4x8 Sheets of Aluminum 090 Thick PVDF Color Coated Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

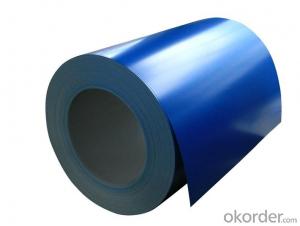

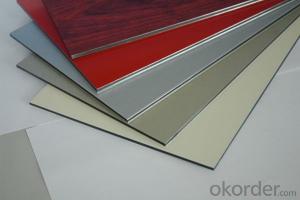

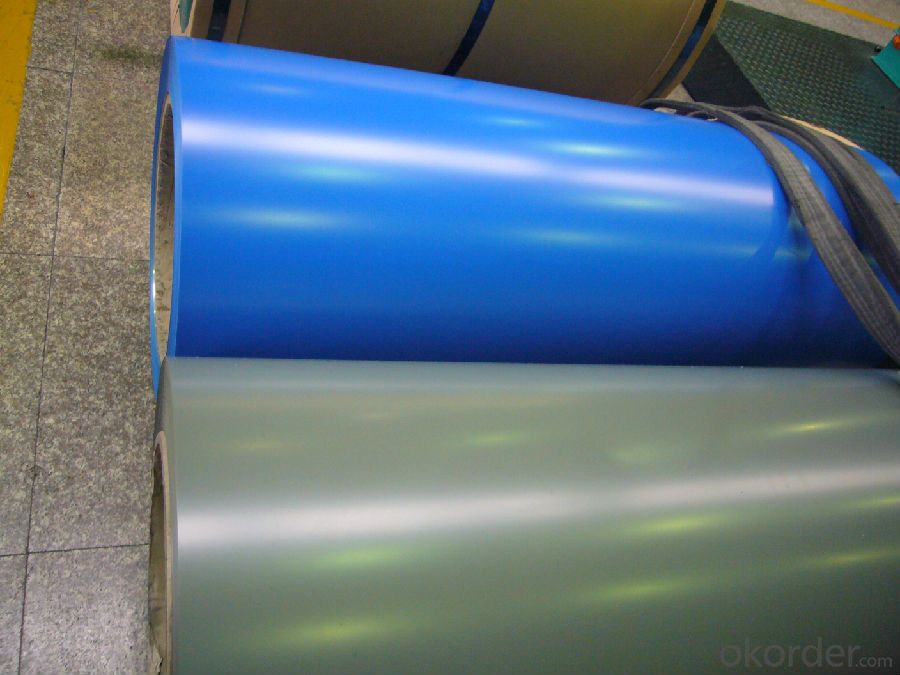

1.Structure of PVDF Color Coated Aluminium Coils for ACP

PVDF Color Coated Aluminium Coils for ACP are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of PVDF Color Coated Aluminium Coils for ACP

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- This Site Might Help You. RE: Are today's aluminum cans bad for our health? I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Q: What is the weight of a standard aluminum sheet?

- The weight of a standard aluminum sheet can vary depending on its dimensions and thickness. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter. To determine the weight of a specific aluminum sheet, you would need to know the dimensions (length, width, and thickness) and multiply them to obtain the sheet's volume. Then, you can multiply the volume by the density of aluminum (2.7 g/cm³) to calculate the weight in grams.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: Can aluminum sheets be embossed or engraved?

- Aluminum sheets have the capability to be embossed or engraved. The act of embossing entails the formation of a raised design or pattern on the aluminum sheet's surface, whereas engraving involves the cutting or etching of a design into the surface. These techniques are applicable for incorporating decorative or functional elements into aluminum sheets. In numerous industries, such as automotive, aerospace, signage, and architectural applications, embossed or engraved aluminum sheets are commonly employed. The process of embossing or engraving aluminum sheets typically necessitates the utilization of specialized machinery or tools to achieve the desired design.

- Q: Are aluminum sheets easy to work with?

- Aluminum sheets, in general, prove to be easily manageable. Being a light and flexible metal, aluminum allows for easier cutting, shaping, and manipulation compared to its counterparts. It boasts the ability to be effortlessly bent, formed, and welded, granting access to a variety of fabrication methods. Furthermore, aluminum sheets exhibit excellent resistance to corrosion, which enhances their user-friendliness. Whether the goal is constructing lightweight structures, fabricating components, or crafting intricate designs, aluminum sheets offer versatility and convenience across numerous applications.

- Q: What are the different types of patterns available for textured aluminum sheets?

- There are various types of patterns available for textured aluminum sheets, including stucco, diamond, pebble, hammered, and brick patterns. These patterns are created through embossing or rolling processes, providing different textures and visual effects for decorative or functional purposes.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- The color of aluminum sheet is single, the quality is not high; the price of stone is high; the color difference is serious; the radiation is not environmental; and the resource is limited; the supply is difficult to guarantee; the weight of the tile is light; the radiation is zero; the pollution resistance is strong. Rich in color, especially in the production process, forms of diversification, to meet high, medium and low-end customer base needs. Zhejiang ruigao company is China and Asia's first introduction of the ceramic plate production line, their R & D capability is recognized. The pursuit of perfection, the introduction of new ideas, and the concept of customization for architects to realize their dreams and fashion designs for the architecture have opened wider space for the wide application of ceramic panels and curtain walls. In fact, the application of ceramic is not limited to curtain wall, but also applied to the lighting effect display, interior decoration and so on. Hi! In short, there are any problems can be exchanged with each other.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- if a candle is 1000 degrees u can melt aluminum with it, it wont happen straight away, you have to give the metal a long time to heat up as it conducts heat it will take ages, you will prob let go or get bored before the metal has chance to heat up

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation.

Send your message to us

4x8 Sheets of Aluminum 090 Thick PVDF Color Coated Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords