PVDF PE Coated Color Aluminum Coil for Gutter Machine ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Specifications

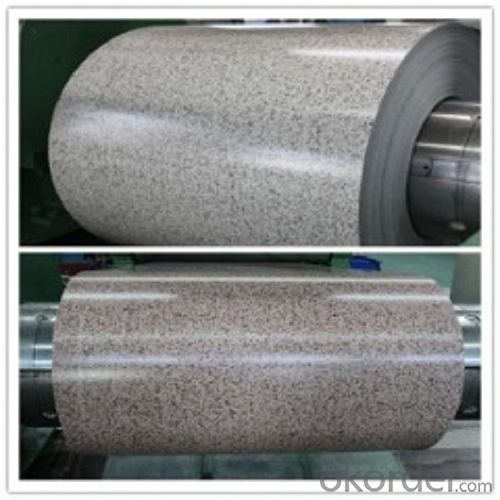

Painted Aluminium Coil

1) Temper: H14, H18, H24 mainly.

2) Alloy 1100, 1050, 3003,3004, 5052, 8011 etc

3) Origin: China

Painted Aluminium Coil:

1) The type of paint: PE, PVDF, PA, PU

2) Thickness coating: PVDF: More then 25 micron; PE, more then 18 micron.

3) Paint supplier: PPG (PVDF)

4) Interior diameter: Mainly in 405mm, 505, mm

5) Width: Less then 1600mm, sheets are also available

6) Color: Panton, RAL or refer to customers' counter sample.

7) Coating hardness: (pencil hardness) more than 2H

8) Impact resistance: No cracking and peeling (50kg/cm, ASTMD-2794: 1993)

9) Flexibility (T-bend): No more than 2T

10) MEK resistance: More than 100

The base of Painted Aluminium Coil details:

1) Temper: H14, H18, H24 mainly.

2) Alloy 1100, 1050, 3003, 3004, 3005, 5052, 8011 etc

3) Origin: China

4) MOQ: 5 tons each size

5) Lead Time: Within 20 days

6) The term of payment: T/T, irrevocable L/C at sight

7) Application: Curtain wall, roof, internal and external wall, ACP, Door

l Packaging & Delivery:

Packaging Details: 1.with wooden pallet packing.

2.standard fumigated wooden package.

3.other packing methods by customer's requirement.

Delivery Details: 30-40days

l Company Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 10 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils are used in the production of sporting goods primarily for their lightweight and durable properties. They are commonly used in the manufacturing of sports equipment such as baseball bats, tennis rackets, and bicycles. The coils are shaped, formed, and molded into the desired product, providing strength and flexibility while reducing overall weight. This allows athletes to have better control, enhanced performance, and reduced fatigue during sports activities.

- Q: I recently had to have a course of B-12 injections (my digestive system was not properly absorbing other forms). While I felt a significant improvement in mood, energy and memory, I was very concerned to discover that the B-12 shot came with a little something extra: aluminum! I'm wondering if the benefits outweigh the potential risks - why is aluminum placed in the injection? (Are there metal free versions out there?)

- Aluminum salts have been used in vaccines for over 80 years now. They are thought to increase the body's immune response to the vaccines although it is not clear to researchers how this works. However, there is no evidence that it is harmful and the only side effect seems to be increased reddness. The odd thing is that there is usually some sort of metal in any vaccine/shot. If not aluminum salts, there's thimerosal (a mercury-based preservative). The CDC says, btw, that there is no proof that thimerosal causes any harm. However, some studies show a link between thimerosal, aluminum, and a host of other preservatives added to vaccines to autism in children. No news on how it affects adults, but research is being done with respect to Alzheimer's disease. Speak to your doctor to find out he/she has 'metal free' versions of vaccines and about your concerns. Such vaccines are available but are usually very costly to obtain manufacture so doctors usually don't order them as a result.

- Q: What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils possess a multitude of possible uses across various industries. The construction industry heavily relies on anodized aluminum coils, utilizing them for cladding and façade systems. The anodized coating enhances the aluminum's durability, weather resistance, and aesthetic appeal. Its ability to withstand harsh environmental conditions, such as UV radiation, saltwater exposure, and extreme temperatures, makes it an optimal choice for building exteriors. The automotive industry also benefits significantly from anodized aluminum coils. The anodized coating adds a protective layer that enhances the aluminum's corrosion resistance, making it suitable for a wide range of automotive components. These coils can be used for trim, body panels, window frames, and other parts that require both durability and an attractive appearance. Consumer electronics manufacturing also utilizes anodized aluminum coils due to their scratch resistance, electrical insulation, and heat dissipation properties. The anodized coating makes it suitable for electronic enclosures, heat sinks, and connectors. Moreover, the ability to achieve vibrant colors through anodization allows for customizable designs that appeal to consumers. The heating, ventilation, and air conditioning (HVAC) industry extensively uses anodized aluminum coils due to their lightweight nature and excellent heat conductivity. Heat exchangers, air conditioning coils, and evaporator coils commonly utilize these coils. The anodized coating provides protection against corrosion caused by moisture and other environmental factors, ensuring the longevity and efficiency of these HVAC components. Furthermore, the food and beverage industry finds applications for anodized aluminum coils due to the hygienic surface provided by the anodized coating. It is easy to clean and resistant to bacterial growth, making it suitable for food processing equipment, storage tanks, and packaging materials. This ensures the safety and quality of the products. In conclusion, anodized aluminum coils possess vast and diverse potential applications, ranging from construction and automotive to electronics and food processing. The unique combination of durability, corrosion resistance, heat dissipation, and aesthetic appeal makes anodized aluminum coils a versatile material that finds use in numerous industries.

- Q: My front door is scraping the aluminum frame door jam thing on the bottom. Also underneith the door itself it seems like there is a huge aluminum device covering the whole bottom of it and an aluminum weather stipper built into that. Is my only option to have the door pulled off. Or could I maybe grind of file down the aluminum on the bottom?

- Check your hinges first. typically your upper hinge has become loose or bent. If it is bent you could use wood 2X4 as lever under bottom corner and pry it back into position.

- Q: What are the different types of end conditions for aluminum coils?

- The different types of end conditions for aluminum coils include plain end, slit end, trimmed end, and sheared end.

- Q: at what state is aluminum at room temperature?what are aluminums physical properties?what is aluminum obtained from?

- 1. Solid, liquid, or gas... I bet you can guess. 2. There's a mess of them in the right side info box of the wikipedia article:

- Q: Are aluminum coils suitable for heat exchangers?

- Aluminum coils are indeed a fitting choice for heat exchangers. This is because aluminum possesses exceptional thermal conductivity, making it highly efficient and effective in transferring heat between mediums. Its ability to swiftly transfer heat from one medium to another is particularly advantageous for heat exchangers that require efficient heat transfer. Furthermore, aluminum coils are lightweight, resistant to corrosion, and boast excellent durability. These qualities contribute to their popularity in a wide range of applications, including heat exchangers. The corrosion resistance of aluminum ensures that the coils can endure harsh environments and prevent the occurrence of rust or corrosion, thereby prolonging the heat exchanger's lifespan. Moreover, aluminum coils are easily moldable and can be shaped into various forms, allowing for flexibility in designing and constructing heat exchangers. This adaptability makes them suitable for a diverse array of applications, such as HVAC systems, refrigeration units, and automotive cooling systems. In conclusion, the high thermal conductivity, lightweight nature, corrosion resistance, durability, and versatility of aluminum coils make them well-suited for heat exchangers. These properties establish aluminum coils as an excellent choice for achieving efficient heat transfer in numerous industries.

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Both my Speed Stick Original Scent and Old Spice High Endurance Original contain no Aluminum. They are both deodorants, NOT antiperspirants, which work differently. Deodorants do not inhibit sweating, they just keep you from smelling funky from it. Hence the name DEodorant. Antiperspirants on the other hand DO inhibit sweating as well as keep you smelling fresh. They do so by clogging your pores! And if there is aluminum in it, it can cause irritation on some people. Most antiperspirants contain aluminum, most deodorants do not. Whichever you end up going with just read the back label.

- Q: What is the typical conductivity of aluminum coils?

- The typical conductivity of aluminum coils is relatively high, with values ranging from 34 to 38 million Siemens per meter (MS/m) at room temperature. Aluminum is known for its excellent electrical conductivity, which is why it is widely used in various electrical applications, including power transmission lines, electrical conductors, and coils. This high conductivity allows for efficient and effective flow of electric current through aluminum coils, making them suitable for conducting electricity in a reliable and efficient manner.

- Q: * How is hitting with a aluminum Wiffle Ball feel and work out?* Did you like the results you had hitting with a aluminum Wiffle Ball bat?

- I did her like this I did her like that I did it with a wiffle ball bat

Send your message to us

PVDF PE Coated Color Aluminum Coil for Gutter Machine ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords