1060 Aluminum Coil Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

| Aluminum Alloy: | AA1100, 1050, 1060, 3003, 3004, 3005, 3103, 3105, 5005, 5052, 5083, 5754, 6061, 8011 |

| Temper: | O, H16, H18, H22, H24, H26, H28 |

| Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08, 0.18, 0.28, 0.38, 0.48, 0.6, 0.8, 1 mm) |

| (0.1, 0.15, 0.25, 0.35, 0.45 mm) | |

| Coil Width: | 30~1520mm china price color coated aluminium coil |

| Core Diameter: | 150/ 405/ 505mm |

| Coil Weight: | 1~2.5 tons each coil for 3003 colorful aluminium coil for acp |

| Coating Type: | PE, PVDF, back coatting, ACRYLIC, feve |

| Surface Type: | Smooth, Embossed, Mill finish, Coated, Brushed, etc. |

| Glossness: | 10-90%(EN ISO-2813:1994) |

| Coating Thickness: | PE: more than 18 +-1micron |

| PVDF: more than 25+-1micron | |

| Back Coating: 8~10+-1micron | |

| Coating Color: | Color A: pure white, ivory, white matte, yellow white, opal, light gray, aluminum natural color etc. |

| Color B: blue, yellow, gray, black, dark gray etc. | |

| Color C: white silver gray, flash silver, champagne etc. | |

| Color D: violet, pure orange, orange, bright red, china red, dark blue, brown, green, laker blue, flash gold yellow etc. | |

| Paint Hardness: | More than 2H |

| Coating Adhesion: | 5J(EN ISO-2409:1994) |

| Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Advantage: | 1.High temperature resistant 3003 colorful aluminium coil for acp |

| 2.Weathering resistant | |

| 3.Scrubbing resistant | |

| 4.Sound insulation | |

| 5.Acid or alkali proof,Fireproof | |

| 6.Light weight material is easy to construct and install | |

| Packing Details: | Five-layer carton, strong polar fumigation wooden pallet, steel belt fastened outside,worthy shipping by sea. |

| Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM,Mechanical Property: GB/T 3880-2006, ASTM |

| Application: | acp, aluminum composite panel, roof, gutter, ceiling, facade, wall cladding, gutter,aluminum honeycomb panel,roller shutter, rolling shutter, truck body, rolling shutter door, etc. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

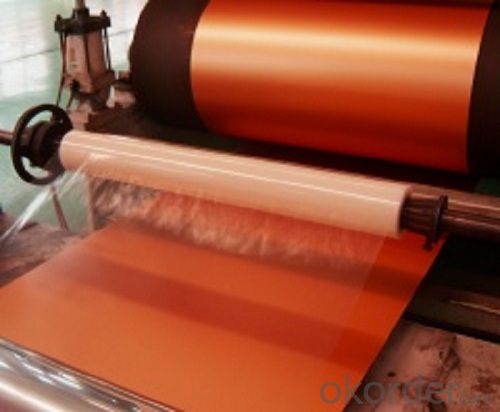

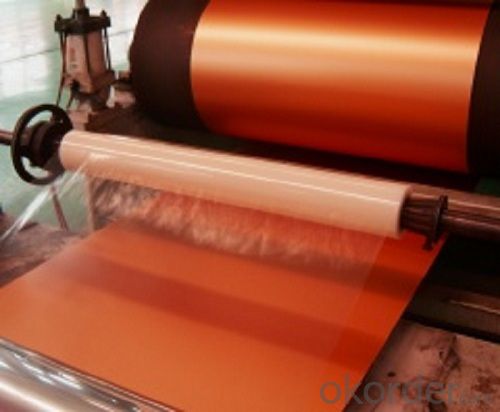

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Related technical standards of aluminium coil

- GB/T 10456-1989 anodized aluminium foilGB/T 9734-1988 chemical reagent -- General method for the determination of aluminiumGeneral specification for GB/T 9538-1988 strip cable connectorsComplexometric titration fluoride release method for the determination of three aluminium oxide content in GB/T 9489.4-1988 corundum powder twoGB/T 9438-1999 aluminium alloy castingsGB/T 8733-2000 cast aluminium alloy ingotsGB/T 6454-1986 getter aluminium zirconium alloy rings and sheets

- Q: How to use aluminum sheet to roll a 12m-long aluminum coil with a diameter of 184cm?

- According to project experience, first you should check the specification of the aluminum sheet and then design crafts such as connection method, installation and transportation according to equipment.

- Q: Can aluminum coils be used for HVAC systems?

- Yes, aluminum coils can be used for HVAC systems. They are commonly used due to their durability, resistance to corrosion, and efficiency in transferring heat.

- Q: Is it safe or advisable to use aluminum coil for wrapping food?

- <p>Using aluminum coil to wrap food is not recommended. Aluminum can react with acidic or alkaline foods, potentially leaching harmful aluminum particles into the food. It's also not designed for food contact and may not be safe at high temperatures. Instead, use food-grade aluminum foil, which is specifically designed for cooking and wrapping food, ensuring it doesn't come into contact with non-food surfaces that could contaminate it.</p>

- Q: How do aluminum coils compare to other metal coils like steel or copper?

- Aluminum coils have several distinct advantages compared to other metal coils like steel or copper. Firstly, aluminum is much lighter in weight, making it easier to handle and transport. Additionally, aluminum has excellent corrosion resistance, ensuring durability and longevity in various environments. Furthermore, aluminum coils have superior thermal conductivity, allowing for efficient heat transfer. Lastly, aluminum is more cost-effective compared to copper, while still providing reliable performance. Overall, aluminum coils offer a compelling combination of lightweight design, corrosion resistance, thermal conductivity, and cost-effectiveness when compared to steel or copper coils.

- Q: I wrap everything with aluminum foil and bake it in the oven -- fish, meat, vegetables. Is this really safe? Or safe when done occasionally? Or should I find a new way?

- I use aluminium foil often for baking however I use baking paper between the food and the foil. I am sure it is safe to use foil, however I find that on occasions the foil sticks to the food, so I use the non stick paper between. I hope this helps.

- Q: Im trying to make a aluminum ring. I want it to be rock hard. PLZZAnswers that work get best answer

- First off, use the right alloy. Making the right alloys yourself is a recipe for disaster so it is best to buy them. There are a number of inexpensive alloys of aluminum that can be hard enough to be used as a ring. 5000 series, 6000 series and 7000 series are all pretty hard. If the alloy has a T in front of it, that means you can temper it by heating it then cooling it at a given rate (usually fast). To make the surface just a little bit harder, you can then anodize it (check out the yahoo group anodizing 101 for details - you can get some really pretty colors this way) and seal it. You can also coat it with a thin layer of a clear acrylic. Of course, if you really want ROCK hard, you can oxidize it, combine it with oxygen to make Al2O3 which is corundum, more commonly known as ruby/sapphire - one of the hardest materials known to man. You could also look up someone on the web that makes synthetic rubies and ask them to make you a ring from the ruby itself...then maybe do some engraving and gold leaf on it so that the metal is set in the gem rather than vice versa! That would be pretty cool! Also about as hard as you can get and totally unique.

- Q: 1) Do you recycle aluminum (soda cans, etc.)?2) Why do or don't you recycle aluminum?3) Does it make a difference to the economy whether we recycle or not?4) Does it make a difference to the environment whether we recycle or not?5) What do you think would help people to recycle more? Such as a reward, information, resources, etc. Don't feel the need to limit responses. Thank you.

- 1) Do you recycle aluminum (soda cans, etc.)? Yes, as much as possible. 2) Why do or don't you recycle aluminum? I recycle cans so the material can be reused in new products and applications. 3) Does it make a difference to the economy whether we recycle or not? Yes, it provides jobs and increases the availability of green materials which have been popular for a number of years. 4) Does it make a difference to the environment whether we recycle or not? Yes, aluminum leeching into the earth via landfill or other trash is not good. 5) What do you think would help people to recycle more? Such as a reward, information, resources, etc. Make it cool and popular to recycle. Recycling is far more prevalent now than it was 20 years ago when I started doing so on a regular basis.

- Q: Can aluminum coils be used for magnetic purposes?

- No, aluminum coils cannot be used for magnetic purposes as aluminum is not a magnetic material.

- Q: Can aluminum coils be used in the manufacturing of furniture?

- Indeed, furniture manufacturing can incorporate aluminum coils, which boast attributes of being both lightweight and durable. Consequently, this material is highly suitable for furniture production. Notably, it is frequently employed in the crafting of outdoor furniture due to its exceptional resistance against rust and corrosion. The malleability of aluminum coils permits the creation of furniture pieces in a diverse range of shapes and sizes. Furthermore, aluminum can be effortlessly tailored and adorned with a variety of coatings or paint, enabling it to harmonize with any desired aesthetic. In summary, opting for aluminum coils in furniture manufacturing proves to be a versatile and pragmatic decision.

Send your message to us

1060 Aluminum Coil Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords