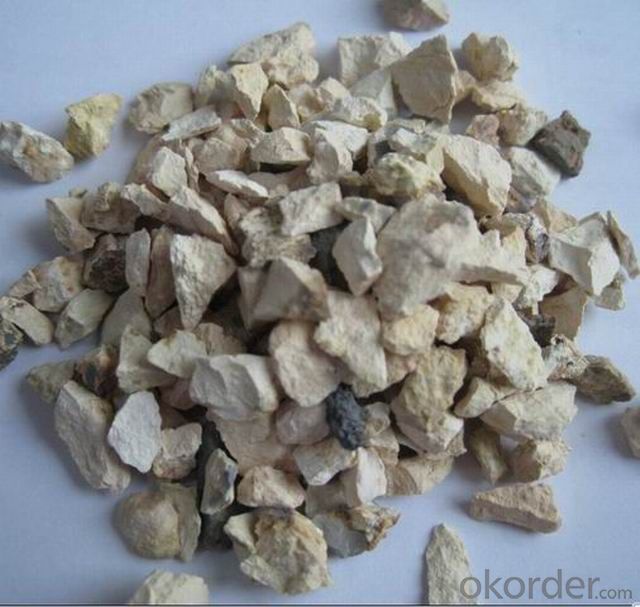

Al2O3 88% Calcined Bauxite of China Bauxite Ore

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Mingyue Bauxite and Calcined Bauxite:

Mingyue Bauxite, ie. bauxite ore, whose main content is Aluminium oxide with, who is department of hydrated

alumina containing impurities in appearance of earthy mineral;

Mingyue Calcined Bauxite is burnt bauxite, who is used for producing the existing uneven materin in nature --

alumina and aluminium. The purpose of calcining bauxite is to remove crystal water and improve the content of alumina.

Mingyue Bauxite Secification:

Al2O3 | Fe2O3 | TiO2 | K2O+Na2O | CaO+MgO | Bulk density |

≥65 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.6 |

≥75 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.7 |

≥80 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.8 |

≥85 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.0 |

≥86 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.1 |

≥87 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.2 |

≥88 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

Mingyue Refractory Bauxite Level:

Level | Chemical Composition (%) | Refractoriness (℃) | Bulk Density (g/cm3) | ||

Al2O3 | CaO | Fe2O3 | |||

superfine | >85 | <0.6 | <1.4.0 | >1790 | >3.6 |

first grade | >80 | <0.6 | <3.0 | >1790 | >3.0 |

second grade+1 | 70~80 | <0.8 | <3.0 | >1790 | >2.8 |

sencond grade | 60~70 | <0.8 | <3.0 | >1770 | >2.65 |

third grade | 50~60 | <0.8 | <2.5 | >1770 | >2.55 |

Product Uses

Mingyue Bauxite and Calcined Bauxite:

1. Aluminum industry;

2. Precision casting;

3. Refractory industry;

4. Silica acid aluminum firefibre;

5. Mixed with magnesium oxide, it can be an nice bonding agent, especially for pouring entire steel teeming ladle lining;

6. Manufacture bauxite cement, grinding abrasives;

7. Ceramic industry, and chemical industry for making aluminium compounds.

- Q:How is the development of Xinmi refractories industry? What's its advantages and disadvantages?

- The disadvantage is too small yard, vicious competition among each other and confusion in the market, which should be the inferiority of national refractory industry . Xinmi Refractory is well developed in recent years, mostly acidic and neutral refractories. It is still relatively rare to use in iron parts, steel pile with a satin and other basic refractory slide .

- Q:How many types do refractory bricks have? Where the quality of refractory material is best? What is the model?

- Sinosteel Luoyang (Luoyang Refractory Material Plant in the past): High alumina(mainly blast furnace), Gongyi. There are also a series of high-tech materials (silicon carbide, carborundum, etc.) a major producer of high alumina; silicious: Resistant material for steel, glass furnace, cement kiln); magnesia. Divide from uses and divide from chemical texture; silicious(glass furnace): Xinmi, Hennan Province, Lengshui River, coke oven, etc.). As for the models, Yixing and Changxing in Jiangsu Province: Haicheng, Liaoning Province; silicious, I do not understand your intentions; magnesia (nonferrous, steel refining; magnesia: High alumina brick; Dashiqiao area! Please put it in detail.

- Q:What do we mean by saying that a ladle cover knots, elbow knots, blowpipe knots in refractory materials? What is the “knot”?

- Go eastward 200 meters from the south gate of cultural square.

- Q:Does anyone know the difference between refractory and thermal insulation material?

- I will give you a relatively simple analysis. Refractory can bear above 1,200 degrees centigrade, but some refractory is not insulated. For example, refractory brick can be directly in contact with heat source, but it has little insulation effect. Refractory includes ceramic fiber, high silica and so on. And they can be also insulated. But insulation effect is not so good as insulation material. Insulation material generally can bear below 800 degrees centigrade, and it is large in thermal resistance, low in heat conductivity coefficient and high in porosity factor, thus reducing heat loss. Briefly speaking, insulated material is to store most heat, and just let a small quantity of heat run of through air, thus insulating heat. Refractory includes glass fiber, rock wool, aerogel blanket and so on.

- Q:Who can tell me what is neutral refractory?

- Refractories mainly refer to aluminum oxide, chromium oxide and carbon as the main component of refractory materials, such as corundum brick, high alumina brick, and carbon brick. Its characteristic goes to the resistance to both acidic and basic slag. Basic refractories mainly refer to the refractory materials whose mian components are magnesium oxide and calcium oxide, including magnesia bricks, magnesia-alumina bricks, magnesia chrome bricks, dolomite bricks, etc. Basic refractory is good at resisting basic slag erosion.

- Q:What's the refractory material?

- Frequently used refractory material: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia. In general, the refractory material include the above. For more information, you can ask for specific advice.

- Q:What are the material requirements of class A fire resistant door ?

- What are the material requirements of class A fire resistant door ?

- Q:What is the type of heat resistance property of high temperature electric furnace ?

- According to the levels of refractoriness : Common refractories: & Gt: 1580 ℃ ~ 1770 ℃ advanced refractories: 1770 ℃ ~ 2000 ℃ AAA refractories; 2000 ℃

- Q:Who knows what material is in the center of fireproof rolling curtain?

- In fact, in general, the middle of fire roller shutter is fire prevention materials, filled with asbestos fire protection materials in the fire shutter door of the two layer of iron sheet. I hope my answer can help you

- Q:I want to consult the fire resistant level standards of external wall thermal insulation materials.

- 1, The thermal insulation material that has level A combustion performance: Spraying inorganic fiber, glass wool, foam glass, ceramic foam, rock wool, foam cement and perlite obturator, and so on. 2, The thermal insulation material that has level B1 combustion performance: Special processed extruded polystyrene board (XPS) / special processed polyurethane (PU), phenolic and polystyrene powder. 3, Thermal insulation materials that have level B2 combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See article 4.3.6 in the 2009 edition construction technical measures. Level A insulation material is just for fire protection, so its thermal insulation performance is worse than the organic XPS or EPS materials. Hope this will help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Al2O3 88% Calcined Bauxite of China Bauxite Ore

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords