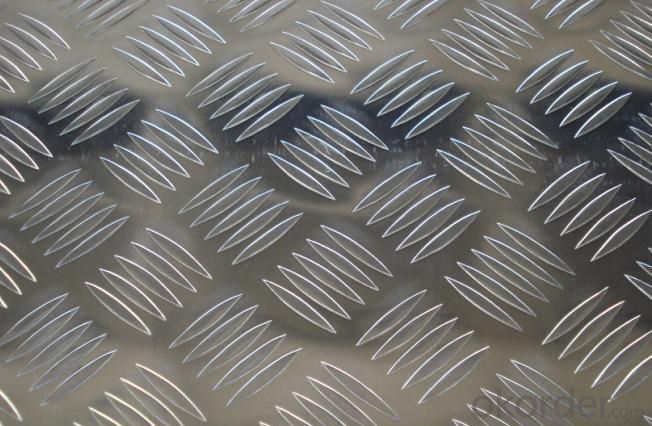

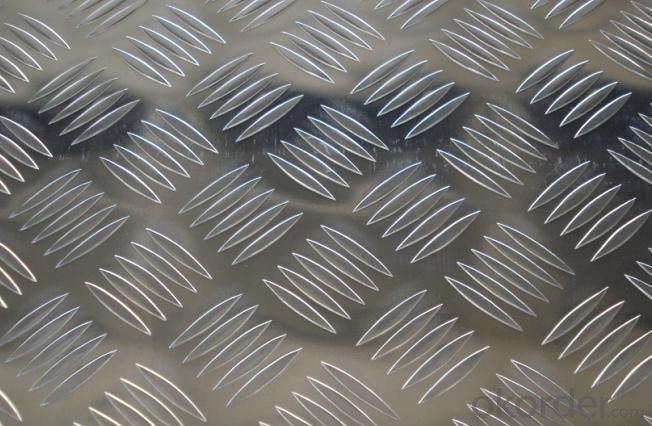

Race Car Aluminum Sheets - Decorative Embossed Aluminum Sheet from Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy | 1100/1050,1060,1070,3003,3105,5052,5083,8011 | ||

Temper | O, H12,H14,H16,H18,H22,H24,H26,H32 etc | ||

Specification | Thickness(mm) | 0.1mm-3.0mm | |

Width(mm) | 20mm-2200mm | ||

Application | Roofing, Refrigerator, ornamental and decoration, etc | ||

Inner Diameter(MM): | 75/150/200/310/505 | Standard: | GB/T3190-1999.GB/T3190-2003. YS/T430-2000 |

Surface Treatment | two bars/ three bars/ five bars/ stucco | ||

Origin | China | ||

Payment | 30% by TT in advance as deposit and 70% balance by TT or L/C at sight | ||

Lead Time | Within 10-25 days after receiving deposit or L/C copy | ||

Packaging & Shipping

1. For sheet, 18-20MT can be loaded into 20 foot container, we try to use 20 foot container, the sea freight rate is much cheaper than 40 foot container.

2. The packing is very strong, which has 3 lays, thick fiber, foam, plastic, enough drying agent, suitable for long distance sea transportation.

The application of the embossed aluminum sheet/coils:it is widely used in air-conditioning,cable,exchanger, cigarettes,food,medicine,decoration,packing, electrical,electric products and etc.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Aluminum has to be extracted from the earth which is costly and takes a lot of energy. Then the aluminum needs to be smelted out of the rock that it is in, again this takes a lot of energy and creates toxins. Aluminum like all metals are finite, we conserve resources and the land where they will need to be extracted by recycling it.

- Q: Nissan A1100P aluminum plate is equivalent to what brand of domestic, where there are relevant information and instructions, mechanical design manuals or other materials manuals? Thank you.

- 1, aluminum plate A1100P equivalent to national standard AL1100 aluminum plate.2 and 1100 are pure aluminium, the content of aluminium is 99%, which can not be improved by heat treatment. With high corrosion resistance, electrical conductivity and thermal conductivity, and its small density, good plasticity, through pressure processing can produce all kinds of aluminum, but the strength is low. Other process properties are basically the same as those of 1050A. 1100 commonly used to have good machining performance, high corrosion resistance, high strength does not need not see, such as video and chemical handling and storage equipment, sheet metal products, hardware, hollow spinning drawing goods welding key combination, reflector, nameplate.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- Aluminum plate can not be called grade, I give the high-speed rail processing bending sound barrier is aluminum, bending effect is very good.

- Q: Are aluminum sheets suitable for chemical storage containers?

- No, aluminum sheets are generally not suitable for chemical storage containers as aluminum is highly reactive and can corrode or react with certain chemicals, leading to potential leaks or contamination.

- Q: Do these frames rust? For example here is a link. But I am genuinely curious because in swimming pools, the hand rails going into the swimming pool have the same finish as this bike frame and they have white corrosion marks. Thank you in advanced

- Rust refers to the oxidation of iron, so no it doesn't rust. Aluminium oxidates rapidly which usually increases its corrosion resistance. 6061 is a pretty standard aluminium alloy, which shouldn't corrode under normal circumstances. Certainly not in a well designed and maintained bicycle. Things that could decrease the corrosion resistance of your aluminium bike include: - contact with other metals that have a higher valence (+ contact with water). Could be caused by a poorly designed bike, but not very likely. - contact with chemicals/salts/alkalis - narrow spots (where water could be trapped) caused by poor design, production faults or a damaged surface. Corrosion in your swimming pool could be caused by the chemicals you use to kill the bacteria in the pool. How do you know it is the same material though?

- Q: Can aluminum sheets be used in cryogenic applications?

- Yes, aluminum sheets can be used in cryogenic applications. Aluminum has excellent thermal conductivity and low temperature properties, which make it a suitable material for cryogenic environments. It can withstand extreme low temperatures without becoming brittle or losing its structural integrity. Additionally, aluminum is lightweight and has good corrosion resistance, making it a practical choice for cryogenic applications where weight and durability are important factors. However, it is important to ensure that the specific aluminum alloy being used is suitable for the intended cryogenic application, as different alloys may have varying properties and performance at low temperatures.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- The stadium opened in 1970, so that would be aluminum.

- Q: What are the common thicknesses of aluminum sheets used in construction?

- Depending on the specific application and requirements, the thicknesses of aluminum sheets commonly used in construction can vary. Some commonly employed thicknesses are 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are frequently utilized for architectural purposes, including wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), find use in heavier construction applications like structural components, support beams, and decking. It is worth noting that these thicknesses merely serve as examples and may vary depending on the specific project requirements and engineering specifications.

- Q: Are 101 aluminum sheets suitable for aerospace tooling?

- 101 aluminum sheets are not appropriate for aerospace tooling due to their lack of high strength, stiffness, and heat resistance. Aerospace tooling necessitates materials like high-strength aluminum alloys (such as 7075 or 2024) or even specialized materials like titanium alloys for more demanding tasks. These materials possess superior mechanical properties and can endure the rigorous conditions encountered in aerospace manufacturing.

Send your message to us

Race Car Aluminum Sheets - Decorative Embossed Aluminum Sheet from Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords