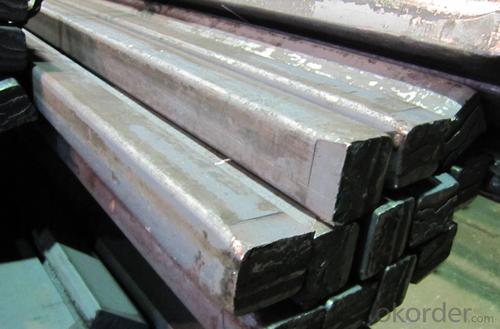

Q235/3SP 135MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 135MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 135MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 135MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 135MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different quality control measures for steel billets?

- To ensure the high quality of steel billets, several quality control measures are implemented during their production and inspection. These measures encompass: 1. Thoroughly analyzing the chemical composition of steel billets to ensure it aligns with the required specifications. This analysis involves determining the content of elements like carbon, manganese, sulfur, phosphorus, and others. Any deviations from the specified composition can impact the mechanical properties of the billets. 2. Verifying the size, shape, and weight of steel billets through dimensional inspection. This entails measuring the length, width, and thickness of the billets using precision instruments and ensuring they meet the specified tolerances. Any deviations from the required dimensions can affect the billets' performance during subsequent processing. 3. Inspecting the surface of steel billets for defects or irregularities. This includes checking for cracks, surface discontinuities, surface roughness, and other imperfections. Surface inspection is typically conducted using visual inspection techniques or non-destructive testing methods like magnetic particle testing or ultrasonic testing. 4. Conducting mechanical testing to assess the mechanical properties of steel billets. This involves tests such as tensile testing, hardness testing, and impact testing to determine the billets' strength, ductility, toughness, and other mechanical characteristics. These tests ensure that the billets possess the required mechanical properties for their intended applications. 5. Examining the microstructure of steel billets through metallurgical examination. This helps identify any defects in the metal structure, such as grain size, segregation, inclusions, or improper heat treatment. By assessing the metallurgical properties, the quality control team can ensure that the billets are free from any internal defects that might compromise their structural integrity. 6. Using non-destructive testing techniques like ultrasonic testing, magnetic particle testing, or eddy current testing to detect internal defects or discontinuities that may not be visible through visual inspection. These methods allow for the detection of flaws without damaging the billets, ensuring their integrity is maintained. 7. Maintaining proper documentation and traceability throughout the production process. This involves documenting the results of all inspections, tests, and analyses performed on the steel billets, as well as tracking their origin, processing history, and any relevant certifications. This documentation ensures transparency and enables traceability in case of any quality-related issues. By implementing these quality control measures, steel manufacturers can ensure that the produced billets meet the required specifications, possess the desired properties, and are of high quality. This enhances their reliability and suitability for various applications in industries such as construction, automotive, and manufacturing.

- Q: Are steel billets used in the production of household goods?

- No, steel billets are not typically used in the production of household goods. Steel billets are semi-finished products that are used as raw material for various industries, such as construction, automotive, and manufacturing. They are usually hot-rolled into different shapes, such as bars, rods, or sheets, which are then further processed to create the desired household goods. For household goods, manufacturers often use specific types of steel, such as stainless steel or carbon steel, that have been processed and shaped according to the particular product requirements.

- Q: What are the different types of steel billet shearing machines?

- There are several different types of steel billet shearing machines, including hydraulic shearing machines, mechanical shearing machines, and pneumatic shearing machines.

- Q: What is the typical density of a steel billet?

- The typical density of a steel billet is approximately 7.8 grams per cubic centimeter (g/cm³).

- Q: Can steel billets be used for structural applications?

- Yes, steel billets can be used for structural applications. Steel billets are semi-finished products commonly used in the manufacturing of various structural components such as beams, columns, and rods. These billets can be further processed through rolling or forging to create the desired shapes and sizes required for structural applications. The high strength and durability of steel make it a popular choice for constructing buildings, bridges, and other infrastructure projects.

- Q: How are steel billets used in the production of transmission towers?

- Steel billets are used in the production of transmission towers as the raw material for manufacturing tower sections. These billets are cut, shaped, and welded to create the structural components of the towers, ensuring strength, stability, and durability in supporting electrical transmission lines.

- Q: What is the average price of steel billets?

- The average price of steel billets can vary depending on various factors such as the current market conditions, supply and demand dynamics, and the specific grade and quality of the steel billets. It is important to note that steel billet prices are influenced by global economic factors, including raw material costs, energy prices, and trade policies, which can lead to fluctuations in the average price. To get an accurate understanding of the average price of steel billets, it is recommended to refer to industry reports, trade publications, and market analysis platforms that provide up-to-date information on steel prices. Additionally, consulting with steel suppliers and manufacturers or engaging in negotiations with multiple sources can help determine the prevailing average price in a specific region or market.

- Q: How are steel billets used in the production of mining machinery?

- Steel billets are used in the production of mining machinery as they serve as the raw material for forging and shaping various components such as gears, shafts, frames, and structural elements. These billets are heated and then formed into desired shapes through processes like rolling, machining, and welding. The high strength and durability of steel make it ideal for withstanding the harsh conditions and heavy loads associated with mining operations, ensuring the reliability and performance of mining machinery.

- Q: What is the role of steel billets in the construction industry?

- Steel billets play a crucial role in the construction industry as they serve as the raw material for manufacturing various steel products. These solid, semi-finished forms of steel are typically used in the production of beams, bars, rods, and other structural components. By providing strength, durability, and flexibility to structures, steel billets contribute significantly to the overall integrity and safety of buildings, bridges, and other infrastructure projects.

- Q: What are the different types of casting processes used for shaping steel billets?

- Steel billets can be shaped using various casting processes. These methods include: 1. Continuous Casting: The most commonly used technique involves pouring molten steel into a continuously moving, water-cooled mold. The solidifying steel is continuously pulled out of the mold, resulting in a seamless billet. This process is efficient and allows for high production rates. 2. Centrifugal Casting: This method utilizes a rotating mold into which molten steel is poured. The centrifugal force evenly distributes the metal along the mold walls, creating a cylindrical billet. Centrifugal casting is known for producing high-quality, defect-free billets. 3. Ingot Casting: A traditional approach where molten steel is poured into a mold and left to solidify. The resulting solid steel, called an ingot, is then processed further to achieve the desired billet shape. Ingot casting offers flexibility in terms of billet size and shape. 4. Sand Casting: This process is suitable for manufacturing large and complex steel billets. It involves creating a mold using a mixture of sand and a binder. Molten steel is poured into the mold, and once it solidifies, the mold is removed to reveal the billet. While sand casting allows for custom-shaped billets, it is a slower and less precise method compared to others. 5. Investment Casting: Also known as lost-wax casting, this technique is ideal for intricate and complex billet shapes. Investment casting begins with the creation of a wax pattern in the desired shape. The wax pattern is then coated with a ceramic shell, and the wax is melted away, leaving behind a hollow mold. Molten steel is poured into the mold and solidifies, after which the ceramic shell is broken to retrieve the billet. Each casting process has its own advantages and disadvantages, and the choice depends on factors such as desired billet shape, size, production volume, and quality requirements.

Send your message to us

Q235/3SP 135MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords