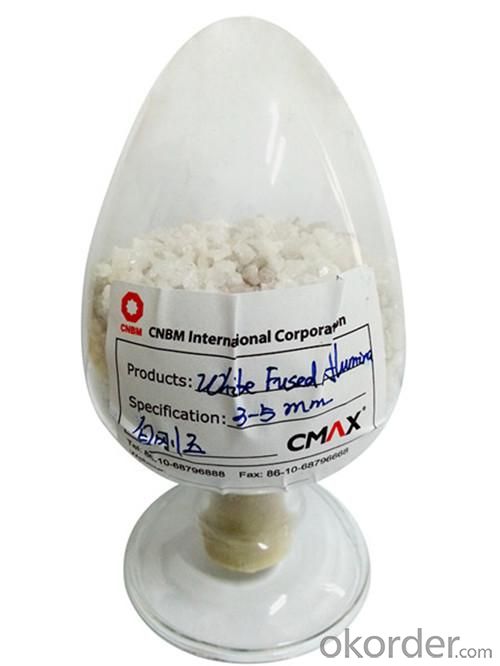

Raw Materials for Refractory:White Fused Alumina for Abrasive

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of White Fused Alumina For Abrasive:

Place of Origin:China mainland

Material:Aluminum oxide

Shape:Block

Color:White

Specifications of White Fused Alumina For Abrasive:

|

Al2O3 |

Fe2O3 |

SI020 |

Na2O |

|

99.20% MIN |

0.10% MAX |

0.20% MAX |

0.30% MAX |

Packaging & Delivery of White Fused Alumina For Abrasive:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Applications:

-Blast-cleaning

-Roughening

-Grinding, lapping and polishing media

-Reusable abrasive

-Ceramic grinding wheels and grinding media

-Wear-resistant and refractory products

Advantages

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: What are the refractory stocks?

- The company produces energy saving, environmental protection type functional refractory materials and unshaped refractory materials. It is the main functional refractory material and unshaped refractory production enterprise in china. Company's products to new green high-quality refractory materials, energy saving and environmental protection as the leading iron and steel industry technological progress and improve the level of technology and equipment to adapt to meet the "development policy" refractories industry to develop industry, has a strong competitive advantage in the market. The main domestic refractory products company can only use part of the products of refractory materials production of iron and steel industry, iron and steel industry production and Pu resistant can be used in the vast majority of refractory products, iron and steel industry with the most complete refractory products. Therefore, the future development of the company is closely related to the prosperity of the iron and steel industry. More than more than 2000 enterprises in refractory industry, the company is the largest supplier of refractory materials in China, and the market share is less than 2%. Iron and steel group integration will inevitably lead to the overall contract cost control, supplier refractory decreases by seventy or eighty to two or three. The company's overall contract accounted for 37% (Montreal 68%), the overall contract increase will enhance the market share and profitability. China's urbanization, industrialization and investment in the 4 trillion infrastructure will stimulate sustained and rapid growth of China's steel demand. Therefore, in the long run, the prospects for the development of refractories for iron and steel are broad.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- The preparation of a report or statement. During the compilation process, any problems should be actively communicated with the construction side. For example, dust collector selection, environmental protection investment, total emission approval. (especially the total emission, you must let the construction side and communicate with the environmental protection bureau to get the total amount, otherwise you write the EIA does not make any sense.) Generally speaking, the preparation of the report is longer, about forty days; and the preparation of the report table is shorter, about fifteen days.

- Q: Which are fire proofing thermal insulation materials?

- Fire proofing thermal insulation materials include: fire proofing heat insulating brick, fire proofing thermal baffle, fire proofing thermal insulation paper, fire proofing thermal insulation felt, fire proofing blocking, fire proofing fiber bulker, castable refractory, etc. Yizhen Decoration wish you a happy life!

- Q: What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

- Q: What material is used to make furnace pipe of refractory bricks?

- Furnace pipe of refractory brick is an indispensable part of casting cupola. Furnace pipe is divided into upper and lower part. Radial direction and axial breathing. The upper furnace pipe adopts double layer steel structure and countercurrent air supply mode. The lower furnace pipe is made by processing integrated heat resistant steel in flange, fin and inner wall in wearing parts. The operation life is over 3000h. There is radiating rib of heating air on the edge of furnace pipe liner by using the heat of casting cupola to heat air in cupola. Hot air temperature is about 180-250℃, which contributes to improve trhe thermal efficiency of production equipment, decrease production cost and improve economic benefit of enterprises.

- Q: what is the specs of thermal insulation refractory slab ?

- it is produced in accordance with scientific formula by using asbestos, glass fiber and potclay . it has strong tension strength capable of withstanding 1400 degrees Celsius, specifications!: 1.5DD20 (mm)

- Q: Fefractory of aluminium oxide.

- It can be refined into castable refractory and refractory bricks, according to temperature rating. There are shaped refractory material and shapeless refractory material, and ceramic fiber. So it must be specific. There is a large range of refractory, which basically contains the aluminium oxide.

- Q: What's the fire resistance test method of doors and roller shutters?

- Fire resistance test method of doors and roller shutters: This standard specifies the fire resistance test method for roller shutter doors under standard fire conditions. The method is used to test the fire resistance of the ventilating duct when bearing the external fire (A duct) and internal fire (B duct). Fire resistance test of vertical ducts may be conducted referring to this standard. 1.Test specimen1.1 The test specimen is obtained by cutting from any part of the qualified metal tube unless otherwise relevant standard or mutual agreement specifies the cutting position of the metal tube. 1.2 Length of the specimen: L≈2.5D+50mm (D: outer diameter of the metal tube). The cut surface of the specimen must be perpendicular to the axis of the metal , and the seamed edge of the cut should be round off. Test method GB243-82 of metal tube necking 2. Test procedures 2.1 In the test, punch or press the metal tube into the tapered conical seat (see Figure) with a hammer or press machine, and make it uniformly diminished to the regulated shrinkage X which is calculated according to the following formula: Test method GB243-822 for metallic pipe necking: The inner wall of the seat cover used in the test should be polished, and has certain hardness and is coated with lubricating oil. Its conicity is 1:10, 1:5 or others in accordance with relevant standard provisions. If there is no provision, then adopt the conicity of 1:10. This standard is not suitable for: a) The pipeline whose fire resistance depends on the fire resistance of the ceiling; b) The pipeline with access door, unless otherwise the access door is included into the pipeline and tested together; c) The pipeline with two or three sides; d) Fume exhaust pipes;

- Q: What is fire retardant coating mainly used for?

- The functions of refractory coating are as follows: 1. Non-intumescent fire retardant coating is mainly used for the fireproofing of wood, fiber board and other materials, and it is used in the surfaces of wood truss, roof, doors, windows and etc. Second, the intumescent fire retardant coating can be divided into non-toxic intumescent fire retardant coating, expansible fire retardant coating emulsions, solvent-based fire retardant coating. 3. Non-toxic intumescent fire retardant coating can be used to protect cables, polyethylene pipes and insulation board. 4, The expansible fire retardant coating emulsion and solvent-based fire retardant coating can be used for fireproofing of buildings, electricity power, and cables. 5. New fire retardant coating: Transparent fire retardant coating, water-soluble intumescent fire retardant coating, fireproof emulsion paint, polyvinyl acetate emulsion fire retardant paint, water-soluble intumescent fire retardant paint drying at room temperature, fire insulation coating polyolefin fire retardant coating, modified high chloropolyethylene fire retardant paint, chlorinated rubber fire retardant coating, firewall coating, intumescent coatings, wire and cable fire retardant paint, new fire retardant coating, casting fire retardant coating and so on.

- Q: What's the commonly used refractory material for ladle?

- 1. According to the refractoriness, it can be classified as follows: common refractory: 1580℃ ~ 1770℃; high grade refractory: 1770℃ ~ 2000℃; superrefractory: 2000 ℃; 2. According to the shape and demension of the product, it can be classified as follows: standard form : 230mm×113mm ×65mm of no more than four measuring scale, (demension ratio) Max: Min

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:White Fused Alumina for Abrasive

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords