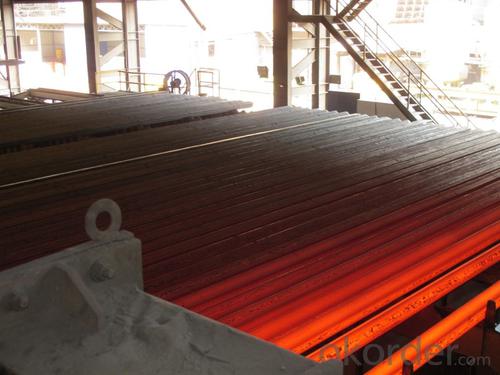

Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different surface treatments for improved wear resistance in steel billets?

- Steel billets can be subjected to various surface treatments to enhance their wear resistance. These treatments aim to increase the durability and longevity of the steel, making it more resilient against wear and tear. One widely utilized surface treatment method is case hardening. This technique involves heating the steel billets to high temperatures and then rapidly cooling them in a quenching medium, like oil or water. This process results in the formation of a tough outer layer, known as a case, while maintaining a comparatively softer core. The hardened case provides exceptional wear resistance, while the softer core retains toughness and ductility. Nitriding is another surface treatment option for improved wear resistance. This process entails introducing nitrogen into the surface of the steel billets, typically through a gas or plasma-based approach. The nitrogen permeates the steel and forms a hard layer of nitride on the surface. This nitride layer significantly enhances the hardness and wear resistance of the steel, making it suitable for applications requiring high wear resistance. Hard chrome plating is a third surface treatment technique. It involves electroplating a layer of chromium onto the surface of the steel billets. The chromium layer offers excellent wear and corrosion resistance, making it ideal for applications where the steel will be exposed to harsh environments or abrasive substances. Furthermore, advanced surface treatment methods such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) can be employed to enhance the wear resistance of steel billets. These processes involve depositing a thin film of a wear-resistant material, like titanium nitride or diamond-like carbon, onto the steel's surface. These thin films create a hard and low-friction surface, improving wear resistance and reducing frictional losses. In summary, these surface treatments present a diverse range of options to improve the wear resistance of steel billets. The choice of treatment depends on factors such as the specific application requirements, desired level of wear resistance, and budget constraints. Seeking guidance from materials experts or surface treatment specialists can aid in determining the most suitable treatment for a particular steel billet application.

- Q: Can steel billets be coated for improved corrosion resistance?

- Yes, steel billets can be coated with various materials such as zinc, aluminum, or polymer coatings to enhance their corrosion resistance.

- Q: How are steel billets used in the production of railway components?

- Steel billets are used in the production of railway components by being heated and molded into specific shapes, such as rails, sleepers, and fasteners. These billets serve as the raw material that is further processed and refined to create durable and strong components that can withstand the heavy loads and stresses of railway operations.

- Q: How are steel billets used in the production of valves?

- Steel billets are an integral component in the production of valves as they serve as the raw material for manufacturing valve bodies. Valve bodies are the main structural component of valves, providing the necessary strength and durability to withstand the high pressures and temperatures they are subjected to in various applications. To produce valve bodies, steel billets undergo several manufacturing processes. Initially, the billets are heated and then passed through a series of rollers to shape them into the desired form, typically a cylindrical or rectangular shape. This process, known as hot rolling, enhances the mechanical properties of the steel, making it more suitable for valve applications. After the hot rolling process, the steel billets are further processed through forging or machining operations to refine their shape and dimensions. Forging involves applying compressive forces to the heated billets, reshaping them into the final valve body form. On the other hand, machining involves removing excess material through cutting, drilling, and shaping to achieve the desired dimensions and surface finish. Once the valve bodies are formed, further processes such as drilling, threading, and finishing are carried out to create the necessary openings, connections, and surface smoothness required for the valve's functionality. These processes may involve using specialized machinery and tools to ensure precise and accurate dimensions. Overall, steel billets are crucial in the production of valves as they serve as the starting point for creating the valve bodies. The properties of steel, combined with the various manufacturing processes, enable the production of high-quality valves that can effectively control the flow of fluids or gases in various industrial applications.

- Q: How are steel billets cast into shape?

- The process of continuous casting is used to shape steel billets. In this process, molten steel is poured into a copper mold that is cooled by water. The mold is in the shape of a billet, and as the steel is poured, it starts to solidify along the mold's walls. To ensure complete solidification, a water spray is employed at the bottom of the mold, rapidly cooling the steel. As the steel solidifies, it is continuously pulled out of the mold either by a set of rollers or a chain conveyor. Once the billet has solidified entirely, it is cut into desired lengths using a high-speed torch or saw. These cut billets are then transported to the next stage of the steel manufacturing process, such as rolling or forging, where they are further shaped into the final product. Continuous casting enables the production of steel billets with consistent cross-sectional shapes and sizes. This efficient process generates high-quality steel products while minimizing waste.

- Q: What is the role of steel billets in the manufacturing of wind turbines?

- Steel billets play a crucial role in the manufacturing of wind turbines as they are used as the raw material for producing various components of the turbine, such as tower sections, base frames, and rotor hubs. The high strength and durability of steel make it an ideal choice for withstanding the demanding operating conditions of wind turbines, including strong winds and extreme weather. The billets are melted, cast, and then further processed to create these components, ensuring the structural integrity and longevity of the turbines.

- Q: How are steel billets used in the production of automotive frames?

- Steel billets are used in the production of automotive frames as a primary raw material. Billets are essentially long, rectangular-shaped pieces of steel that are heated and then formed into specific shapes through various manufacturing processes. In the case of automotive frames, these billets are typically heated and then passed through a series of dies and rollers to form the desired shape and dimensions. Once the billets are formed into the appropriate shape, they are further processed through cutting, bending, and welding techniques to create the intricate and sturdy structure of an automotive frame. The use of steel billets in the production of automotive frames is preferred due to the high strength and durability properties of steel, which are crucial for ensuring the safety and structural integrity of the vehicles. Moreover, steel billets offer excellent formability and machinability, allowing manufacturers to create complex frame designs that meet the specific requirements of different vehicle models. Additionally, steel is a cost-effective material, making it a popular choice for mass production in the automotive industry. Overall, steel billets play a vital role in the production of automotive frames by providing a strong and reliable foundation for the vehicle's structure. The use of these raw materials, along with advanced manufacturing techniques, ensures that automotive frames are able to withstand various forces and impacts, ultimately contributing to the overall safety and performance of the vehicles.

- Q: How do steel billets contribute to the manufacturing of sports equipment?

- Steel billets contribute to the manufacturing of sports equipment in various ways. Firstly, steel billets are the raw material used to produce steel bars and rods, which are then used to create the frame and structure of sports equipment such as golf clubs, tennis rackets, and hockey sticks. The strength and durability of steel make it an ideal material for these applications, as it can withstand the high impact forces and stresses that occur during sports activities. Additionally, steel billets are also used to manufacture components of sports equipment such as weights, dumbbells, and barbells. These components require a high density material that can handle heavy loads, and steel provides the necessary strength and stability. Furthermore, steel billets are used in the production of sports equipment accessories like ball bearings, springs, and fasteners. These small yet crucial components play a vital role in the overall performance and functionality of sports equipment. Steel's excellent corrosion resistance and ability to withstand extreme conditions make it a preferred choice, ensuring long-lasting and reliable performance. Moreover, steel billets contribute to the manufacturing of sports equipment by enabling the production of high-quality and precision-made parts. Steel's malleability and formability allow it to be shaped into various complex designs and configurations, ensuring that sports equipment meets the specific requirements of athletes and performs optimally. In summary, steel billets are an indispensable component in the manufacturing of sports equipment. Their strength, durability, versatility, and formability make them an ideal material for producing frames, components, and accessories that enhance the performance and longevity of sports equipment.

- Q: How are steel billets used in the production of shipbuilding materials?

- Steel billets are used in the production of shipbuilding materials as they serve as the primary raw material for shaping and forming various components such as hulls, frames, and beams. These billets are heated and then shaped through processes like rolling or forging to create the desired shapes and sizes required for ship construction. The high strength and durability of steel make it an ideal material for shipbuilding, ensuring the structural integrity and safety of the vessels.

- Q: What are the different types of steel billet casting defects?

- During the casting process of steel billets, various types of defects may occur, impacting the final product's quality and performance. These defects can range in severity and have different effects on the billets. Common defects include: 1. Insufficient feeding of liquid metal during solidification can cause shrinkage defects, resulting in voids or cavities within the billet. This weakens the billet's strength and may lead to failure under stress. 2. Porosity defects are characterized by the presence of small gas bubbles or voids within the billet. They reduce density, weaken the material, and affect mechanical properties such as tensile strength and ductility. 3. Foreign substances, such as non-metallic particles, oxides, or impurities, can become trapped within the billet, resulting in inclusion defects. These negatively impact mechanical properties like ductility and increase brittleness. 4. Surface defects, like cracks, scabs, or uneven surfaces, can occur during casting, affecting the appearance and structural integrity of the billet. 5. Uneven distribution of alloying elements within the billet leads to segregation defects. This inconsistency in composition affects mechanical properties and overall performance. 6. During solidification, thermal stresses can cause cracks known as hot tears, weakening the billet and reducing its strength under stress. 7. When the liquid metal fails to completely fill the mold cavity, misruns occur, resulting in incomplete billets. This defect leads to reduced dimensions, poor surface finish, and compromised mechanical properties. Addressing and identifying these defects is crucial to ensure the production of high-quality and reliable steel products. Techniques such as proper mold design, controlling casting parameters, and process optimization can be employed to minimize these defects and improve the overall quality of the billet.

Send your message to us

Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords