Raw Materials for Refractory:Calcined Bauxite Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite Powder

Calcined Bauxite Introduction

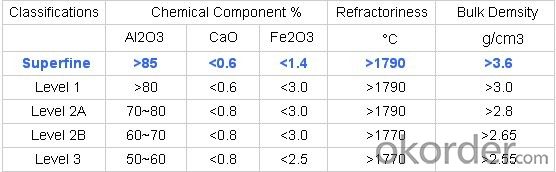

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

Calcined Bauxite Specifications

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

6. Producing bauxite cement

7. Abrasives

8. Ceramics industry

9. Chemistry industry for all kinds of aluminium compound.

Pictures:

- Q: What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q: What is the strength of high strength refractory material?

- Hefei Jiule decoration is answering your question: Use corundum as aggregate, high alumina cement as binder, mixed with a number of additives prepared, with high strength, and a hydraulic refractory casting material used in hot furnace lining at high temperature.

- Q: whether the fire resistant level of aerated concrete building blocks can reach the grade one?

- Aerated concrete building blocks is made by calcareous materials (such as cement, lime) and siliceous material (such as sand, fly ash, slag), adding aluminum powder ingredients as filling agent, by mixing with water, casting molding, gas - expansion, raising the pre-cut, and then the high-pressure steam curing of silicate building blocks. when aerated concrete is at the temperatures below 600 ℃, the compressive strength will be increased slightly, when the temperature is at about 600 ℃, the compressive strength is close to the compressive strength at normal temperature, so the aerated concrete, as building materials, the fire performance can meet the national fireproffing safety standards level.

- Q: How to count the construction costs of refractories?

- In winter, the temperature of the the fire-resistant masonry, fire-resistant plastic, sodium silicate, phosphoric?acid castable should be maintained above 5 ℃. Usually greenhouses in which heating facilities are installed to maintain the appropriate temperaturere for the construction environment should be erected in refractory masonry. The temperature around the construction site of the industrial furnace and refractory masonry shall not be lower than 5 ℃.

- Q: What is the concept of lightweight refractory material?

- Lightweight refractory material has high porosity, mechanical strength and erosion resistance. Compared with normal refractory bricks, it is a kind of refractory material with large volume shrinkage in high temperature, low thermal conductivity and small bulk density. It is used as thermal insulation material in industrial furnace and other thermal equipments. It has poor wear resistancel.

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: whether the aluminum silicate thermal insulation material is fireproof or not?

- Yes, it is fireproof. Refractory thermal insulation material mainly refers to the inorganic thermal insulation materials and composite thermal insulation materials. According to the shape it can be divided into: Fibrous finishing, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber,ect.. it takes the flint clay clinker as raw material, produced by the fusion of resistance or electric arc furnace and the injection of fiber forming. characteristic: Low thermal conductivity, excellent thermal and chemical stability, without binder and corrosive material.

- Q: What is the particle size of boron carbide for refractories?

- 0.3-0.5% is OK, but also with other additives, such as aluminum powder, silicon powder, magnesium alloy powder and so on. To achieve good results.

- Q: What are the differences of ceramics and refractories? Is the ceramics belonging to refractories?

- They are not the same. If you say the ceramic fibers, they have some common points because the ceramic fiber is one of the refractory. It is belonged to the lightweight refractory which can be considered a new type of refractory with the main ingredient of aluminum silicate (including aluminium oxide and silicon?dioxide).

- Q: Which basic refractory is better?

- The following companies are good: 1, Xuzhou Reka Casting Material Co., Ltd. Address: No.22-2 Luoshan Road, Economic and Technological Development Zone, Xuzhou, Jiangsu. 2, Golden Triangle Refractory Plant, Xinmi, Henan. Address: Ganzhou Street, Litang Village, Xinmi City, Henan. 3, Zibo Sun Refractories Co., Ltd. Address: Wujia Village, Shangjia Town, Zichuan(Wenchang Lake) District, Zibo City, Shangdong.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords