Raw Bauxite Price, Calcined bauxite Price, Bauxite Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Raw Bauxite Price, Calcined bauxite Price, Bauxite Price

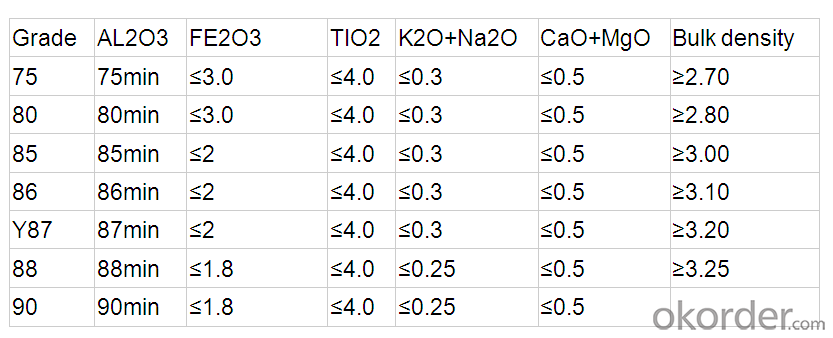

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

High grade calcined bauxite used for raw material of kinds of refractory products and monolithic series.

Usage

Calcined Bauxite used in

1.aluminium metallurgy,

2 refractory material,

3 precision casting,

4 aluminate cement

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q:what needs to be noted when choosing and using blast furnace fireproof materials?

- it depends on the size of the blast furnace. below 200 cubic meters alumina bricks and carbon brickcan be used. 200 cubic meters and above are currently integrated bottom, not the same as the size of the cubic level, varying in the use of refactory. I hope my answers above are helpful to you and your ideal anwers.

- Q:What's the heat conductivity coefficient, specific heat capacity and density of the refractory material of magnesite-chrome brick and magnesia-alumina brick respectively?

- It is suggested that you find some samples of well-known manufacturers, such as Ogilvy and Mather Group, and that will be more correct.

- Q:What is fire retardant coating mainly used for?

- Fire retardant coating is a coating which is applied to the surface of buildings and structures and can form a protective layer of fire retardancy and thermal insulation. It can reduce the flammability of the coated materials and block the rapid spread of fire so as to improve fire endurance of the coated materials. Features of fire retardant coating: (1) Fire retardant coating itself has a flame-retardancy or non-inflammability, and it can prevent the protected substrate from direct contact with the air, and delay ignition and reduce the burning speed of the objects. (2) In addition to flame retardancy or non-inflammability, the fire retardant coating itself has a a low thermal conductivity, which can delay the transfer of flame temperature to the substrate to be protected. (3) When heating, fire retardant coating decomposes non-combustible inert gas to dilute the combustible gas decomposed by the protected, making it difficult to burn or slow down the burning rate. (4) Fire retardant coating containing nitrogen will decomposite NO, NH3 and other basic groups, which compound with the organic radicals and interrupt the chain reaction so as to reduce the temperature. (5) intumescent fire retardant coating will expand and foam when heating, and form a carbon foam insulation to block the protected objects, thus delaying the transmission of heat to the substrate.

- Q:What is the definition and classification of amorphous fire resistance materials?

- 9.8. brick made of refractory bone material and powder material can be used directly or after adding appropriate liquid formulation Refractory paint. Refractory slinging material 6. Prefabricated cubes, bonding agent or other additives. fire-resistance sparying material compround additives. Refractory pressed into the material, binder. Refractory ramming material 3, The material is a new fire proof material without calcination Heavy aggregate and lightweight aggregate: Inorganic binding agent and organic bond, its fire resistance is not less than 1580. Refractory castables 2 mouldable refractory Classification according to the type of bonding agent: 1. Classification according to refractory aggregate. According to the production and construction method, refractory mud or refractory mire, with a certain proportion of the mixture

- Q:What is the the best matching ratio of refractory cement?

- The ratio of cement and sand is about 30 per cent. Properties and Applications of refractory mortar: 1, Good plasticity and easy construction; 2, High bonding strength and strong corrosion resistance; 3, Relatively high refractoriness up to 1650 ℃ ± 50 ℃; 4, Good slag corrosion resistance; 5, Good thermal peeling. Refractory mortar is mainly used in coke ovens, glass furnaces, hot blast furnace and other industrial furnaces. Applied industry: Metallurgy, building materials, machinery, petrochemicals, glass, boiler, electric power, steel, cement, etc. And refractory cement is also known as aluminate cement. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement. Aluminate cement is often yellow or brown or gray. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc. It is a special cement.

- Q:How can the furnace be replaced after the gasifier or water wall is replaced with refractory material?

- The simplest is to find a refractory construction unit, should provide you with oven curve.

- Q:what's the requirements of refractory for forge furnace?

- accurate answers please refer to Current Situation and Development Trend of Refractory Material in Heating Furnace ,Quality Requirement of Modern Industrial Furnace Refractory Material(GB/T17638-1998) Standard,Furnace-constructing Technology, if you need the mail box, please senf e-mail to me, my QQ number: 249704548.

- Q:What kind of material is refractory bauxite?

- Bauxite in refractory industry usually refers to the calcined bauxite ore which contains Al2O3 no less than 48%, while the content of Fe2O3 is rather low. Clinker of bauxite with high alumina is calcined bauxite. Tghe clinker is grey, light yellow and dark gray.

- Q:What are the refractory materials above 1000℃

- I have no idea what field you are in, and I am skillful at making refractory materials, because this is my job. You can send me an email informing your purpose, here is my email address .

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Raw Bauxite Price, Calcined bauxite Price, Bauxite Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords