Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 85% Powder

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

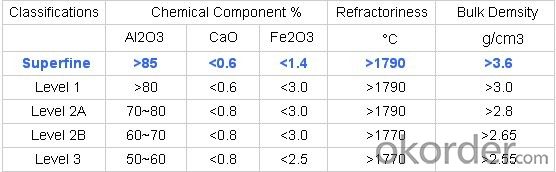

Calcined Bauxite Specifications

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Pictures:

- Q: Who know what kind of fire shutter fire rating are there?

- Fire resistance rating of the building elements is different due to the different requirements of the construction . Fire proof door can be divided into Serie A, B and C in terms of fire endurance limit, fire resisting limit are not should be less than 1.20h, 0.90h and 0.60h. That is, if the fire resistance rating is two, also it is possible to use a class a fire door. Hope my answer will help you.

- Q: What are the refractory stocks?

- The company produces energy saving, environmental protection type functional refractory materials and unshaped refractory materials. It is the main functional refractory material and unshaped refractory production enterprise in china. Company's products to new green high-quality refractory materials, energy saving and environmental protection as the leading iron and steel industry technological progress and improve the level of technology and equipment to adapt to meet the "development policy" refractories industry to develop industry, has a strong competitive advantage in the market. The main domestic refractory products company can only use part of the products of refractory materials production of iron and steel industry, iron and steel industry production and Pu resistant can be used in the vast majority of refractory products, iron and steel industry with the most complete refractory products. Therefore, the future development of the company is closely related to the prosperity of the iron and steel industry. More than more than 2000 enterprises in refractory industry, the company is the largest supplier of refractory materials in China, and the market share is less than 2%. Iron and steel group integration will inevitably lead to the overall contract cost control, supplier refractory decreases by seventy or eighty to two or three. The company's overall contract accounted for 37% (Montreal 68%), the overall contract increase will enhance the market share and profitability. China's urbanization, industrialization and investment in the 4 trillion infrastructure will stimulate sustained and rapid growth of China's steel demand. Therefore, in the long run, the prospects for the development of refractories for iron and steel are broad.

- Q: I wanna ask that magnesium oxide is refractory?

- Yes, Magnesia belongs to ionic crystals, the oin of magnesium has two charge, oxygen and magnesium ions are relatively small radius, these two factors make a lot of magnesium oxide lattice energy, high melting point is up to 2800 degrees Celsius. Because the magnesium oxide is stable and not react with water, it is widely used as a refractory material.

- Q: I wanna ask about the building insulation materials fire rating?

- the classfication of building insulation materials fire rating: 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: What's the difference between refractory metal raceway and fireproof raceway?

- In terms of fire protection, fireproof raceway means that it is composed of the material with certain combustion performance and generally made of flame retardant or incombustible?material. While for the refractory raceway, according to GA 479-2004 "Fire Resistant Cable Tray", its most important properties are: Fire resistance of the cable tray should meet with the following requirements: The cable tray of I grade fire resistance should keep the working time more than 60min, of II grade fire resistance should keep the working time more than 45min, and of III grade fire resistance should keep the working time more than 30min. Hope this is helpful for you! Thank you.

- Q: What kind of material is refractory fiber?

- Refractory fiber is good infrared radiation material with good thermal capacity and infrared heating effect. The use of firefractory fiber products can effectively save energy. It is an ideal energy-saving material. Practice has proved that using refractory fiber in continuous industrial heating furnace can save energy of over 15%, and using it in interval industrial heating furnace, it can save energy of more than 30%, while increasing productivity and improving product quality. And make the furnace structure light, large-scale with good comprehensive performance. Refractory fiber is soft and flexible and it is also ideal sealing material. As it has good insulation, sound absorption, anti-oxidation, oil and water resistance and easy construction, it is widely used in metallurgy, building materials, petroleum, chemical, shipbuilding, electric power, aerospace and other fields.

- Q: What refractories have good mechanical property resistance and heat expansion and cold contraction property?

- Explain that where you use it for and what requirements you have. Follow-up: I use it in metallurgical furnaces with the features of strong stirring and acidic residue.

- Q: Which refractory quality inspection authority is good?

- Of course, it is Research Institue of Refractory Materials in Luoyang, Henan. In fact, what we want is accuracy and authority. Quality and inspection costs, which is more important?

- Q: How should refractory cement be used?

- Refractory cement is very easy to use. Add some water and mix, and it will harden. Generally there is no need to add other binding agents, but you can add some refractory aggregate and powder. If you use only refractory cement, it will generate a lot of cracks after high temperature. Generally refractory cement can withstand temperature of about 1300 degrees.

- Q: What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords