Steel Reinforced Spiral Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Water Suppply Pipe, Gas Pipe Energy-saving and High Speed Extrusion Line

Product Description

HDPE Water Suppply Pipe, Gas Pipe Energy-saving and High Speed Extrusion Line Made In China absorbed and digested the advanced production technology home and abroad based on our former round dripper irrigation pipe production line, developed the third generation for this extrusion line. This line has the advantages of high extruding speed, precious punching, better cost-saving and so on.

Packaging & Delivery:

| Packaging Detail: | Best Sea transportion package to avoid damagement |

| Delivery Detail: | 100days |

Advantage:

Our company using the development HDPE,PP pipes extrusion technology

develops this kind of extrusion line.

This line features compact structure, highly automation and stable performance.

This line is widely used in producing HDPE water, gas supply pipe, double-anti pipe for mine industries.

Application:

This production line adopts the most advanced technology of Europe,it is a new research achievement of energy-saving production line,which is suitable for high speed extrusion of HDPE,PP and other polyolefin pipe.compared with common production line,the energy-saving effect reach on 35%, and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower,but also improving efficiency. This production line has nice appearance,higher automatical degree ,production reliable and stable .

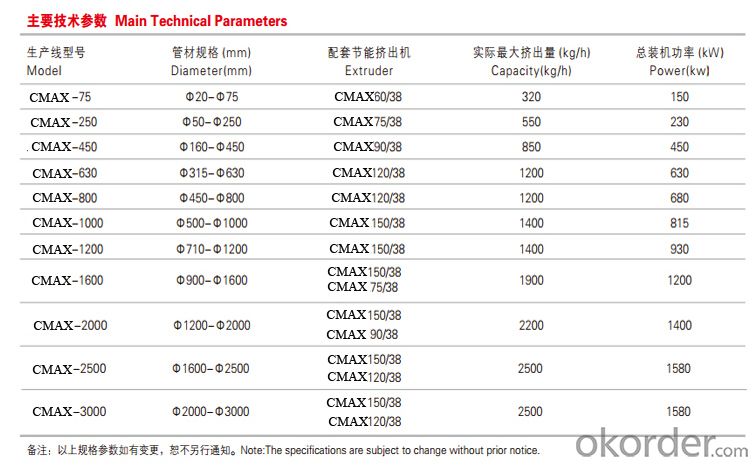

Technical parameters:

FAQ

1., How about the after service?

We have a strong team, special for after service. We can arrange engineers to do service for you.

2. How does your company do regarding quality control?

Quality is priority. We always attach great importance to quality controlling from the beginning.

3. why choose CNBM Group

We are a state-owned company which is a leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

4.Q:An extrusion machine how long ?

A single extruder could probably use a long long , It can change a screw when it hurts

5.Q: What's the price of this machine please?

A: Dear customer, for each kind of our machines, we have lots of models. Generally speaking, we design the production lines according to different requirements of different machines from different customers. Therefore, the prices are different. So please kindly inform us your requirements. For example, the raw material, the output product size, capacity and etc. The more detailed, the better. Our Engineers will design a suitable production line for you.

6.What's your company's advantages comparing with other manufacturers?

1) over 20 years experience to provide product with high quality and reasonable price.

2) High output capacity .

3) We can support engineer with overseas training.

4) Professional design team can support with the customized design.

5) Most of electric parts are use the famous/qualified brand, such as Siemens, NSK, etc.

6) Have a team of full experienced technical workers and engineers.

7) Our product passed CE,UV,SGS,etc.certification.

7. Do I have to go to China to check the machine/equipment ?

you can come to China to check the machine and the equipment. .

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- Depending on your specific specifications, if XLPE is insulated, extrusion die with small touch line, set on the use of cable diameter, large core conductor than a few tenths of good, if you like to use 70 square tube extruding mold insulation of the conductor element some is big 1 can be set according to the touch, the tensile ratio calculation, PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: What are the common extrusion molding products?

- Extrusion molding products are as follows:1 、 plastic pipe, for example: water pipe up and down;2, plastic profiles, such as: doors and windows, plastic steel profiles.3, plastic plates, such as: wood plastic doors, plastic doors,4, plastic sheet (sheet and board is the difference between the thickness, thin, thick plate), such as: mobile phone membrane.

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: What is the adjustment method of China's extrusion machine die?

- (3) line to die: suitable for small section of wire and cable adjustment. Pass the wire through the mold core, connect to the traction line, then run the glue and fine tune it. When the glue is running, adjust the screw and the traction speed, start the car, take the line sampling, and then stop to observe the thickness of the plastic layer of the sample is even, repeated several times until the tune until so, and then tighten the screws

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: Extrusion blow molding machine, storage or continuous type good?

- This is not good or bad, depends on what your product is If the product cycle large volume high capacity is bound to produce a product with storage because of your long,

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- They can see it moving.God doesn't need itSometimes you hear, fifth hand material,Cool sounds in the swirling smokeCoagulation together, I have left their land,Yesterday was a similar experience, ha ha

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

Send your message to us

Steel Reinforced Spiral Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords