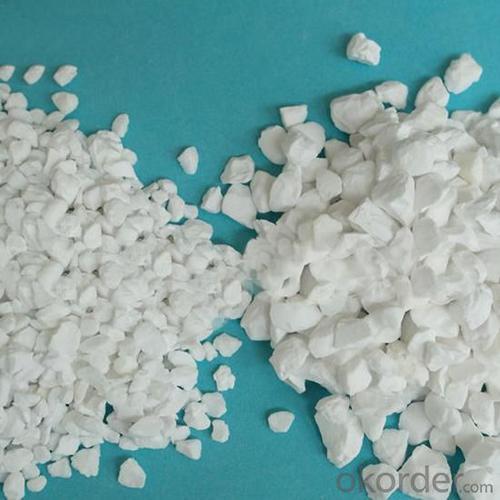

Sintered Tabular alumina

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Sintered Tabular alumina:

Place of Origin:China mainland

Material:Alumina Cement

Particle Shape:Block/Ball/Grain/Powder

Al2O3 Content(%):99.5%

SiO2 Content(%):0.02%

Color:White

Specifications of Sintered Tabular alumina:

|

Shape |

Type |

Chemical Compositon |

Physical Characteristics | |||||||

|

Al2O3 |

Na2O |

SiO2 |

Fe2O3 |

Bulk Density |

Apparent Porosity |

Water Absorption |

Packed Bulk Density |

Cold Crushing Strength | ||

|

≥% |

≤% |

≤% |

≤% |

≥g/cm3 |

% |

% |

Kg/m3 |

N | ||

|

Ball |

RP-T162 |

99.7 |

0.20 |

0.02 |

0.02 |

3.65 |

1.5 |

0.4 |

2160-2000 |

2900-14700 |

|

RP-T164 |

99.5 |

0.30 |

0.04 |

0.03 |

3.55 |

3.5 |

0.8 |

2000-1860 |

2700-13500 | |

|

RP-T60 |

99.3 |

0.40 |

0.09 |

0.02 |

3.50 |

5 |

1.5 |

|||

|

RP-T61 |

99.1 |

0.40 |

0.13 |

0.03 |

3.45 |

6 |

2.0 | |||

|

Granule |

RP-T60G |

99.3 |

0.40 |

0.10 |

0.02 |

3.50 |

5 |

1.5 |

(mm) 5-10 3-6 3-1 1-0 0.5-1 0.2-0.6 | |

|

RP-T61G |

99.1 |

0.40 |

0.13 |

0.03 |

3.45 |

6 |

2.0 | |||

|

Micro Powder |

RP-T60P45 |

99.2 |

0.40 |

0.09 |

0.02 |

3.50 |

5 |

1.5 |

(μm) -45μm (-325mesh) -20μm (-635mesh) | |

|

RP-T60P20 |

99.1 |

0.40 |

0.15 |

0.04 |

3.50 |

5 |

1.5 | |||

|

RP-T61P45 |

99.1 |

0.40 |

0.12 |

0.03 |

3.45 |

5 |

1.5 | |||

|

RP-Y61P20 |

99.0 |

0.40 |

0.15 |

0.04 |

3.45 |

5 |

1.5 | |||

Packaging & Delivery of Sintered Tabular alumina:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Application:

Widely used in iron and steel industry

Primary choice of refractory aggregate

Foundry, petrochemical, ceramic and incineration

Competitive Advantages:

High purity

High refractoriness

High volume stability

High density, low permeability

High thermal shock resistance

High chemical resistance

High mechanical stability

High wear-resistance

Timely delivery & service

Good company reputation

- Q: what's the application of fireproofing abs materials?

- ABS alloy shell, a toy of child, low load bearing, refrigerator lining, it can be processed into various wear-resisting sheets, plates,and has good electrical performance, it can be used as electronic components or auto parts, all kinds of insulation materials, it's easy to machining on the surface, so it can be made into designated special products (such as electroplate), and easy coloring,

- Q: What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- Ceramic fiber cloth is high temperature resistant and its continous use temperature can be up to 1000℃. It has high temperature resistance, low heat conductivity, thermal shock resistance, low thermal capacity; superior insulating property at high temperature, long service life; resistance to nonferrous metals like molten aluminum and zinc erosion; low and high temperature strength; innocuity with no adverse effect on the environment; and it is easy to install.

- Q: Is the ball mill used in production of refractories?

- It will be used. It is used in the process of milling the raw material which is less demanding on technology and in relatively large amount. Is there lots of network marketing for refractory industry? Is the competition fierce on the Internet?

- Q: I want to know what is the slim in the refractory bricks

- lining brick and refractory clay in the teeming ladle; high alumina brick, high alumina lining brick and high alumina refractory mortar can make cement kiln and glass melting furnace in the building materials industry for anti-slide. Taiyuan in Shanxi province is the famous place of origin; hard paste in the refractory clay is used as blast furnace refractory: // b, in agriculture as a fertilizer high alumina clay is also used in oil wells, which generally do not dip in water; accounting for 2/3 of abrasive products in the metallurgy, hard and semi-hard clay can be manufactured as ceramics for daily use. what you said should be slime. High-alumina clay can be resistant to high temperature after calcination! Refractoriness refractory clay refers that the refractoriness is more than 1580 ℃ with greater hardness and specific gravity and high refractoriness. except higher refractoriness, such as aluminum sulfate, the dosage accounts for about 70% of refractories; refractory clay and high alumina fused cast brick are widely distributed in China.

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- The material is very troublesome, it might crack horrendously if not baked well and all of them may be scraps after being took out from the furnace. Magnesia hydration is inevitable during the baking process. As volume expansibility of magnesite reaches 200%, so it is easy to crack. The key to bake is to quickly rule out the water vapor in furnace, especially within 150 degrees Celsius. After quickly ruling out the water vapor in furnace to avoid excessive reaction with magnesia of 150 degrees, it can be operated in accordance with convention. In addition, you should pay attention to the heat sources, for which i recommend electrical and coke to avoid generating a lot of water vapor during the natural gas combustion process which will worsen the situation.

- Q: which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q: What is the main material of fireproof wooden door?

- Fireproof wooden door has a lot of materials! including imported timber decorative effects: utilizing the diversity and easiness to cut of the timber, with all the decorative characteristics of the timber. Material selection features, door frames: Using high-quality hardwood, such as imported miscellaneous wood, camphorwood, lauan, hemlock, etc., insetting fire and smoke proof adhesive tape

- Q: Who can tell somthing about how to choose fire resistant rating of fire resistance rolling shutter doors?

- There is no necessary connection between them. Different fire resistant ratings of bulidings require different fire endurance of different elemements of buildings. According to the fire endurance, fireproof doors can be divided into A-grade, B-grade and C-grade, whose fire endurance should not be less 1.2h, 0.9h and 0.6h respectively. A-grade fireproof doors can be even applied to the material whose fire resistant rating is at secondary level. "Building Regulations" mention that fire resisting shutter can be used as partition of fire?compartment in those places where setting firewalls is not so easy. When using fire resisting shutter whose fire endurance doesn't include unexposed surface temperature rise, it should install closed independent automatic sprinkler system for protection on both sides, and the sprinkler sholud last at least 3 hours.

- Q: What is the limit of fireproof rolling shutter?

- According to the national standard 14102-2005 GB standard, the provisions of 14102-2005 GB specify that: According to provision 14102-2005 GB: If fire resistance limit of fire resisting shutter is no less than 3 hours, it is AAA fireproof rolling shutter. Therefore, the fire resistance limit of AAA grade fireproof rolling shutter should be 3 hours.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Sintered Tabular alumina

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords