The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

Nominal heat transfer areaNominal heat transfer areaNominal heat transfer area | Channel Spacing | Calculate heat transfer area | handling capacity(flow rate: 1m/sec) | Nozzle nominal diameter | Model | I6T quality II6T quality | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

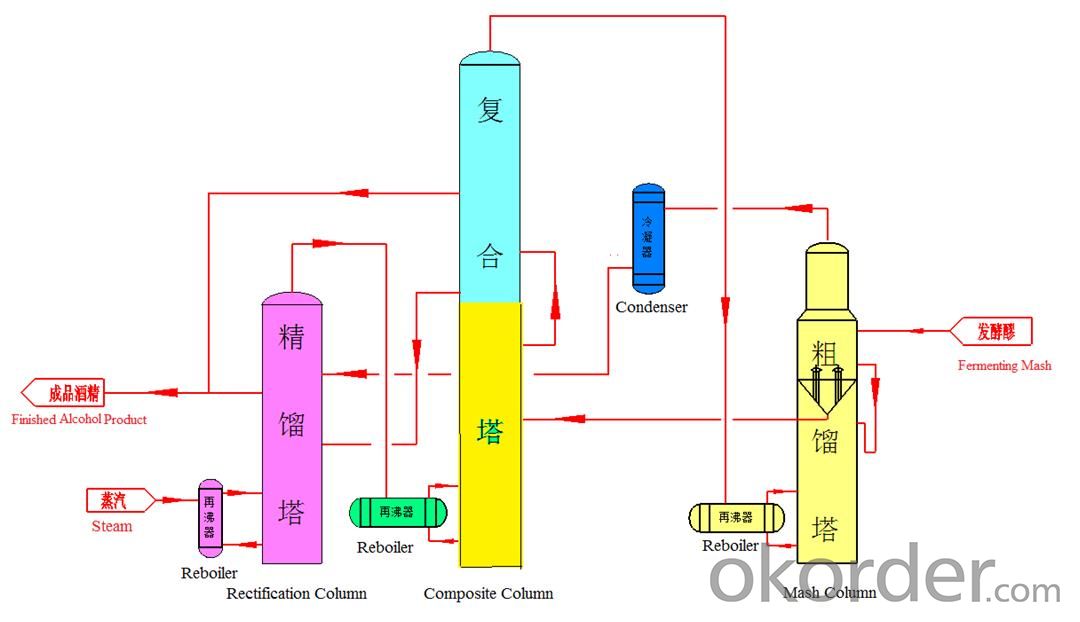

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: Hello to everyone,I have a question to ask.I have currently beenrenting a 3 bedroom home since 2002 that has central andmy gas bills are reallly high during the winter.On average itruns a little over $300 per/month.It is a very old unit.I have seenfriends and family gas bill during winter who have space heatersno central unit and their gas bill is significantly lower.The landlordsays I can install space heaters since lines are alreadyin place in each individual room.what I would like to knowis will my gas bill be noticably low using 10,000 btu space heatersto heat the home? I was told that central heat/air is the mostexpensive gas heat and that by electing to use space heatersI will see a drop in my utility bill. does anyone know or can estimatewhat my bill will be reduced to from $340-380 collectively?

- Is this a hot water system or a system that uses a gas furnace to heat the air directly? If it is one that heats the air directly I would be concerned about the condition of what is called the heat exchanger that separates the combustion gases from the room air as it is heated. How often has it been serviced? These can develop cracks and let carbon monoxide into your living spaces. This is the same problem you will have with space heaters. Unless they are the vented type, there will be some carbon monoxide generated when you use them and it can accumulate without you realizing it. That can be deadly. Space heaters can be more economical if only because you can use only those you need in the rooms you are in and not heat the whole house all of the time. If you opt to go with space heaters. at a minimum you need to get some carbon monoxide monitors from HomeDepot. You will also need a way to keep some fresh (outsided) air coming into the rooms you are heating. You also need to place a space heater where it won't set the drapes, bed covers or other flammable items on fire. Space heaters that can tip over are also a concern. The best of all worlds is vented space heaters. We used to have these in my folks house and they really worked well. Kept the house warm as toast. To make any kind of estimate you will need to know how much gas you are using now with the central heat and how much the space heaters will consume. Natural gas has about 1000 BTUs per cubic foot of gas or a million BTUs per thousand cubic feet of gas.

- Q: I installed a wood boiler and put the heat exchanger in the plenum and was wondering if i should increase the blower speed, it seems the heat exchanger is restricting some air flow to the vents.

- Blower-speed is a calculation based on the CFM needed against the exchange temperature involved. If the exchanger gets very hot, you will need to speed up the fan to remove the excess heat. But you should do this by calculation rather than by guess. Further to this, the amount of CFM your system can pass will be based on the supply and return duct sizes - so there will be top limits beyond which there is no benefit. Also which can be calculated.

- Q: in what form is waste heat expelled from an automobile engine?

- The form is heat. The means are through the radiator and heater cores (heat exchangers)

- Q: Am going to heat a one type of liquid (S.G of liquid is 1.2) via heat exchanger the inlet water is 98deg.c and the liquid gain 15 deg.c. what is the out let temperature of water?Note:- We don't know the inlet temperature of liquid.

- The heat exchanger is a counter-current exchanger. Liquid in (T) ------>[ ]------> Liquid out (T + 15) Water Out <--------[ ]<------ Water in (98 deg C) (? deg C) To solve that problem, we should know the Temperature difference between the Liquid and Water at the inlet and outlet point. If the temperature of liquid at its outlet is assumed to be the same with the water entering the exchanger, then the Liquid leaving the exchanger at 98 deg C. Because 98 deg C = T + 15, then T = 83 deg C.

- Q: specify type of heat exchanger and fluid commonly used for an air conditioner?

- Specification is for the designer. I don't have the need or the authority to write specifications for ACs. But I can list them. A radiator (a pipe with fins on it) and some sort of freon like fluid (freon is no longer used) .

- Q: I had the heating company do a routine maintenance on my furnace today and they said I need a new heat exchanger. I have propane heat. The reason was that the flame is too red. He said it should be more of a blue color. He cleaned it out a bit and said the color improved but I still should get a new heat exchanger. Afterword I did a little internet research. It seems the most common reason for a new heat exchanger is that you have a cracked one. He never mentioned that. Does what I am saying make sense? Does getting a new heat exchanger improve my flame color?Thanks!

- You were smart in your research, the heat exchanger beyond the flame, therefor does not affect the flame. The burners may need cleaned or replaced, gas regulator may need to checked. Don't know if you have a high efficiency unit that has forced cumbustion air or not, but that could be a source of your problem as well. But to put it in layman's terms, It ain't your heat exchanger.

- Q: Suppose you try to cool the kitchen in your house by leaving refrigerator door open. What happens? Why? Would the result be the same if you left open a picnic cooler full of ice? Explain the reason or any differences?

- it depends how long you leave the ref / cooler open. the ref has a continous supply off electricity that produces low temperature. if your kitchen is small and the cold does not dissipate quickly into the other rooms or outside the house, it will cool your kitchen... continously. in fact if you do this, ice will form to the edges of your chiller and you wont be able to close the door. now, the cooler has a limited supply of low temperature and your ice will melt... the kitchen and cooler will eventually reach an equilibrium temperature and then will drop til it reaches what you call room temperature (the temperature before you left the cooler opened). now, if the refrigerator is unplugged, it will behave the same way as the cooler.

- Q: I have a 30x40 woodworking shop, I installed a small cast iron stove, that I burn scrape wood in, on days when the temp. is down in the teens it takes for ever to heat the shop to a temp. that I can work,I wondered if a heat exchanger would be worth while.

- Heat transfers through the metal surfaces of the stove and as it travels up the flue (vent) pipe. Consider venting through lots of vent pipe that has a lot of surface area to transfer the heat into the room. The vent pipe can be the heat exchanger you speak of. If the heat were to be vented out in a direct straight shot, that would let the heat escape before transferring to the room. If it winds through lots of vent that is in the room, that will allow more transfer to the room.

- Q: My double door fridge gets warm in the fridge section at times.

- no its a sign of low coolant, if its less than 3 yrs old contact the manufacture,

- Q: Help!How much to repair? Can a handyman type take care of this problem?Heating system, forced air, comes on several times blowing cold air, before coming on and blowing hot air. What's wrong? Estimated cost to repair?I'm in the midwest!

- Nothings wrong.the air in the duct gets cold between cycles and takes a minute for the hot air to clear it out when system kicks on.Nothings wrong

Send your message to us

The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords