PTFE Coated Fiberglass Mesh Fabric Electro Galvanized Wire Mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.PTFE Coated Fiberglass Mesh Fabric Electro Galvanized Wire Mesh Description:

SpecificationsPTFE coated fiberglass mesh fabric

We manufacture different kinds with various open mesh size

PTFE coated fiberglass mesh fabric

We manufacture different kinds with various open mesh size.

Hexagonal Wire Mesh is 1 1/2" x 17 gauge, zinc coated, galvanized woven wire Paperback Stucco Netting is made for building as reinforcement wire materials for cement, gypsum plaster, masonry veneer and ceramic tile. 1 1/2" (38mm) x 17 gauge, 1/4" self-furring woven wire in rolls, hexagonal mesh is formed with a twist of 17 gauge (1.38mm) galvanized steel wire. Paperback Stucco Netting is furred at 6" (152mm) vertically.

2.Main Features of PTFE Coated Fiberglass Mesh Fabric Electro Galvanized Wire Mesh:

good corrosion resistance and oxidation resistance, serves well as strengthing, protection

1. Heat resistance property---It is able to wok stably between -60oC to 260oC.

2. Excellent non-sticky property---It easier to remove those resins, dopes, oil and other sticky things.

3. Good mechanical property with no distortion and low friction coefficient.

Applications: Being used in paper printing for protecting from the oil and other sticky things. It is widely used in PRINT INDUSTRY as conveyor belt.

Any special requirement, please contact the research department.

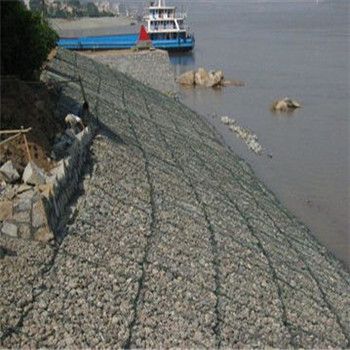

3.PTFE Coated Fiberglass Mesh Fabric Electro Galvanized Wire Mesh Images

4. PTFE Coated Fiberglass Mesh Fabric Electro Galvanized Wire Mesh Specification

Mesh | Wire Gauge(SWG) | Size(width×Length) |

1/2"

| 22,23,24,25 | 3'×100', 4'×100', 5'×100' |

3/4"

| 21,22,23,24 | 3'×100', 4'×100',5'×100'' |

5/8" | 22,23,24,25 | 3'×100',4'×100',5'×100' |

1" | 20,21,22,23 | 3'×100',4'×100',5'×100' |

(3CM) 1.09 | 19,20,21,22 | 3'×100',4'×100',5'×100'' |

(4CM) 0.847 | 18,19,20,21,22 | 3'×100',4'×100',5'×100'' |

2" (5CM) | 18,19,20,22,23 | 3'×100',4'×100',5'×100'' |

5.FAQ

①. What product specifications can be determined by customers?

A: Customers can choose the raw materials , the type of surface treatment and assembly, as well as packaing.

②.How long do orders take to produced and delivered?

Lead time varies case by case. The customers will be informed when an order is placed.

③.Do you offer samples?

Yes, we will offer samples for your reference to have a test .

- Q: On the issue of their own screen printing

- Print a colored pattern on a white shirt, I'm now nothing I wanna know what i need ...

- Q: How to get the correct fishing wire

- stroked the net, in the clean concrete on the grass and other things slowly removed, and then re-network when the network as a stroke when the knot again, and then you can then the next network.

- Q: Screen printing, how to print circular arc surface

- The cup is cylindrical, in the top of the screen will roll the cup, then the screen printing on the graphic part of the ink will be transferred to the cup.

- Q: Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

- Q: What is the commonly used mapping software for screen printing?

- screen printing is a stencil printing, it is printed with India, embossing, gravure together known as the four printing methods. The stencil printing includes transcripts, engravings, stencils and screen printing.

- Q: How to clean the screen plate

- Reset, in order to achieve the next work process to facilitate the operation of personnel cleaning wire mesh, a substantial increase in production efficiency, which due to cleaning the liquid can be used in the machine to achieve recycling,

- Q: Screen printing ink firmness problem

- If not enough, it can only change solvent-based ink, the solvent ink tension is small, ink layer spread, drying speed, adhesion will be much better, but the volatile substances on the human body and the environment is harmful, and flammable and explosive, need

- Q: Screen printing, how to choose the screen

- You have to choose according to different moments, printing different products, imports a little better

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: Screen printing and printing the difference

- Full name screen printing is a stencil printing, it is printed with flat, embossed, gravure together known as the four printing methods.

Send your message to us

PTFE Coated Fiberglass Mesh Fabric Electro Galvanized Wire Mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords