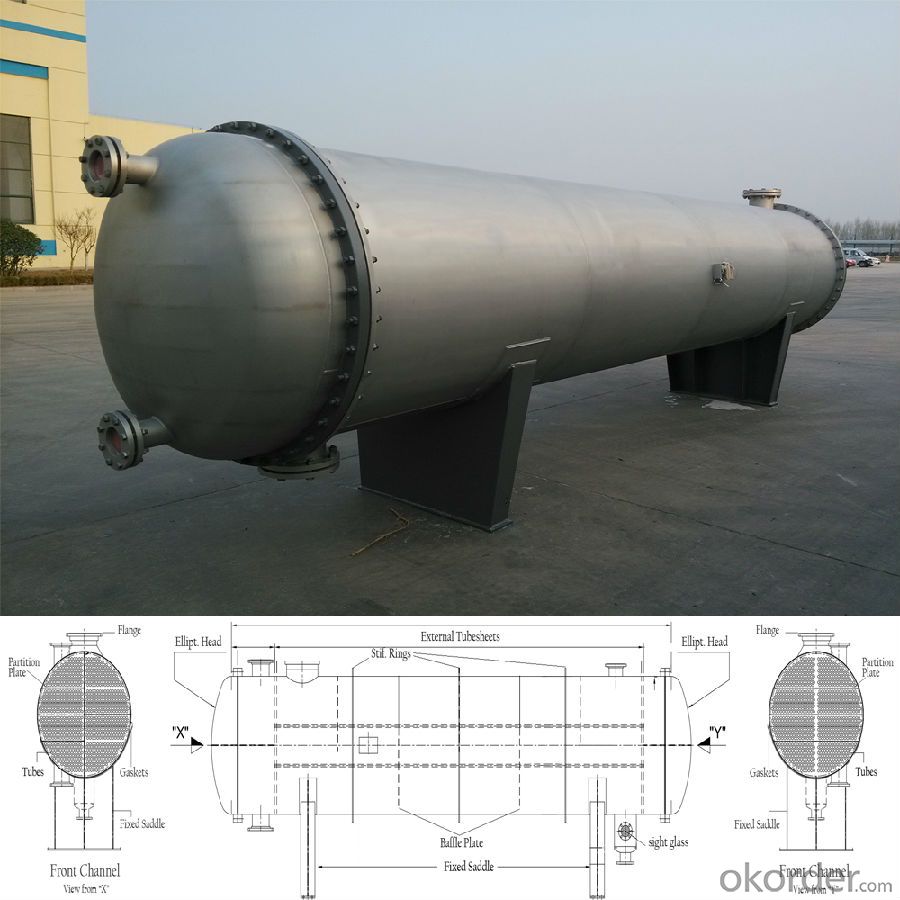

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-heater is a high-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid.

The heatexchangeris divided into tubular heat exchanger, spiral plate heat exchanger.And the tubular heat exchanger comprises condenser, Pre-heater, Re-boiler,Evaporator, drying machine. The spiral plate heat exchanger comprisesnon-dismountable and dismountable exchanger.

The heatexchanger is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latest Five-Column Three-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

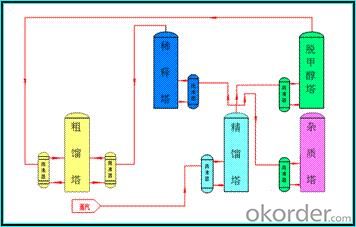

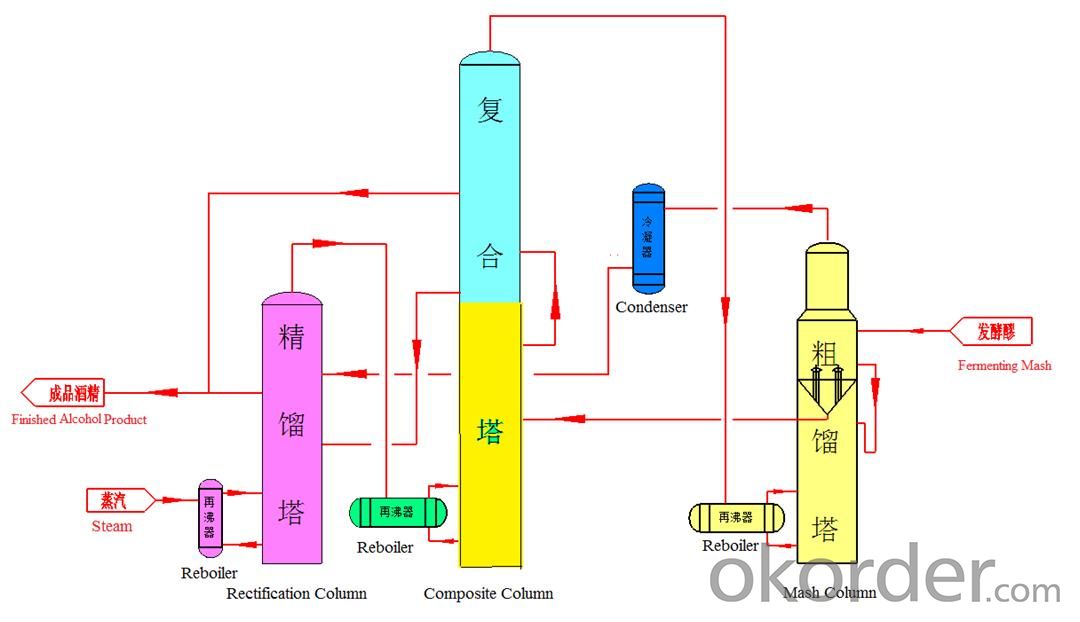

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2).We can reach the project site after receiving the user’s notification.

6.Package & Transport

- Q: important uses of shehh and tube heat exchanger in industry and manifacturing

- They are used in many industries where it is necessary to heat or cool a fluid stream or to simply save the heat that might otherwise be lost. Some examples are: 1. condensers for steam in a power plant. 2. heaters for boiler feed water in a power plant 3. condensers and reboilers in fractionation systems in refineries and petrochemical plants. 4. chillers and heaters in HVAC systems in buildings

- Q: We just knocked a wall out of our house and a heat duct was exposed and my dog was walking by and dropped the ball and it dropped in the duct and rolled down i'm guessing towards the heater. Is that a fire hazard?

- Duct Down

- Q: I'm getting quotes for a replacement for our hot water heater. So far I've gotten 22K for materials and installation of a solar hot water heater (3-4 collector panels) with heat rejection and single zone open direct radiant heating to one floor (accessible through drop ceiling underneath). Both quotes include a backup hot water heating system; the expensive one would involve installing a new backup high efficiency heater by converting our propane tank to use for heating. This would be either the Polaris or 2 Takagi Jrs, one for the solar hot water and another to power the radiant heat. Another quote is for 12K for only the solar hot water and heat rejection using the Velux system.Are these really high? I've already contacted 3 companies but it doesn't look like too many people are installing them in Maryland yet. I'm still waiting on a quote from one final company. Thanks!

- You should ask a trusted person in a sales business :)

- Q: Once started, the nuclear reaction generates copious amounts of heat. Too much heat could lead to several problems, so what are used to limit the amount of heat generated?Would it be the control rods, or the cooling towers?

- It would be the control rods and the moderators. These are dummy rods that are put in place of the nuclear fuel rods, in order to decrease the amount of heat production in the reactor core, from what it otherwise would be if all rods were active uranium reactors. These rods also serve the purpose of absorbing stray neutrons to prevent the chain fission reactions from growing out of control. The cooling tower is actually the least nuclear and the least power-planet-like of a nuclear power plant. That is to say, there are no nuclear reactions going on inside of it, and it isn't one of the devices of the Rankine cycle that converts the heat into work. There are at least two degrees of separation between the fluids in the reactor core and the fluids in the cooling tower. Rather, it is a device to provide a sink of heat to the condenser of the Rankine cycle. What the cooling tower is, is the method to reject heat to the background by replacing a water stream with an airstream and a much lower feedwater flowrate. The alternative to a cooling tower is a high flow rate of natural water.

- Q: Many air conditioners give more heating/cooling power than they consume. How did they do that? I know this is equivalent power but still it is way more than consumed.

- It doesn't make heat, it moves heat, it's a heat pump, the 0.7 kw only moves heat.

- Q: Who can tell me the anti forst and impact resistance capability of heat exchanger brass tube?

- ascent brass tube you can buy from China all have perfect thermal conductivity, the H85 tube in the heat exchanger can ensure a rather long service life of the exchanger for the outstanding hardness, so heat exchanger brass tube will have great anti forst and impact sesistance capbility.

- Q: I am being told by a furnace repair guy (who I had come in to perform annual maintenance) that I have cracks in the heat exchanger and that he needs to turn off my gas right now (by law). He ended up leaving without turning off the gas, but only after I signed stating that he will order this heat exchanger part and when it is in (in the next day or two) he will install it. I just don't know if he is honest or not. It is going to run me about $700. As an unemployed single mom, that is a LOT of money! I also don't want to take any chances with this quot;silent killerquot; with my kids in the house.

- Cracked Heat Exchanger

- Q: quot;quot;quot;Gorrie’s process took advantage of the difference between temperature and heat. You can compress a gas without adding heat, but you will be raising its temperature by bottling up its molecules in a smaller space. Similarly, if you let a gas expand, its temperature will drop, even if you have not removed any heat. So if you compress a gas, draw off part of its heat, and then let it expand, it will be colder than it was to begin with. This is the basic idea behind refrigeration.quot;quot;I pretty sure, each time you compress a gas its temperature increase also its pressure. It mention on this article, you can compress a gas without adding heat. that not right!!!

- According to thermodynamics it is impossible practically, but but Perpetual Motion machine which is a pure theoretically concept, can press the air so slow that it does not generate heat.

- Q: it is a worcester combination boiler and it seems to be an intermittent fault.

- Have you checked the pressure on the boiler is between 1 2 bar. If it is then you will have a problem with either the plate to plate heat exchanger, a faulty thermistor or the diverter valve is passing. Have a look on corgi`s website for an engineer near you

- Q: I have an old Lenox G12 natural gas furnace that is not producing any heat. I've turned off the pilot and relit it again with a nice flame. When the fan comes on the flame diminishes somewhat but stays on. However the burner tubes are not lighting up and there is no heat. P.S. There was a slight gas odor when we got home from work.

- THE FURNACE NEEDS CLEANING.YOU HAVE DIRT,RUST FLAKES THAT ARE PROHIBITING THE TUBES TO KICK IN

Send your message to us

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords