Raw Materials for Refractory:Sintered Bauxite, Bauxite 85, Calcined Bauxite 88

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sintered bauxite, bauxite 85,calcined bauxite 88

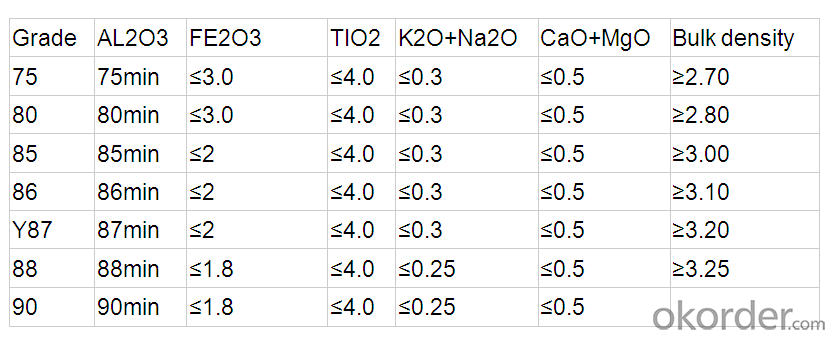

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Calcined bauxite

1) If you have special requirement for the specifications, we can have a talking to know if we can meet it. Usually, our skills and equipments are no problem. It's up to the production cost related to the bauxite raw ores we purchase;

2) Wide sizes variety is available as per customer's request.

Product Description:

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: How to use fire-resistant soil?

- It can live with water, not too sticky. Don't be too thin. It's best to put the stove in the inner wall.

- Q: What are the refractory stocks?

- The company produces energy saving, environmental protection type functional refractory materials and unshaped refractory materials. It is the main functional refractory material and unshaped refractory production enterprise in china. Company's products to new green high-quality refractory materials, energy saving and environmental protection as the leading iron and steel industry technological progress and improve the level of technology and equipment to adapt to meet the "development policy" refractories industry to develop industry, has a strong competitive advantage in the market. The main domestic refractory products company can only use part of the products of refractory materials production of iron and steel industry, iron and steel industry production and Pu resistant can be used in the vast majority of refractory products, iron and steel industry with the most complete refractory products. Therefore, the future development of the company is closely related to the prosperity of the iron and steel industry. More than more than 2000 enterprises in refractory industry, the company is the largest supplier of refractory materials in China, and the market share is less than 2%. Iron and steel group integration will inevitably lead to the overall contract cost control, supplier refractory decreases by seventy or eighty to two or three. The company's overall contract accounted for 37% (Montreal 68%), the overall contract increase will enhance the market share and profitability. China's urbanization, industrialization and investment in the 4 trillion infrastructure will stimulate sustained and rapid growth of China's steel demand. Therefore, in the long run, the prospects for the development of refractories for iron and steel are broad.

- Q: Urgently!! Refractory problems, online, etc.

- I feel that is the coating package, the coating of water is too large, the retaining wall in fused powder hydrated, can not produce strength under high temperature. What do you think?

- Q: Why does refractory need to add coarse firstly and then add fine aggregate?

- Oh, adding coarse aggregate first is to select good material to make aggregate, and the rest cna be made into fine aggregate. Because if it contains impurities, once being sintered, the appearance will be affected, but fine aggregate does not have this impact.

- Q: What are included in fireproofing materials?

- Incombustible?material of construction fire-proof material Grade A: Cement, stone, steel, coat, glass, aluminium alloy, ceramic tile, etc.; nonflammable material Grade B1: Fireproof?panel, rock wool.

- Q: What are the application of old refractory bricks?

- It can be used for refractory bricks again, as long as the quality is good. It is much more cost-effective than Bayerite.

- Q: How many types of fire-resistant material?

- 1. Acid fire-resistant material refers to one with more than 93% SiO2. It is featured by resistance to the corrosion of acidic slag ad high temperature and easy to react with alkaline molten slag. 2. Alkaline refractory material generally refers to one with magnesium oxide or magnesium oxide and calcium oxide as the main component. It has high refractoriness and strong resistance to basic slag. 3. Silicate aluminum refractory material refers to one with SiO2, Al2O3 as the main component. According to the content of Al2O, it can be divided into three categories: half siliceous (15-30% Al2O3), clay (Al2O3 30 ~ 48%), high aluminum (more than 48% of Al2O3). 4. Fused cast refractory material refers to shaped refractory products made by high temperature melting and casting.

- Q: Does the aluminum silicate thermal insulation material fireproof?

- it can be fireproof and has a strong fireproof?performance.

- Q: Are there any differences between insulation and refractory materials ?

- I will explain to you in a simple way. Refractory materials can resist more than 1200 degrees, some of which are not insulation materials, such as firebricks, which can directly contact with heat source, has little insulation effect. Ceramic fiber, high silica, etc. are all refractory materials which can insulate. Insulation materials with poor performance usually is lower than 800 degrees, which have large thermal resistance, and low thermal conductivity, high porosity. Thus they reduce the thermal loss. To put it simply, insulation materials store most of the heat and only let a small part of heat lose through the air, thus the heat has been isolated. Glass fiber, rock wool, flexible material for thermal insulation, etc. I hope you can understand it.

- Q: What are the additives and recipes of refractory?

- Water reducing agent is to evidently reduce mixing water content while keep the slamp value of refractory castable almost invariant, also known as fluid loss agent. Water reducing agent itself cannot have chemical reaction with material component or compose new chemical compound, but it just seemingly has physical and chemical reactions. The binding agent of refractory castable is calcium aluminate cement combined with clay and oxide micro powder. In commonly used water reducing agents, the inorganic includes sodium pyrophosphate (Na4P2O7), sodium tripolyphosphate (Na5P3O10), sodium hexametaphosphate [(NaPO3) 6], super sodium polyphosphate (Na2P4O11), sodium silicate (Na2O · nSiO2 · mH2O), and so on; the organic includes lignosulphonate water reducer (sodium lignosulphonate, calcium lignosulphonate); naphthalene water reducer (naphthalene sulfonate or naphthalene homologues with formaldehyde condensate): water soluble resin water reducing agent (sulfonated melamine formaldehyde resin, abbreviated as composite of melamine water reducer).

Send your message to us

Raw Materials for Refractory:Sintered Bauxite, Bauxite 85, Calcined Bauxite 88

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords