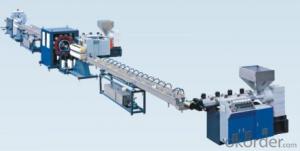

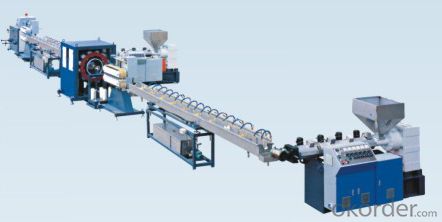

PVC Fiber Reinforced Hose Machine Extrusion Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Fiber Reinforced Hose Machine Extrusion Production Line

Production Description

PVC fiber reinforced hose also named PVC network tube, commonly known as plastic snakeskin tube, transparent, portable, with high tensile strength, and good resistance to high pressure, hardening and erosion, beautiful looks, and nontoxicin foodstuffs and sanitation lines

main uses

It is really the best choice for conveying air ,water, gas, oil and some other liquid and gas material with its working temperature ranges from-5 to 65.

now also widely used in pouring the garden ,lawn.Suitable for conveying the pressure or corrosive gas, liquid .widely used in the machinery , coal mineral , petroleum .chemical industry ,agriculture irrigation ,construction, civil (solar water heater ,gas cylinder)etc.

Machine configuration

exturder | 2sets |

Cooling tank | 2sets |

Hauling machine | 2sets |

Winding machine | 1set |

mould | 1set |

Coiling pipe bender | 1set |

drier | 1set |

High speed kneading machine | 1set |

Technical parameters

Model | YG-XW65 | YG-XW45 |

Extruder | XW65/28 | XW45/28 |

Screw material | 38CrMoALA | |

Screw rotate speed(r/min) | 0-70 | |

Diameter Range(mm) | Φ12-Φ50 | Φ6-Φ14 |

Output (kg/h) | 40-75 | 40-90 |

Installed Power(KW) | 50 | 35 |

Hauling speed(m/min) | 0-18 | |

Weight(kg) | 6000 | |

Process flow:

High speed kneading machine (mixing materials)---mould---extruder 1(innermost layer PVC pipe)------cooling tank 1---hauling machine 1 ---winding machine (fiber line that is the second)---dryer---extruder 2(the most outer PVC pipe )----cooling tank 2---hauling machine 2---coiling pipe bender ----package.

promise:

Our Company has more than 10 years in the field of PVC machine .NO.1 machine quality ,

competitive price ,and excellent after sales service ,will make you covince

If you have any question .feel free to contact me

looking forward to cooperate with you in near future.

- Q: What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q: I want to use POM plastic to do mechanical disc cam, processed with sheet metal. (small dosage)Do other plastics have mechanical strength?

- Can be processed, but pay attention to cutting tools to be sharp, cutting force should be small, and fully cooled.The material is of good mechanical strength, and I know nothing in the plastic can match it.

- Q: What kind of equipment do household workshops need to process plastic products? Can you make money? What are the sales channels?

- The biggest investment is the injection molding machine, as well as three-phase power, it is best to understand the machinery will repair the mold, there is a stable processing order, you do not need to sell it!

- Q: Plastic POM POM generally used for the production of what plastic products?

- Because of its good wear resistance, POM can be used to make plastic parts, such as gears.

- Q: The processing of plastic bottles

- The production process of plastic bottle has two kinds: the first kind is extrusion blowing process, the plastic raw materials into the extruder, the melting extruding molten parison, then put the bottle mold blow molding, cooling after removed from the mold, eliminating waste edge to be finished after. This process is mainly used to produce polyethylene, PVC plastic bottles, such as milk bottles, soy sauce bottles and so on. The second is the plastic material injection stretch blow molding process, the injection molding machine injection molding tubular billet, then put the bottle mould through stretch blow molding, cooling after the finished product is obtained. This process is mainly used to produce PET plastic bottles, such as mineral water bottles and so on.

- Q: What are the processes and machines used in the manufacture of plastic products?,

- In recent years, the proportion of plastic products is increasing rapidly in many fields, such as household appliances, instruments and meters, building materials, automobile industry, daily hardware and so on. The requirement of high precision and high performance of plastic products increases with each passing day, which makes the precision forming technology progress constantly. Injection molding is one of the most important plastic forming methods, and many factors affect the precision injection molding. 1. in the early stage of the design of plastic products, injection molding materials should be selected according to their application environment. 2. precision molds, rational design of precision injection mold is the basis and necessary prerequisite for precision products. Precision molds are indispensable to produce precision products. The precision of the die is usually affected by the temperature control of the die, the precise manufacture of the die and the choice of the plastic shrinkage when the die is designed. 2.1 control of the mold temperature due to the effect of mold temperature on shrinkage molding, but also directly affects the mechanical properties of plastic products, can also cause various defects of product surface flooding, so must keep mold in the specified temperature range, but also to make the mold temperature changes over time. In the injection molding of general precision parts, the temperature of the die is controlled mainly to increase productivity. But the impact of temperature control of mold for injection molding is great, it affects parts of the shrinkage, shape, crystallization, internal stress, so the design of mold hot loop temperature distribution at the request reasonable precise control accuracy, the best use of mold temperature machine and cold water machine control.

- Q: Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q: Would like to ask a few questions?1, waste plastics need to go through a few devices or steps to become plastic particles2, how much would it cost for the whole set of plastic particles? (I want to get a small wire first)3, if the equipment, plastic material can be any processing?4, is there any pollution in the whole process?.5, how about this prospect this year?Please have experienced predecessors to give some experience

- The question you ask is too wide. There are too many plastic parts. First of all, you have to decide what kind of plastic you want to make. We usually have PET PP, PVC, PMMA, ABS, PEAnswer the questions you ask first: 1, the most basic, you should have a crusher, washing machine, particle machine2: I'm looking for in our local welders do, that not what technical content, you will not give them to talk about the price, almost tens of thousands of dollars.

- Q: What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- has a great competitive advantage in the city of Ji'nan, 5 sets of CNC machining center, CNC lathe 2 units, the company is Chinese FAW heavy truck, China, supporting services Joyoung electric lights, Lent, Qingdao's foreign trade and other well-known enterprises, and repeatedly won the title of excellent supplier,

- Q: Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

Send your message to us

PVC Fiber Reinforced Hose Machine Extrusion Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches