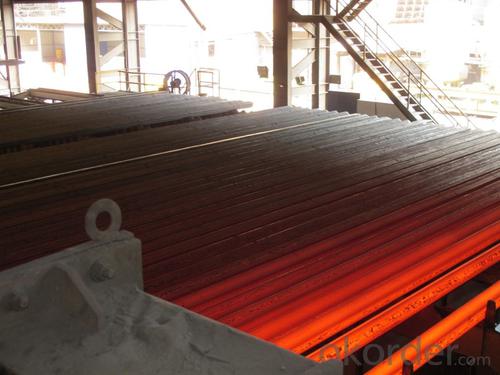

Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Difference between medium frequency continuous casting billet and electric furnace continuous casting billet

- 3, intermediate frequency furnace can not decarburization, gas and inclusion content in steel such as H element content is high, the steel has high strength, hydrogen embrittlement characteristics, lower elongation, plastic failure, and electric arc furnace on the contrary.4, even smelting high carbon steel, alloy tool steel or casting, because of the above process defects, the quality of steel is still better than the electric steel, but sometimes the demand is not high, you can use

- Q: How are steel billets shaped into other forms?

- Steel billets are shaped into other forms through a process called hot or cold working. In hot working, the billets are heated to high temperatures and then shaped using various methods like rolling, forging, or extrusion. Cold working involves shaping the billets at room temperature through processes such as drawing, bending, or pressing. These techniques allow the steel billets to be transformed into different shapes and sizes according to the desired end product.

- Q: What are the different types of surface finishes available for steel billets?

- The different types of surface finishes available for steel billets include hot rolled, cold rolled, pickled and oiled, and galvanized finishes.

- Q: What are the common sizes and dimensions of steel billets?

- Steel billets are produced through continuous casting or hot rolling methods and are semi-finished products. The industry and intended use of the billets determine their sizes and dimensions. While there are common sizes and dimensions used in various applications, they can vary. The size range for steel billets is typically between 100mm and 150mm square. These billets are usually around 6 meters long, but this may differ based on customer needs or the manufacturing process. Round steel billets with diameters ranging from 100mm to 200mm are also commonly produced. The weight of steel billets can range from a few hundred kilograms to several metric tons. The length, cross-sectional area, and density of the steel used determine the weight. Most steel billets fall within the 1 to 5 metric tons range. It is important to understand that these sizes and dimensions can differ among manufacturers, and different industries may have specific requirements. For instance, the automotive industry may require larger or smaller billets based on the parts they produce. In conclusion, steel billets typically have sizes and dimensions between 100mm and 150mm square, with lengths of around 6 meters. Round billets can have diameters ranging from 100mm to 200mm. The weight of a steel billet can vary from a few hundred kilograms to several metric tons. However, it is crucial to consider that these measurements can vary depending on the industry and customer requirements.

- Q: What is the difference between carbon three plants and carbon four plants?

- The mesophyll cells of carbon three plants are more dispersed, and there are no chloroplasts in bundle sheath cells. Photosynthesis is only carbon three cycle, and the utilization rate of carbon dioxide is low. It usually lives in temperate zone.Four carbon plant mesophyll cells arranged regularly, the formation of two circles of the "ring" and bundle sheath cells, bundle sheath cells have no chloroplast grana, photosynthesis has three carbon cycle and carbon cycle four, higher utilization rate of carbon dioxide, the general life in tropical and subtropical regions.The initial product of CO2 assimilation is not photosynthetic carbon cycle in three carbon compounds 3- phosphoglycerate, but four carbon compounds malic acid or aspartic acid plant.

- Q: What is the typical weight of a steel billet?

- The typical weight of a steel billet can vary depending on the specific dimensions and requirements, but it is commonly found to range between 1,000 to 5,000 kilograms or 2,205 to 11,023 pounds.

- Q: What is the chemical composition of a typical steel billet?

- The composition of a typical steel billet, which serves as a semi-finished material for various steel products, primarily consists of iron and carbon. However, the specific chemical composition can differ based on the grade and intended application of the steel billet. Alongside iron and carbon, different elements like manganese, silicon, sulfur, and phosphorus may also be present in varying quantities. These elements are incorporated to confer specific properties to the steel, such as increased strength, improved machinability, or enhanced corrosion resistance. To ensure the desired mechanical and chemical properties are attained, the exact composition of a steel billet is meticulously regulated during the manufacturing process.

- Q: What are the main factors affecting the formability of stainless steel billets?

- The formability of stainless steel billets is influenced by several key factors. These factors include the steel's composition, the forming temperature, the grain size and structure of the material, and the level of deformation applied during the forming process. To begin with, the composition of the stainless steel billet is a critical factor in determining its formability. The steel's composition, including the presence of alloying elements like chromium, nickel, and molybdenum, impacts its mechanical properties. For instance, higher levels of chromium can enhance corrosion resistance but may reduce formability. Therefore, selecting the appropriate stainless steel grade is essential to ensure optimal formability for a specific application. Furthermore, the temperature at which the stainless steel billet is formed is influential. Elevated temperatures increase the steel's ductility and, consequently, its formability. Heating the billet lowers its yield strength and facilitates easier deformation. However, excessive heating can result in grain growth and diminished mechanical properties. Thus, finding the right balance between temperature and formability is crucial. The grain size and structure of the stainless steel billet also affect its formability. In general, materials with finer grains exhibit better formability compared to those with coarser grains. Finer grains allow for more uniform deformation and reduce the likelihood of cracking or tearing during forming processes. Additionally, the presence of microstructural features like precipitates or twins can also impact the formability of stainless steel billets. Lastly, the amount of deformation applied during the forming process has a significant effect on the formability of the stainless steel billet. Excessive deformation can lead to strain hardening, making the material less ductile and more prone to cracking. Thus, careful control of the amount and distribution of deformation is necessary to achieve optimal formability. In summary, the formability of stainless steel billets is influenced by the composition of the steel, the forming temperature, the grain size and structure of the material, and the level of deformation applied during the forming process. Understanding and managing these factors are essential for achieving the desired formability and ensuring successful manufacturing of stainless steel components.

- Q: How are steel billets shaped into rods or wires?

- Steel billets are shaped into rods or wires through a process known as hot rolling. The billets are heated to high temperatures and then passed through a series of rollers, which gradually reduce their size and shape them into the desired rod or wire form. This process allows for precise control over the dimensions and properties of the final product.

- Q: What are the different surface treatments available for steel billets?

- There are several surface treatments available for steel billets, including shot blasting, pickling, phosphating, and galvanizing. Shot blasting involves propelling abrasive materials at high speeds to remove rust and scale from the surface. Pickling involves immersing the billets in an acid solution to remove oxide layers and impurities. Phosphating applies a layer of phosphate coating to enhance corrosion resistance and improve paint adhesion. Galvanizing involves applying a zinc coating to protect the surface from corrosion.

Send your message to us

Q235/3SP 80MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords