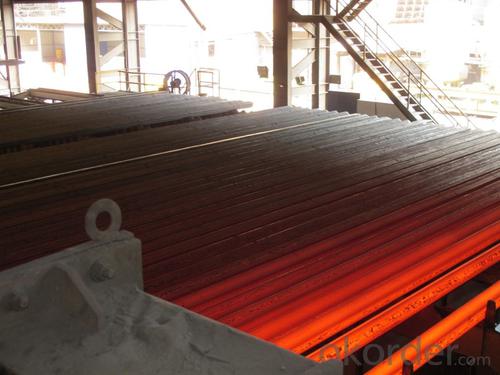

Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How is the demand for steel billets projected to change in the future?

- The demand for steel billets is expected to experience significant changes in the future due to various factors. One of the primary drivers of this change is the overall growth of the construction and infrastructure sectors. As economies continue to develop, there will be an increased need for steel billets to support the construction of buildings, bridges, roads, and other infrastructure projects. Additionally, the automotive industry is also anticipated to contribute to the changing demand for steel billets. With the rising demand for electric vehicles and the need for lightweight materials to improve fuel efficiency, steel billets may be replaced by alternative materials such as aluminum or carbon fiber in certain automotive applications. Furthermore, the renewable energy sector is another potential factor that could impact the demand for steel billets. As the world moves towards cleaner energy sources, there will be a growing requirement for wind turbines and solar panels, which are predominantly made from steel. This could lead to an increase in demand for steel billets in the manufacturing of these renewable energy components. On the other hand, advancements in technology and manufacturing processes may also influence the demand for steel billets. As new techniques and materials are developed, there is a possibility of steel billets being substituted by alternative materials or manufacturing methods that offer superior performance or cost-efficiency. Overall, while the demand for steel billets is expected to remain strong in the foreseeable future, it may undergo changes based on the growth of construction, infrastructure, automotive, and renewable energy sectors, as well as advancements in technology and materials.

- Q: Can steel billets be used for structural purposes?

- Yes, steel billets can be used for structural purposes. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes, including beams, columns, and other structural components. These billets are commonly used in construction and engineering projects to provide strength, durability, and load-bearing capabilities to structures. Steel billets are often further processed and shaped to meet specific design requirements before being incorporated into the construction process. They are widely utilized in the construction of buildings, bridges, highways, and other infrastructure projects due to their high strength-to-weight ratio and excellent mechanical properties. Additionally, steel billets can be easily welded, making them suitable for various structural applications.

- Q: What is the role of steel billets in the construction of power plants?

- Steel billets are an essential component in the construction of power plants as they serve as the raw material for manufacturing various structural and mechanical components. These billets are used to fabricate beams, columns, plates, and other elements that provide strength and support to the power plant's infrastructure. They are also utilized in the production of machinery and equipment required for power generation and distribution. Overall, steel billets play a crucial role in ensuring the durability, stability, and safety of power plants.

- Q: Are steel billets used in the shipbuilding industry?

- Steel billets are commonly utilized in the shipbuilding industry. They serve as semi-finished steel products, usually employed as raw materials for further processing. Within shipbuilding, these billets find application in the production of diverse structural components, including plates, beams, and bars, which constitute the ship's framework. The remarkable strength and durability of steel deem it an optimal material for ship construction, capable of enduring the challenging conditions of the marine environment. Moreover, steel billets possess the advantage of being easily molded and welded, facilitating the fabrication of intricate ship structures. Overall, the pivotal role played by steel billets in the shipbuilding sector revolves around supplying the essential raw materials necessary for constructing robust and dependable vessels.

- Q: How are steel billets used in the production of agricultural equipment?

- The versatility and durability of steel billets make them indispensable in the production of agricultural equipment. These semi-finished steel products come in solid rectangular forms, making them perfect for various manufacturing processes. When it comes to agricultural equipment production, steel billets serve as the primary raw material for forging, casting, or rolling. Forging involves heating the billets to a specific temperature and shaping them with a hammer or press. This method is commonly used to create robust components like plowshares, tiller blades, and harrow teeth that require superior strength and resistance to wear. Casting, on the other hand, involves pouring molten steel into a mold and allowing it to solidify. By melting and casting steel billets into intricate shapes, manufacturers can produce complex components such as tractor engine blocks, combine harvester parts, and agricultural machinery frames. This flexibility in shape allows for customized equipment that meets specific requirements. Rolling is yet another technique that utilizes steel billets in agricultural equipment production. The billets are heated and then passed through rollers to reduce their size and shape them into bars, rods, or sheets. Rolled steel billets are commonly used for manufacturing axles, shafts, and brackets, which are crucial for the proper functioning of agricultural machinery. The inherent strength and durability of steel billets make them highly preferred in agricultural equipment production. The demanding conditions of the agricultural industry require machinery that can withstand harsh environments, heavy loads, and repetitive use. Steel billets offer exceptional strength, enabling the creation of equipment that can endure these challenging conditions. Furthermore, heat treatment processes like quenching and tempering can further enhance the mechanical properties of steel billets. In conclusion, steel billets play a crucial role in the production of agricultural equipment. Their versatility and durability allow manufacturers to create components and machinery that can withstand the challenging conditions of the agricultural industry. Whether used in forging, casting, or rolling, steel billets provide the necessary strength and reliability for efficient and long-lasting agricultural equipment.

- Q: What are the specifications for stainless steel billets used in the food industry?

- To ensure safety and hygiene, the food industry requires stainless steel billets to meet specific specifications. These specifications focus on the stainless steel's composition, corrosion resistance, and ability to withstand high temperatures and aggressive cleaning agents. First and foremost, stainless steel used for food industry billets must contain a high percentage of chromium, typically ranging from 16% to 18%. This high chromium content ensures excellent corrosion resistance, preventing any reaction with food or cleaning agents. In addition, these billets should have a low carbon content, usually below 0.08%. By keeping the carbon content low, the stainless steel becomes less susceptible to sensitization, which can cause corrosion and contamination of food products. Furthermore, the stainless steel billets must adhere to specific international standards, such as ASTM A276 or EN 10088. These standards outline the minimum requirements for chemical composition, mechanical properties, and surface finish. Moreover, the surface finish of the billets is crucial in the food industry. It must be smooth and free from defects like pits or cracks to prevent the accumulation of bacteria and facilitate easy cleaning. The dimensions of the billets also contribute to their suitability for the food industry. They are commonly available in square or rectangular shapes, with various sizes depending on the specific application. Lastly, these billets should be certified and compliant with industry regulations, such as those set by the Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). In conclusion, stainless steel billets used in the food industry must meet specific requirements regarding chromium and carbon content, international standards, surface finish, dimensions, and industry regulations for safety and hygiene.

- Q: How are steel billets used in the manufacturing of power transmission equipment?

- Steel billets are used in the manufacturing of power transmission equipment as they serve as the raw material for various components such as gears, shafts, and housings. These billets are forged, machined, and shaped into the required sizes and shapes to create strong and durable parts that can withstand the high loads and pressures involved in power transmission. Overall, steel billets play a vital role in ensuring the reliability and performance of power transmission equipment.

- Q: What are the main factors affecting the dimensional stability of steel billets?

- The dimensional stability of steel billets can be influenced by various factors. These factors include temperature, cooling rate, composition, mechanical stresses, heat treatment, and manufacturing techniques. Firstly, temperature plays a significant role in the dimensional stability of steel billets. Depending on the temperature they are exposed to, the billets can undergo thermal expansion or contraction. To minimize dimensional changes, it is important to carefully control the temperature during the manufacturing process and subsequent cooling stages. Secondly, the rate at which the steel billets cool down after being heated also affects their dimensional stability. Rapid cooling can result in internal stresses and cause warping or distortion, while slow cooling can lead to uneven dimensional changes. Thirdly, the chemical composition of the steel billets is a crucial factor. Different alloying elements, impurities, and carbon content can influence the behavior of the material during heating and cooling. Higher carbon content, for example, increases the likelihood of warping or distortion. Moreover, mechanical stresses from handling, transportation, or machining processes can impact the dimensional stability of steel billets. Excessive bending, twisting, or pressure can cause permanent deformation or residual stresses, thus affecting overall dimensional stability. Furthermore, the heat treatment process also plays a role in the dimensional stability of steel billets. Different heat treatment methods can introduce internal stresses or phase transformations that may alter the billet's dimensions. Lastly, the manufacturing techniques used during the production of steel billets can have an impact on their dimensional stability. Inadequate control or inconsistencies in casting, rolling, or forging processes can result in variations in the billet's dimensions. Considering and controlling these factors is crucial to ensure the dimensional stability of steel billets. Any dimensional changes can have consequences for subsequent processing steps and the overall quality of the final product.

- Q: What are the different types of extrusion processes used for shaping steel billets?

- The different types of extrusion processes used for shaping steel billets include hot extrusion, cold extrusion, direct extrusion, indirect extrusion, and hydrostatic extrusion.

- Q: What is the role of steel billets in the manufacturing of railway wheels?

- Steel billets are the starting material used in the manufacturing of railway wheels. They are heated and forged into the desired shape and dimensions, forming the solid base for the wheels. The billets undergo various processes such as rolling, machining, and heat treatment to ensure the wheels have the necessary strength, durability, and dimensional accuracy required for railway applications.

Send your message to us

Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords