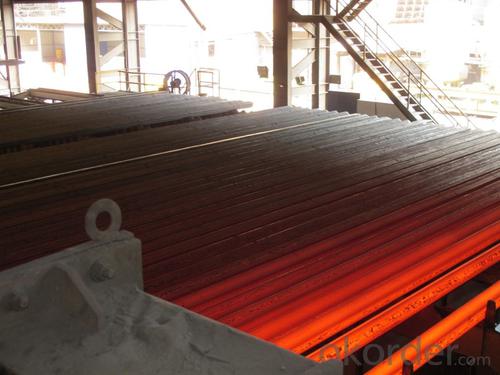

Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets labeled for identification purposes?

- To identify steel billets, a combination of alphanumeric codes and markings are utilized. These labels contain vital data regarding the billet's composition, size, and other significant particulars. The most prevalent approach to label steel billets involves directly stamping or engraving the necessary information onto the billet's surface. This includes details like steel grade, heat number, lot number, and the manufacturer's symbol or logo. These markings are typically made using durable and legible industrial-grade ink or via electrochemical etching, ensuring their resilience even in harsh environments. Additionally, steel billets may also carry identification tags or labels that offer additional information which cannot be easily engraved or stamped. These tags or labels may feature barcodes, QR codes, or RFID tags, allowing for quick access to relevant information through specialized equipment. By employing these labeling methods, steel billets can be easily identified, tracked, and monitored throughout their lifespan. This ensures effective quality control, inventory management, and efficient production processes within the steel industry.

- Q: Are steel billets used in the production of household goods?

- No, steel billets are not typically used in the production of household goods. Steel billets are semi-finished products that are used as raw material for various industries, such as construction, automotive, and manufacturing. They are usually hot-rolled into different shapes, such as bars, rods, or sheets, which are then further processed to create the desired household goods. For household goods, manufacturers often use specific types of steel, such as stainless steel or carbon steel, that have been processed and shaped according to the particular product requirements.

- Q: How are steel billets rolled into shape?

- Steel billets are rolled into shape through a process called hot rolling. This process involves heating the steel billet to high temperatures, typically above 1,000 degrees Celsius, to make it malleable and easier to shape. The heated billet is then passed through a series of rolling mills, which consist of a pair of cylindrical rollers that rotate in opposite directions. As the billet passes through the rollers, it is gradually compressed and elongated, resulting in a desired shape and size. The rollers apply high pressure on the billet, effectively reducing its thickness and increasing its length. This continuous rolling process allows for precise control over the shape and dimensions of the steel product. To ensure smooth rolling and prevent the billet from sticking to the rollers, lubricants are often applied. These lubricants also help in dissipating the heat generated during the rolling process. Depending on the desired final product, the steel billet may undergo multiple passes through the rolling mills to achieve the desired shape and dimensions. After the initial rough rolling, the steel may be further shaped and refined through additional rolling stages. Once the desired shape is achieved, the steel is then allowed to cool and solidify. This cooling process is crucial to ensure the final product has the desired mechanical properties and structural integrity. Overall, the hot rolling process of steel billets is a crucial step in the production of various steel products. It allows for the efficient shaping and forming of the billets into different shapes, sizes, and profiles, meeting the specific requirements of different industries such as construction, automotive, and manufacturing.

- Q: What is the average density of a steel billet?

- The average density of a steel billet can vary depending on the specific grade and composition of the steel used. However, on average, the density of a steel billet ranges from around 7,800 to 8,050 kilograms per cubic meter (kg/m³). This density value is higher compared to many other materials, making steel a dense and heavy material. The density of a steel billet is a crucial factor to consider when determining its weight, volume, and overall structural properties.

- Q: How are steel billets used in the manufacturing of tools?

- Steel billets are used in the manufacturing of tools as the starting material. They are heated, shaped, and machined into various tool components, such as cutting blades, drill bits, or molds, to achieve the desired shape and strength.

- Q: What are the main factors affecting the magnetic properties of steel billets?

- The main factors affecting the magnetic properties of steel billets are the composition of the steel, the crystal structure, the presence of impurities, and the manufacturing process used.

- Q: Can steel billets be used for making architectural structures?

- Yes, steel billets can be used for making architectural structures. Steel billets are commonly used as a raw material in the construction industry for various applications including the fabrication of beams, columns, and other structural components. The high strength and durability of steel make it an ideal choice for architectural structures, providing stability and structural integrity to buildings.

- Q: How are steel billets used in the production of construction components?

- Construction components rely on steel billets as a crucial raw material. These billets are utilized primarily in the creation of various structural elements like beams, columns, and bars, which compose the framework of buildings and infrastructure projects. The process commences with steel billets, semi-finished products formed by casting molten steel into rectangular or square shapes. Subsequently, these billets undergo further processing and transformation into specific construction components through diverse manufacturing techniques. One widespread application of steel billets involves beam production, which is indispensable for supporting the weight of floors, roofs, and walls in buildings. The billets are subjected to rolling mills, where they are heated and passed through a series of rollers to acquire the desired beam profile. This process facilitates the production of beams in varying sizes and lengths, tailored to the unique requirements of each construction project. Steel billets are also employed in the manufacture of columns, which provide vertical support to structures. Similar to beams, billets are processed through rolling mills to achieve the necessary column shape. Subsequently, the columns are connected to the beams, creating the skeletal framework of the building and ensuring strength and stability. Additionally, steel billets find application in the production of reinforcing bars, commonly referred to as rebar, used for reinforcing concrete structures. These rebar play a critical role in enhancing the strength and durability of concrete. Billets are once again processed through rolling mills to create rebar in various diameters and lengths. The rebar is then embedded within the concrete to provide tensile strength, preventing cracking, and increasing the overall structural integrity. In summary, steel billets are pivotal in the production of construction components as they serve as the starting point for the manufacturing process. They are transformed into beams, columns, and rebar, which offer the necessary strength and stability required for building and infrastructure projects.

- Q: What are the different types of steel billet rolling techniques?

- The manufacturing process utilizes various steel billet rolling techniques to shape the steel into desired forms and dimensions. Among the commonly employed techniques are the following: 1. Hot rolling: This technique, widely used, involves heating the steel billet to high temperatures and passing it through a series of rolling mills. By reducing thickness and increasing length, hot rolling achieves the desired shape. 2. Cold rolling: Steel billets are rolled at room temperature in this technique. It yields steel with precise dimensions and a smooth surface finish. It is commonly used for producing steel sheets, strips, and bars. 3. Ring rolling: Seamless steel rings are produced using this technique. The steel billet is heated and then rolled between two rotating rolls that gradually shape the billet into a ring. Bearings, gears, and flanges are commonly produced using ring rolling. 4. Continuous casting and rolling: In this technique, molten steel is continuously cast into billets, which are then directly rolled into desired shapes. It eliminates the need for separate casting and rolling processes, making it a more efficient and cost-effective technique. 5. Cross-rolling: This technique is employed to produce steel billets with non-uniform cross-sections. The billet is rolled between two rolls with different profiles, resulting in a billet of the desired shape. 6. Skew rolling: Skew rolling is specifically used to produce steel balls utilized in various industries like mining and cement production. The steel billet is rolled between two rotating rolls at an angle, creating a helical motion that forms the ball shape. These examples represent only a fraction of the available steel billet rolling techniques. Each technique offers unique advantages and is selected based on the desired final product and manufacturing requirements.

- Q: What are the common defects in billet? What's the cause?

- 4. Tungsten inclusion;Six, arc scratch and heat crack and overlap: 1:Two reheat cracks 3 cracks

Send your message to us

Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords