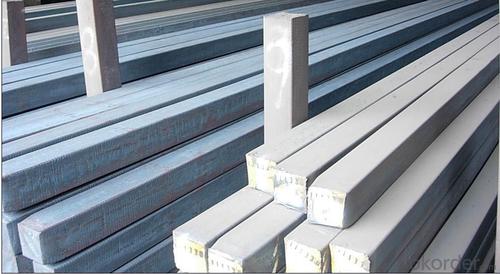

Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the potential applications of steel billets in the medical industry?

- Steel billets have several potential applications in the medical industry. They can be used for the manufacturing of medical instruments, such as surgical tools, implants, and prosthetics, due to their strength, durability, and corrosion resistance. Steel billets can also be utilized in the production of medical equipment and machinery, such as MRI machines and X-ray tables, as they provide structural support and stability. Additionally, steel billets can be used for the fabrication of medical furniture and fixtures, like hospital beds and surgical tables, ensuring reliability and long-lasting performance in healthcare settings.

- Q: What are the potential applications of steel billets in the chemical aftermarket?

- Steel billets have several potential applications in the chemical aftermarket. They can be used as raw material for the production of various chemical products, such as pipes, tanks, and containers. Additionally, steel billets can be utilized in the construction of chemical processing equipment, such as reactors and heat exchangers, due to their strength and durability. Furthermore, they can also serve as a base material for the fabrication of specialty alloys used in the chemical industry. Overall, steel billets play a crucial role in supporting the production and infrastructure needs of the chemical aftermarket.

- Q: What are the potential applications of steel billets in the agricultural aftermarket?

- Steel billets have a wide range of potential applications in the agricultural aftermarket. One of the key uses of steel billets in this industry is for the manufacturing of agricultural machinery and equipment. Steel billets are commonly used to fabricate components such as plows, cultivators, seeders, and harvesting equipment. The agricultural industry requires durable and robust machinery that can withstand the harsh conditions of farming operations. Steel billets provide the necessary strength and toughness to withstand the demanding tasks involved in agriculture, such as tilling the soil or harvesting crops. The high-strength properties of steel billets make them ideal for withstanding heavy loads and rough terrain. Additionally, steel billets can be used for constructing storage and handling structures in the agricultural sector. Steel buildings and structures are highly resistant to weathering, pests, and fire, making them suitable for storing grain, livestock, and other agricultural products. Steel billets can be used to fabricate the main framework of these structures, ensuring their durability and longevity. Another potential application of steel billets in the agricultural aftermarket is for the production of fencing and livestock handling equipment. Steel fencing is commonly used in agricultural settings to secure boundaries, contain livestock, and protect crops from animals. Steel billets can be shaped and welded to create strong and reliable fencing materials that can withstand the test of time. Furthermore, steel billets can be utilized in the manufacturing of irrigation systems and water management equipment. Agricultural operations often require efficient irrigation systems to ensure proper water distribution to crops. Steel billets can be used to fabricate pipes, valves, and other components that are critical for irrigation systems, providing a durable and long-lasting solution. In summary, steel billets have numerous potential applications in the agricultural aftermarket. From manufacturing machinery and equipment to constructing storage structures, fencing, and irrigation systems, steel billets offer the strength, durability, and reliability required in the demanding agricultural industry.

- Q: What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet can vary depending on its intended use and the specific manufacturing process. However, in general, steel billets are rectangular in shape and have dimensions that range from 100mm to 300mm in width, 100mm to 400mm in height, and 6m to 12m in length. These dimensions allow for ease of handling and transportation, as well as flexibility in shaping and forming the steel billet into various end products such as bars, rods, or sheets. It is important to note that these dimensions are not fixed and can be customized based on the specific requirements of the production process or the customer's needs.

- Q: How does the quality of steel billets affect the quality of the final product?

- Determining the quality of the final steel product heavily relies on the quality of steel billets. Steel billets are semi-finished products that undergo a continuous casting process to serve as raw materials for downstream steel products. To begin with, the chemical composition of steel billets greatly affects the quality of the end product. Steel is primarily an alloy of iron and carbon, with additional elements like manganese, chromium, nickel, and others. The presence and precise amount of these alloying elements in the billets have a significant impact on the properties of the final steel, including strength, hardness, ductility, and corrosion resistance. Any variation or deviation in the chemical composition of the billets can lead to undesired changes in the characteristics of the final product. Furthermore, the physical properties of steel billets, including their size, shape, and internal structure, directly influence the quality of the final steel product. The dimensions and geometry of the end product are determined by the size and shape of the billets, ensuring proper fit and functionality. Moreover, the absence of defects like cracks, voids, or inclusions in the internal structure of the billets is crucial for producing high-quality steel products. Imperfections in the billets can propagate and cause failures, compromising the strength and overall quality of the final product. Additionally, the quality of the final steel product is influenced by the manufacturing process of the steel billets. Factors such as cooling rate, casting speed, and temperature control during the continuous casting process can affect the microstructure and overall homogeneity of the billets. Proper control and optimization of the process are necessary to ensure that the billets possess the desired metallurgical properties, such as a uniform grain structure and the absence of segregation or impurities. Moreover, the quality of steel billets directly impacts the efficiency and cost-effectiveness of subsequent steel processing operations. High dimensional accuracy in the billets reduces the need for excessive material removal during machining or shaping processes, resulting in higher material yield, reduced waste, and improved overall productivity. In conclusion, the quality of steel billets significantly influences the quality of the final steel product. The chemical composition, physical properties, and manufacturing process of the billets all play vital roles in determining the characteristics of the end product. By ensuring high-quality steel billets, manufacturers can produce steel products that meet industry standards, possess desired mechanical properties, and exhibit superior performance in various applications.

- Q: How do steel billets contribute to the overall recyclability of a structure?

- The overall recyclability of a structure is greatly enhanced by steel billets, which play a vital role. These semi-finished steel products are created by melting iron ore and other raw materials in a blast furnace. Steel billets possess various characteristics that contribute to a structure's recyclability, thanks to their composition and manufacturing process. Foremost, steel is one of the most recycled materials worldwide. Steel billets can be recycled endlessly without compromising their quality or integrity. Consequently, when a structure reaches the end of its lifespan, the steel components can be effortlessly dismantled, and the steel billets can be melted down to produce new steel products. This ability to recycle steel billets reduces the necessity for extracting and refining new iron ore, thereby conserving natural resources and minimizing the environmental impact associated with mining activities. Moreover, the recycling process of steel billets requires significantly less energy compared to producing steel from raw materials. Recycling steel billets consumes around 75% less energy than manufacturing steel from scratch. This energy efficiency not only reduces greenhouse gas emissions but also contributes to cost savings during the manufacturing process. By utilizing recycled steel billets in structure construction, we can mitigate the carbon footprint and promote sustainable practices within the construction industry. Additionally, the utilization of steel billets in structures provides practical advantages. Steel is renowned for its strength, durability, and resilience, making it an ideal material for constructing robust and long-lasting structures. By incorporating steel billets, structures can be designed to withstand various environmental conditions, such as earthquakes and hurricanes, guaranteeing the safety and longevity of the building. This aspect of longevity is crucial in terms of recyclability since it allows the structure to fulfill its purpose for an extended period before being recycled. In conclusion, steel billets significantly contribute to a structure's overall recyclability. Their ability to be recycled endlessly, reduced energy consumption during the recycling process, and practical advantages like strength and durability make steel billets an exceptional choice for constructing sustainable and recyclable structures. By incorporating steel billets, we can foster a circular economy, conserve natural resources, reduce emissions, and create a more sustainable future for the construction industry.

- Q: What are the main factors affecting the ductility of steel billets?

- The main factors affecting the ductility of steel billets are the composition of the steel, the temperature at which it is processed, and the amount of strain applied during shaping.

- Q: What are the common grades of steel used for billets?

- The grades of steel commonly used for billets can vary depending on the intended application and specific requirements. However, there are several widely used grades: 1. Carbon Steel: Carbon steel billets are popular due to their affordability, high strength, and durability. Grades like AISI 1018, 1020, 1045, and 1060 are commonly chosen for general-purpose uses. 2. Alloy Steel: Alloy steel billets are blended with specific alloying elements to enhance their mechanical properties, such as strength, toughness, and corrosion resistance. AISI 4140, 4340, and 8620 are frequently utilized for applications that require increased strength, heat resistance, or wear resistance. 3. Stainless Steel: Stainless steel billets are selected for their excellent corrosion resistance and attractive appearance. Grades such as 304, 316, and 420 are commonly employed in various industries, including construction, automotive, and food processing. 4. Tool Steel: Tool steel billets are specially designed to possess high hardness, wear resistance, and toughness. Grades like AISI O1, D2, and A2 are commonly used in the production of cutting tools, dies, and molds. It is important to note that choosing the appropriate grade of steel depends on specific application requirements, such as mechanical properties, corrosion resistance, and temperature resistance. Seeking advice from a metallurgist or an industry expert can assist in determining the most suitable grade of steel for billet production.

- Q: What are the challenges faced by the steel billet industry?

- The steel billet industry encounters numerous obstacles that affect its operations and profitability. One notable challenge is the ever-changing global demand for steel products. Economic cycles exert a significant influence on the industry, directly impacting the demand for steel billets. When the economy experiences a downturn or slower growth, the demand for steel products decreases, resulting in excess inventory and reduced prices. Consequently, steel billet manufacturers face lower profit margins and struggle to sustain their operations. Additionally, the industry confronts fierce competition from other steel producers, particularly those in emerging markets. Countries like China and India have considerably expanded their steel production capacities in recent years, leading to a surplus in the global market. This oversupply drives down prices, making it arduous for steel billet manufacturers to compete on cost and maintain profitability. Moreover, the availability and pricing of raw materials pose another significant challenge for the industry. The production of steel billets necessitates a consistent supply of iron ore and other raw materials, which are susceptible to price fluctuations and disruptions in the supply chain. Any interruptions or fluctuations in the availability or cost of these raw materials can adversely affect the overall cost structure and profitability of the steel billet industry. Furthermore, environmental regulations and concerns about sustainability present an additional hurdle for the steel billet industry. Steel manufacturing is a resource-intensive process that generates substantial emissions and waste. As governments and consumers become more conscientious about environmental issues, steel billet manufacturers must invest in cleaner technologies and comply with stricter regulations. These investments can be costly and impact the industry's profitability and competitiveness. Lastly, the industry grapples with the challenge of technological advancements and innovation. To enhance production processes, improve product quality, and meet evolving customer demands, steel billet manufacturers must consistently invest in research and development. Staying abreast of the latest technological advancements necessitates significant investment, which can be particularly challenging for smaller players in the industry. In conclusion, the steel billet industry confronts various challenges, including fluctuating global demand, intense competition, raw material availability and pricing, environmental regulations, and technological advancements. Adapting to these challenges requires strategic planning, continuous improvement, and investment in innovation to remain competitive and sustainable in the market.

Send your message to us

Q235/3SP 110MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords