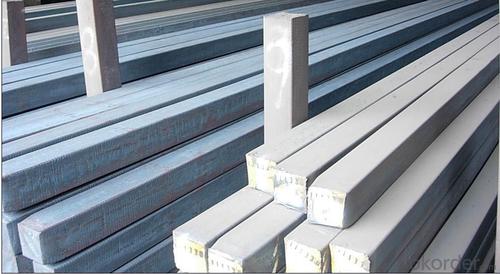

Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel billets contribute to the manufacturing of marine gear?

- Steel billets play a crucial role in the manufacturing of marine gear due to their unique characteristics and properties. Marine gear includes various components such as propeller shafts, gears, and bearings, which require high strength and resistance to corrosion and wear. Steel billets, which are semi-finished metal forms, serve as the starting material for the manufacturing process. They are typically made from carbon or alloy steel and are shaped into long, rectangular bars. These billets are then further processed to create the specific marine gear components. The high strength of steel billets makes them ideal for marine gear manufacturing as they can withstand the heavy loads and intense pressures experienced in marine environments. This strength ensures the durability and reliability of the gear components, preventing failures and enhancing safety. Corrosion resistance is another critical factor in marine gear manufacturing. Steel billets can be made from stainless steel, which contains chromium and other alloying elements that form a protective layer on the surface, preventing rust and corrosion caused by exposure to saltwater. This corrosion resistance is vital for marine gear as it ensures the longevity and performance of the components in harsh marine conditions. Furthermore, steel billets can be heat-treated to improve their mechanical properties, such as hardness, toughness, and wear resistance. This heat treatment process involves heating the billets to specific temperatures and then cooling them rapidly or slowly, depending on the desired properties. Heat-treated steel billets provide the necessary hardness and wear resistance required for gears, shafts, and bearings to withstand the constant friction and stress encountered in marine applications. In conclusion, steel billets contribute significantly to the manufacturing of marine gear by providing the required strength, corrosion resistance, and mechanical properties. They serve as the foundation material for creating durable and reliable components that can withstand the challenging conditions of the marine environment.

- Q: What are the different production methods for steel billets?

- There are several different production methods for steel billets, each with its own unique characteristics and advantages. 1. Casting: One of the most common methods is the casting process, where molten steel is poured into a mold and allowed to solidify. This method can be further divided into continuous casting and ingot casting. Continuous casting involves the continuous pouring of molten steel into a water-cooled mold, which results in a continuous solidification process. Ingot casting, on the other hand, involves pouring molten steel into individual molds to create ingots that are then used as raw material for further processing. 2. Direct Reduction: Another method is the direct reduction process, which involves the reduction of iron ore in the presence of a reducing agent such as natural gas or coal. This process produces direct reduced iron (DRI), which can then be used to produce steel billets through subsequent melting and casting processes. 3. Electric Arc Furnace (EAF): The EAF method involves melting scrap steel in an electric arc furnace. This process is commonly used in recycling steel as it allows for the use of various scrap sources, including old cars, appliances, and industrial waste. The molten steel is then cast into billets or other desired shapes. 4. Basic Oxygen Furnace (BOF): The BOF method is a traditional steelmaking process that involves the conversion of molten iron from a blast furnace into steel through the injection of oxygen. This process is used for large-scale production of steel billets and offers high efficiency and flexibility in terms of raw material usage. 5. Powder Metallurgy: Powder metallurgy is an alternative method that involves compacting and sintering metal powders to create solid objects. In the case of steel billets, metal powders are compressed into the desired shape and then heated to a high temperature to achieve solidification. Each of these production methods has its own advantages and is suited for different applications and production scales. The choice of method depends on various factors including the desired properties of the steel, cost considerations, environmental impact, and availability of raw materials.

- Q: What are the different types of shearing machines used for steel billets?

- There are several types of shearing machines commonly used for cutting steel billets. These machines are designed to provide precise and efficient cutting operations in the steel industry. Here are some of the different types of shearing machines used for steel billets: 1. Guillotine Shears: Guillotine shears are one of the most widely used shearing machines for cutting steel billets. They feature a stationary bed and a moving blade that moves vertically to cut through the material. Guillotine shears offer high cutting accuracy and are capable of cutting thick billets with ease. 2. Flying Shears: Flying shears, also known as rotary shears, are another popular type of shearing machine used for cutting steel billets. These machines have a rotating circular blade that cuts through the billet as it moves along the conveyor. Flying shears are known for their high cutting speed and can handle large volumes of billets. 3. Cold Shears: Cold shears are specifically designed for cutting steel billets at lower temperatures to prevent any heat damage to the material. These shearing machines use a hydraulic or mechanical system to apply force and cut through the billet. Cold shears are commonly used in industries where the steel billets need to be cooled down before further processing. 4. Rotary Shears: Rotary shears are typically used for cutting steel billets into smaller sections. These machines feature multiple blades mounted on a rotating drum, which cuts the billet into desired lengths. Rotary shears offer high cutting efficiency and are often used in industries where small-sized billets are required. 5. Hydraulic Shears: Hydraulic shears are versatile shearing machines that can be used for cutting various materials, including steel billets. These machines use hydraulic power to provide the necessary force for cutting through the billet. Hydraulic shears offer high cutting speed and can handle large-sized billets efficiently. Each type of shearing machine mentioned above has its own advantages and is suitable for specific applications in the steel industry. The choice of shearing machine depends on factors such as the size and thickness of the billet, required cutting accuracy, production volume, and other specific requirements of the steel processing operation.

- Q: What are the different surface defects in steel billets?

- Steel billets can have various types of surface defects, which can occur during manufacturing or due to handling and transportation. Some common defects include scale, cracks, lamination, pitting, slivers, rolled-in scale, and surface scratches. Scale forms as a rough, flaky coating during heating and rolling, affecting the billet's appearance. Cracks can be caused by improper cooling, excessive pressure, or stress during handling, compromising the billet's strength. Lamination defects occur when non-metallic layers weaken the billet. Pitting is the formation of small cavities due to corrosion or exposure to corrosive environments. Slivers are thin, protruding pieces caused by improper cutting or shearing. Rolled-in scale refers to embedded scale, requiring additional cleaning. Surface scratches are shallow marks that can affect aesthetics and may need further treatment. Proper identification, handling, and treatment of these defects are essential to ensure the quality of the steel billets. Regular inspection and appropriate techniques can minimize defects and enhance the billets' overall quality.

- Q: What are the applications of steel billets?

- Steel billets are primarily used as raw material in the production of various steel products such as bars, rods, wire, and seamless tubes. They are also used in the manufacturing of components for automotive, construction, and machinery industries. Additionally, steel billets can be further processed to produce forgings, which are used in heavy machinery and equipment.

- Q: What are the main factors affecting the surface finish of steel billets?

- Several key factors can be attributed to the surface finish of steel billets. Firstly, the quality and cleanliness of the raw materials used in the steelmaking process play a significant role. Surface defects and imperfections can occur if there are impurities or contaminants in the raw materials. Secondly, the manufacturing process's processing parameters directly impact the surface finish. Factors like temperature, speed, and pressure can affect the formation of scale, oxidation, and other surface abnormalities. Excessive scaling can result from high temperatures, while inadequate scale removal can occur due to insufficient temperature control. Furthermore, the surface finish of steel billets is influenced by the type and condition of the equipment used for production. Abrasions, scratches, or other defects in the machinery can transfer onto the billets, affecting their surface quality. Regular maintenance and proper upkeep of the machinery are crucial to ensure a smooth and defect-free surface finish. Moreover, the choice and application of lubricants and coatings during the production process also impact the surface finish. These substances protect the billets from oxidation and reduce friction. However, incorrect application or the use of the wrong lubricant can lead to uneven coating, streaking, or other surface irregularities. Lastly, the handling and storage of steel billets after production can affect their surface finish. Mishandling, improper storage conditions, or exposure to moisture, chemicals, or contaminants can all contribute to surface defects and deterioration. In conclusion, the surface finish of steel billets is influenced by the quality of raw materials, processing parameters, equipment condition, lubricant and coating application, and proper handling and storage. By closely monitoring and optimizing these factors, manufacturers can achieve a high-quality surface finish that meets the desired specifications and requirements.

- Q: What are the different types of straightening methods used for steel billets?

- There are several different types of straightening methods used for steel billets, depending on the specific requirements and desired outcome. These methods include: 1. Roller Straightening: This method involves passing the steel billets through a series of rollers that apply pressure in various directions to straighten them. The rollers can be adjusted to apply more pressure on certain areas of the billet that may be bent or twisted. 2. Hydraulic Straightening: In this method, hydraulic presses are used to apply pressure on the billets, either in a single direction or in multiple directions. The pressure can be adjusted to achieve the desired level of straightness. 3. Heat Straightening: Heat straightening is a method that involves applying heat to the bent or twisted areas of the steel billets and then using hydraulic or mechanical tools to straighten them. The heat softens the steel, allowing it to be reshaped more easily. 4. Hammering: Hammering is a traditional method of straightening steel billets, where skilled workers use hammers and anvils to manually reshape the billets. This method requires a high level of skill and precision to achieve the desired straightness. 5. Magnetic Straightening: Magnetic straightening is a non-contact method that uses magnetic fields to apply forces on the steel billets and straighten them. This method is often used for smaller and thinner billets, where other methods may cause damage or distortion. Each of these straightening methods has its own advantages and limitations, and the choice of method depends on factors such as the size and thickness of the billets, the degree of straightness required, and the available equipment and resources.

- Q: How are steel billets used in the production of industrial valves?

- Steel billets are used in the production of industrial valves as they serve as the raw material for shaping and forming various valve components, such as bodies, bonnets, stems, and discs. Through machining, forging, and welding processes, the steel billets are transformed into the required shapes and sizes, ensuring the strength and durability of the valves.

- Q: How are steel billets rolled or forged into other shapes?

- Steel billets can be rolled into other shapes through a process called hot rolling, where the billet is heated and passed through a series of rollers that apply pressure to shape it into the desired form. Alternatively, forging involves applying compressive forces to the heated billet, either manually or by using a machine, to reshape it into the desired shape.

- Q: What are the different surface defects found in alloy steel billets?

- There are several different surface defects that can be found in alloy steel billets. These defects can occur during the production process and can have an impact on the quality and performance of the final product. Some of the common surface defects found in alloy steel billets include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of the billet during the heating and cooling process. It can be caused by exposure to air or by the presence of impurities in the steel. Scale can negatively affect the surface finish and can also lead to corrosion. 2. Cracks: Cracks can occur on the surface of the billet due to various reasons such as improper cooling, excessive stress, or improper handling. These cracks can weaken the structural integrity of the billet and can lead to failure during subsequent processing or in the final product. 3. Pits: Pits are small depressions or cavities that can be found on the surface of the billet. They can be caused by the presence of impurities or by the reaction of the steel with the environment. Pits can affect the surface finish and can also act as stress concentration points, leading to further damage or failure. 4. Laminations: Laminations are layers or sheets of non-metallic material that can be found within the billet. They can occur due to incomplete bonding during the production process or due to the presence of impurities in the steel. Laminations can weaken the billet and can lead to failure under load. 5. Inclusions: Inclusions are non-metallic particles or impurities that can be found within the steel. They can be introduced during the production process or can be present in the raw materials. Inclusions can affect the mechanical properties of the steel and can lead to reduced strength, toughness, and ductility. 6. Decarburization: Decarburization is the loss of carbon from the surface of the steel. It can occur during the heating process or due to exposure to air. Decarburization can result in reduced hardness and strength in the affected area. It is important to detect and address these surface defects in alloy steel billets to ensure the production of high-quality and reliable products. Various inspection and testing methods, such as visual inspection, ultrasonic testing, and magnetic particle inspection, can be employed to identify and assess these defects.

Send your message to us

Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords