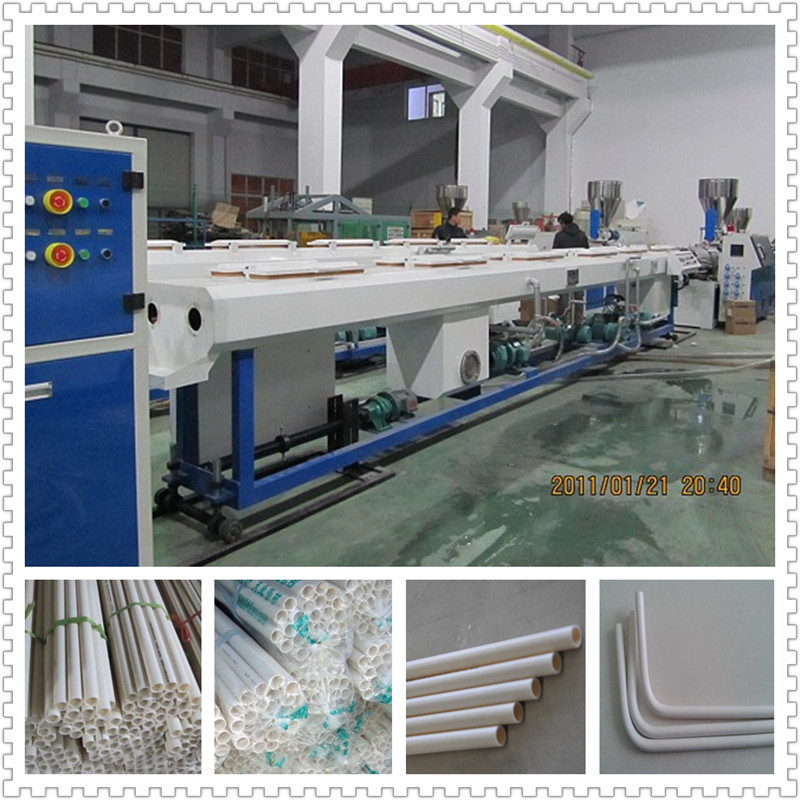

PVC electrical threading pipe production line / thread pipe / tube machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC electric threading pipe machine

This series of extrusion lines are mainly used to produce PVC drainage pipes and U-PVC,C-PVC water supply pipes.

Advanced design for screws supplies powerful safeguard for the PVC plasticization.

Unique inside oil controlling temperature system adapts different technology formulas.

Beautiful and practical stainless steel body for the vacuum calibration and spray cooling system, unique multi-section vacuum system ensures the stable sizing and cooling for pipes; special spray cooling system improves the cooling efficiency ; special water position, water temperature system make the machine more intelligent.

Hauling-off unit adopts particular pedrail structure, which is easy and convenient for operation; pedrail clamping uses mechanical and pneumatic combining system, which is more reliable.

Cutting system adopts saw blades and planetary cutting means; sumping uses hydraulic system , which ensures the smooth cross section; equipped with dust-collecting unit, which ensures the clean working environment.

Main technical data:

Extruder Model | RMSG-45/90 | RMSG-51/105 | RMSG-65/132 | RMSG-80/156 | RMSG-92/188 |

Pipe Size/mm | 20-63 | 75-160 | 110-250 | 200-400 | 315-630 |

Size Calibration Means | Vacuum | ||||

Hauling Speed(m/min) | 12 | 5 | 3.6 | 2.3 | 0.8 |

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: Why single screw extruder is controlled by high school and low?

- What is controlled by high school? I can't answer the question without saying it

- Q: What should be paid attention to in the daily maintenance of the extruder?

- Attachment(1) inspect the rolling barrel, vibrating screen, motor and so on, and leak out the sealing parts.(2) cooling equipment and piping are clean and clean, and there is no suspended impurity in industrial soft water. Water filters and water tanks should be regularly checked, cleaned, kept clean and replaced with new water.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

- Q: Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- One is the use of frequency converter connection, in accordance with the frequency converter user manual guidance method to adjust the speed, in addition to the use of electromagnetic speed control motor, through the speed box above potentiometer adjust speed.

Send your message to us

PVC electrical threading pipe production line / thread pipe / tube machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches