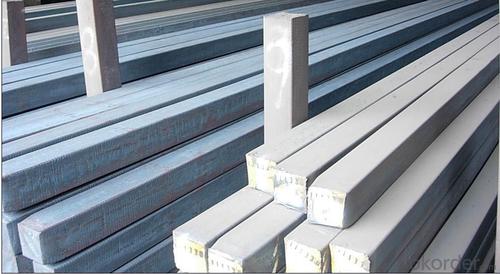

Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel billets contribute to the overall thermal insulation of a structure?

- Steel billets do not contribute to the overall thermal insulation of a structure. In fact, steel is a good conductor of heat and can transfer heat quickly, making it a poor choice for thermal insulation.

- Q: Can steel billets be used for decorative purposes?

- Yes, steel billets can be used for decorative purposes. Steel billets are the raw material used for various applications in the steel industry, including the production of decorative products. By applying various techniques such as forging, casting, or machining, steel billets can be transformed into aesthetically pleasing decorative items such as sculptures, ornamental gates, furniture, architectural elements, and more. The versatility and durability of steel make it a popular choice for decorative purposes, as it can be shaped into intricate designs and withstand outdoor conditions. Additionally, steel can be further enhanced with various finishes, such as painting, powder coating, or patina, to enhance its visual appeal and complement different styles or aesthetics.

- Q: What are the different forging processes for steel billets?

- Different forging processes can be used for steel billets, depending on the desired final product's shape and properties. Some of these processes include: 1. Open-Die Forging: Steel billets are placed between flat dies and compressed to shape them. The billet is not completely enclosed, allowing it to freely deform and flow. Open-die forging is commonly used for large and simple shapes like bars, shafts, and rings. 2. Closed-Die Forging: Also known as impression-die forging, this process involves using specially shaped dies that fully enclose the steel billet. The dies have cavities matching the desired final shape. When the billet is compressed between the dies, it takes the shape of the cavities, resulting in a precise and intricate final product. Closed-die forging is suitable for complex shapes like automotive components, aerospace parts, and tools. 3. Seamless Rolled Ring Forging: Steel billets are shaped into a ring blank and then subjected to intense pressure between two rotating dies. The dies gradually reduce the diameter of the ring blank, elongating and shaping it into the desired ring shape. Seamless rolled ring forging is commonly used for producing large and high-strength rings used in turbines, gears, and bearings. 4. Upset Forging: In this process, the steel billet is heated and placed between two dies. One die remains stationary while the other moves towards the billet, compressing it and causing radial spreading. Upset forging is commonly used for short-length parts like bolts, screws, and rivets. 5. Press Forging: A hydraulic or mechanical press is used to apply compressive forces to the steel billet, shaping it into the desired form. Press forging can be done with open or closed dies, depending on shape complexity. It is commonly used for producing components with high accuracy and intricate details like gears, engine parts, and hand tools. Each of these forging processes has its own advantages and limitations based on the specific requirements of the steel billet and the desired final product. Factors such as shape complexity, material properties, production volume, and cost considerations determine the choice of forging process.

- Q: How do steel billets contribute to the manufacturing of automotive components?

- Steel billets play a crucial role in the manufacturing of automotive components. These billets, which are semi-finished metal pieces, serve as the starting material for the production of various automotive parts. One of the main ways steel billets contribute to automotive component manufacturing is through the process of forging. Forging involves shaping the metal billets under high pressure and temperature, typically using a hammer or a press, to create the desired automotive parts. This process helps in enhancing the strength, durability, and reliability of the components, making them suitable for the demanding conditions of the automotive industry. Steel billets are also used in the production of engine components such as crankshafts, connecting rods, and piston rods. These parts require high strength and resistance to wear and tear, which are achieved by starting with high-quality steel billets. By using steel billets as the raw material, automotive manufacturers can ensure that the resulting components have the necessary mechanical properties to withstand the stresses and forces experienced by the engine during operation. Furthermore, steel billets are employed in the manufacturing of suspension components, such as control arms and stabilizer bars. These components are responsible for maintaining the stability, handling, and comfort of the vehicle. Using steel billets in their production ensures that the suspension components can withstand the heavy loads and impacts encountered on the road, providing a smooth and safe driving experience. Additionally, steel billets contribute to the manufacturing of safety-related automotive components. For instance, they are used in the production of structural components like chassis frames and body reinforcements. These components are essential for protecting the occupants in the event of a collision or impact, and steel billets provide the necessary strength and rigidity to ensure their effectiveness. In conclusion, steel billets are a vital element in the manufacturing of automotive components. They enable the production of strong, durable, and reliable parts, ensuring the overall performance, safety, and longevity of vehicles. By starting with high-quality steel billets, automotive manufacturers can meet the demanding requirements of the industry and deliver high-performance vehicles to consumers.

- Q: How are steel billets used in construction?

- Steel billets are an essential component in the construction industry, playing a crucial role in the development of various structures. These billets are semi-finished steel products that are commonly used as raw materials in the manufacturing of other steel products, including bars, rods, and beams. In construction, steel billets are primarily used in the fabrication of reinforced concrete structures. Reinforced concrete is a widely used building material due to its high strength and durability. Steel billets are used to create steel reinforcement bars, also known as rebar, that are embedded within the concrete to provide additional strength and structural integrity. During construction, steel billets are first heated and then passed through rolling mills to form long, slender rods or bars. These rebar are then cut into desired lengths and placed strategically within the concrete framework. The rebar acts as a reinforcement, allowing the concrete to withstand tensile forces and prevent cracking or failure under heavy loads or external pressures. Steel billets are also used in the construction of steel structures such as bridges, towers, and high-rise buildings. These structures require steel beams and columns for support, and steel billets are often utilized to manufacture these components. By using steel billets, construction companies can ensure the strength, stability, and longevity of these structures. Additionally, steel billets find applications in the construction of smaller-scale infrastructure such as roads, pipelines, and tunnels. The high strength and durability of steel make it an ideal material for these projects, and steel billets provide the necessary foundation for producing the required steel products. In summary, steel billets are an integral part of construction, serving as the raw material for manufacturing various steel products used in reinforced concrete structures and steel infrastructure. Their use ensures the strength, stability, and longevity of buildings and other construction projects, making them an essential component in the construction industry.

- Q: How are steel billets used in the manufacturing of electrical appliances?

- Steel billets are essential for the manufacturing process of electrical appliances, serving as semi-finished steel products in a rectangular shape. They are used as raw materials for various components of electrical appliances. One primary application of steel billets in electrical appliance manufacturing is in producing motor cores. Motor cores are crucial parts of electric motors found in appliances like refrigerators, washing machines, and air conditioners. The steel billets are processed and shaped into laminated cores, which are then stacked together to form the motor core. These cores provide the necessary structural support and magnetic properties for generating rotational motion. In addition, steel billets are also used in manufacturing electrical wires and cables, which are vital for transmitting electricity within appliances. The billets are processed and drawn into thin wires, which are then insulated and bundled to create the required electrical connections within the appliances. Furthermore, steel billets are utilized in making housings and frames for electrical appliances. These components offer structural support and protection for the internal electrical parts. The billets are processed and molded into various shapes and sizes to create durable and rigid housings capable of withstanding everyday stress and environmental conditions. Overall, steel billets play a crucial role in the manufacturing of electrical appliances, providing the necessary raw materials for motor cores, electrical wires, cables, and housing components. Their strength, durability, and magnetic properties make them an ideal choice for ensuring the quality and performance of electrical appliances.

- Q: How are steel billets used in the manufacturing of industrial compressors?

- Industrial compressors require steel billets as a crucial part of their manufacturing process. These billets, essentially semi-finished steel products in the shape of a rectangular solid, are the starting material for making different compressor components. To begin with, steel billets are heated to high temperatures and then passed through rolling mills to shape them into specific forms like bars, rods, or sheets. These processed steel billets are then used to fabricate important compressor components such as the crankshaft, connecting rods, cylinder blocks, and piston rings. The crankshaft, which converts the piston's reciprocating motion into rotational motion, is typically forged from a steel billet. The billet undergoes controlled heating, shaping, and machining processes to achieve the desired shape and strength necessary to withstand the high pressures and forces within the compressor. Likewise, connecting rods, responsible for connecting the piston to the crankshaft, are also made from steel billets. These billets are machined precisely and undergo various heat treatment processes to ensure optimal strength and durability. Cylinder blocks, the primary structural frame of the compressor, are often casted from steel billets. The billets are melted and poured into molds to achieve the desired shape. Once solidified, further machining is performed on the cylinder block to create the cylinder bores, mounting surfaces, and other necessary features. Moreover, steel billets are utilized for producing piston rings, which play a crucial role in maintaining proper compression and preventing leakage. The billets are machined and then subjected to heat treatment processes to enhance wear resistance and ensure a precise fit within the cylinder. In summary, steel billets are indispensable in the manufacturing of industrial compressors as they provide the raw material for creating vital components. The ability to shape and process steel billets enables the production of robust, durable, and high-performance compressors capable of meeting the demanding requirements of various industries.

- Q: What are the different types of steel billet rolling defects?

- There are several types of steel billet rolling defects that can occur during the rolling process. These defects can negatively impact the quality and integrity of the finished product. Some of the most common types of steel billet rolling defects include: 1. Surface cracks: These are small cracks that appear on the surface of the billet. They can occur due to improper cooling or excessive rolling pressure. Surface cracks can compromise the strength and durability of the steel. 2. Center cracks: Center cracks occur in the inner core of the billet. They are usually caused by improper temperature control during the rolling process. Center cracks can lead to structural weaknesses and reduced performance of the steel. 3. Scalloping: Scalloping refers to the formation of shallow depressions or grooves on the surface of the billet. It usually occurs due to uneven or improper rolling pressure distribution. Scalloping can affect the appearance and surface quality of the steel. 4. Lamination: Lamination defects involve the separation of layers within the billet. They can occur due to the presence of impurities or inclusions in the steel, as well as improper heating or rolling conditions. Lamination defects can weaken the steel and increase the risk of failure. 5. Wavy edges: Wavy edges occur when the edges of the billet become uneven or distorted during the rolling process. This can be caused by improper alignment or uneven pressure distribution. Wavy edges can affect the dimensional accuracy and overall quality of the steel. 6. Surface defects: Surface defects include scratches, pits, or other imperfections on the surface of the billet. They can occur due to inadequate cleaning or handling procedures, as well as improper rolling conditions. Surface defects can impact the appearance and surface quality of the steel. Overall, these steel billet rolling defects can have significant implications for the quality, performance, and safety of the finished product. It is important for manufacturers to closely monitor the rolling process and implement proper quality control measures to minimize the occurrence of these defects.

- Q: How do steel billets come out?

- Three, steel rolling:Rolling steel or continuous casting billet into various steels by rolling mill

- Q: What are the different surface finishes available for steel billets?

- There are several surface finishes available for steel billets, including mill finish, hot rolled pickled and oiled (HRPO), cold rolled, galvanized, and coated finishes. These finishes enhance the appearance, protect against corrosion, improve surface smoothness, and provide specific properties required for different applications.

Send your message to us

Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords