Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. The spiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

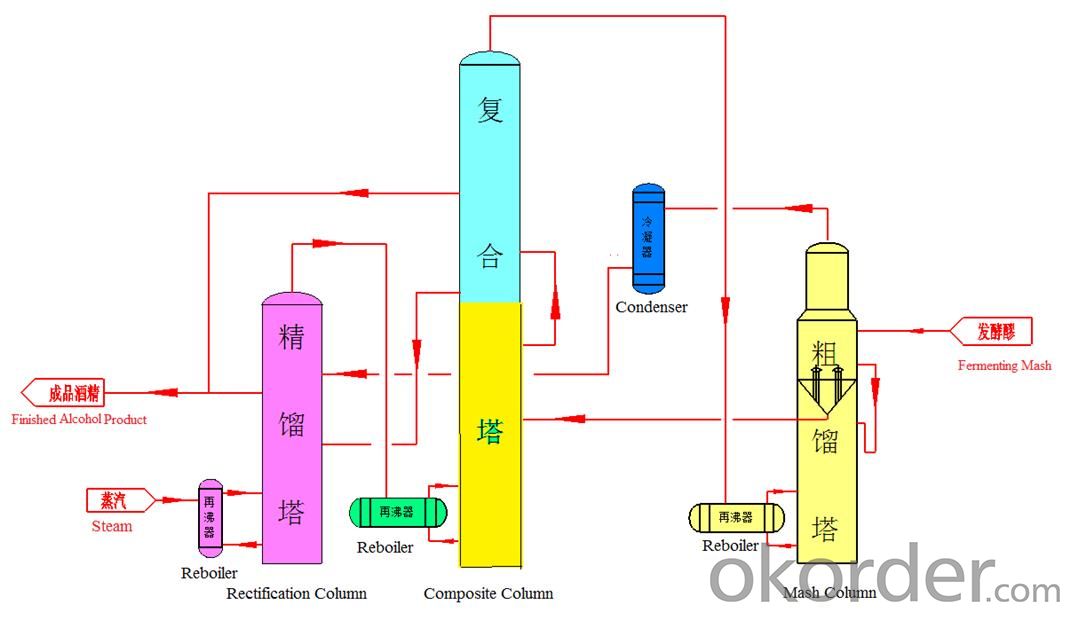

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: with the aid of a diagram, discuss in detail the operational of a heat exchanger.?

- the warmth exchanger could be under guarantee from the manufacture, even nonetheless this could opt to be confirm with the close by grant living house alongside with your kind and serial huge form off the furnace. i could additionally, question the warmth exchanger crack, as some furnace have whats called a front plate. the front plate over the years will crack. this could nicely be a replaceable section. And is often misdiagnosed as a cracked warmth exchanger. seven-hundred is honest for the value. i could get a carbon monoxide detector and setting up that. you ought to tell the guy to hold off and have somebody else seem at it. some companies available supply a unfastened 2d opinion. you ought to call them and say that the 1st employer says (your fibbing here) which you have 2 options here replace the entire furnace or fix / replaced the warmth exchanger. And which you elect them (the 2d employer) to envision this and provide you a 2d quote. Its enormously uncommon for the warmth exchanger to crack in a residential living house. Its is achieveable yet returned returned to my assertion above appropriate to the front plate. only attempting to supply you another issues to look at and ask.

- Q: hot starch solution is being cooled from about 60 deg C to 30 deg C..... but possible channeling occuring... leading to the temperature on the outlet starch pipe not being uniform.not sure on how to conduct the energy balance using a plate heat exchanger... please add units and equations in solution that it can be followed.

- What do you mean by the outlet temperature not being uniform. Do you mean not the same over time? Or are there multiple outlets and the temperature from each outlet is not the same? If the inlet and outlet channels or headers are not designed carefully to allow for good fluid dynamics then there can certainly be portions of the exchanger that is not getting the same flow as other portions. Without more information, I can not see how an energy balance will help solve the problem.

- Q: How dose the heat pump transfers from cold to hot body ?

- Normally heat flow direction is high to low temperature zone when no work is input . But if external work is spent, then heat may flow in reverse direction also as per the thermodynamic principle. Heat pumps ( refrizerator, air conditioners etc.) follow above principle

- Q: how to make use of the heat evovled from diesel engine?

- Diesel engines need that heat to run efficiently. If you remove too much of it, through radiators or heat exchangers, you will reduce the efficiency of the engine.

- Q: Can we use steam as fluid in plate and frame heat exchanger?

- Absolutely! Try to place it so that the steam flows downward in the exchanger and the other fluid flows upward. That way the condensed steam can easily return.

- Q: What are the pros and CONS of geothermal heat pumps from an economic, scientific, and environmental prespective.

- Contact your local expert Carrier dealer to learn about the energy efficient, cost-effective and environmentally-friendly geothermal heat pumps available for your home.

- Q: water keeps building up in heat exchanger pressure switch

- Probably because the pressure switch heats up during the day and when the night cool the pressure switch, the pressure switch housing 'breaths in cool air which condenses the moisture in the switch housing. If this is not an explosion proof housing, you might put a drain in the housing. Another solution is to orient the conduit hub toward the ground and install a drain seal so the moisture drains into the conduit hub and out the drain of the drain seal.

- Q: Okay I have my first HX sizing for a homework problem, and I have h and k values so I can find overall U. The problem I'm having is the fact that I'm given little info for the the delta T, I'm told I want to vaporize 6,000lb/hr methanol by passing steam through the shell side of a double-pipe HX (both components are at atmospheric pressure and steam condenses through the HX). I can use a steam table, but what about the methanol? How am I supposed to find the temperature when it's entering the exchanger?

- You can verify this by looking up the values for the heat of vaporization of methanol, but I would expect that it is much higher than the heat required to raise the temperature of the liquid methanol to its boiling point (from a reasonable temperature) so it probably won't have a significant impact on the design of your heat exchanger. The major portion of heat will be used to vaporize the methanol. Reasonable assumptions would be 1) start with methanol entering at room temperature, or 2) assume it's already at its boiling point. It would be interesting to see what difference it makes in your design - I'm thinking not that much. Hope this helps

- Q: I have a hot water heater that has two extra pipes coming out the side with shut off valves. The top pipe is hot to the touch and the lower one is cooler. This is all in addition two the two copper pipes coming on on the top and a 5th pressure release valve on the side.The hardware store guy said, after looking at a picture that it was a radiant heating system for either the floors or the ceilings. The owners manual refers to these outlets as quot;heat exchangersquot; and I've also hear the term boiler and side mount boiler thrown around on here when I asked about it.Can anyone explain what it is doing such as is the hot water constantly being pumped*circulated) or only when I turn the furnace on. I am in a mid level apartment with units above and below me. Am I paying to heat my neighbors floor above me? What would happen if I just shut off one valve etc. etc.

- The hot water heater comes with a commercial-grade heat exchanger for both residential and commercial applications and comes with MC-91-1US digital controller with error code indicator. Both natural gas and propane models are available and the hot water heater comes pre-set at 120 degrees F. All LS units contain a newly designed commercial-grade heat exchanger for maximum durability.

- Q: PF Heat exchanger is shown in drawing. Engineering field exchanger using to cool the line. In Petrochemicl plant what does this mean by P F?

- sorry, my first guess was wrong ;) 10 points for the guy below ;)

Send your message to us

Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords