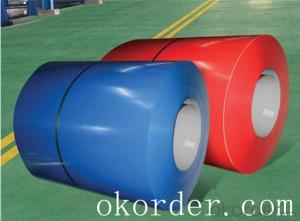

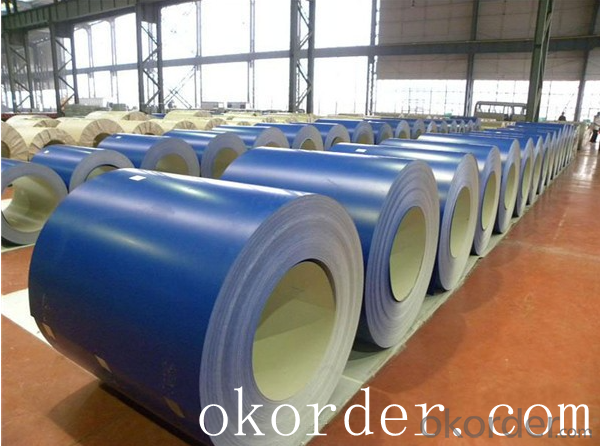

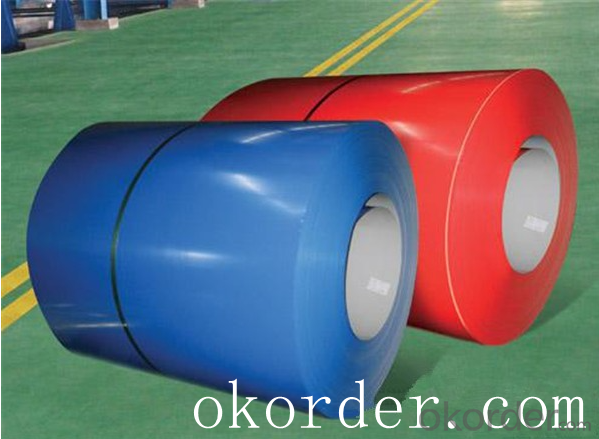

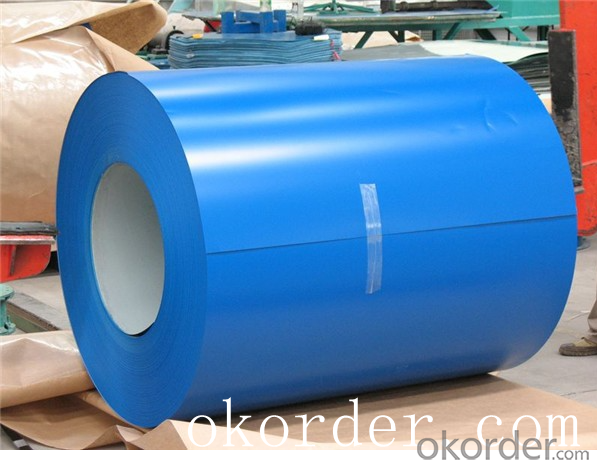

Prime quality prepainted galvanized steel 615mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

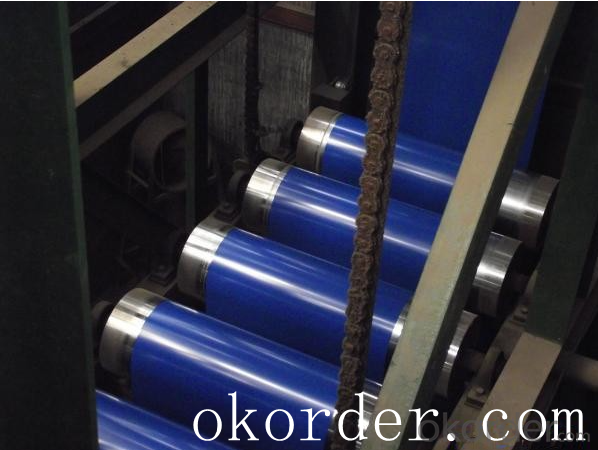

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: What are the different surface treatments for improved wear resistance in steel billets?

- There are several surface treatments that can be applied to steel billets to enhance their wear resistance. Some common methods include carburizing, nitriding, and hard chrome plating. Carburizing involves introducing carbon into the surface of the billet through a heating process, creating a hardened layer. Nitriding, on the other hand, involves introducing nitrogen into the surface to form a hard nitride layer. Hard chrome plating is another option where a layer of chromium is electroplated onto the surface, providing excellent wear resistance. These treatments can significantly improve the durability and performance of steel billets in various applications.

- Q: What is the role of steel billets in the manufacturing of construction excavators?

- Steel billets play a crucial role in the manufacturing of construction excavators. These billets, which are essentially semi-finished steel products in the form of a rectangular solid, serve as the primary raw material for constructing various components of excavators. One key aspect of steel billets is their high strength and durability. The construction industry demands materials that can withstand heavy loads, intense pressure, and harsh working conditions. Steel billets possess these characteristics, making them ideal for manufacturing excavators that are capable of withstanding the rigors of construction sites. During the manufacturing process, steel billets are heated and shaped into various components of the excavator. These components include the mainframe, booms, arms, and buckets – all of which require high-strength materials to ensure structural integrity and longevity. Additionally, steel billets allow for precise customization and fabrication. Manufacturers can mold and shape the billets into specific sizes and dimensions required for different parts of the excavator. This flexibility ensures that the components fit together seamlessly, enhancing the overall performance and functionality of the machine. Furthermore, steel billets provide excellent weldability. As excavators undergo constant stress and movements, welding is a crucial process for joining the various components. Steel billets enable strong and reliable welds, ensuring that the excavator remains structurally sound and capable of performing heavy-duty tasks. Overall, the role of steel billets in the manufacturing of construction excavators is indispensable. Their high strength, durability, customizability, and weldability make them the ideal raw material for constructing the robust and reliable machines that are required for the demanding nature of the construction industry.

- Q: Billet heating furnace billet temperature reached, steel will be adhesion

- As soon as the melting point is reached, the part melts before sticking. But heating will swell a lot, you need to leave enough space.

- Q: How do steel billets contribute to the manufacturing of marine equipment?

- Steel billets play a crucial role in the manufacturing of marine equipment. These billets are semi-finished products that are used as raw materials in the production of various marine components such as ship hulls, propellers, shafts, and other structural parts. One of the primary reasons steel billets are preferred in the marine industry is their excellent strength and durability. Ships and other marine equipment are subjected to harsh conditions including extreme temperatures, corrosive saltwater, and heavy loads. Steel billets, being made of high-quality steel, possess the necessary strength to withstand these challenging environments, ensuring the long-term reliability and safety of the equipment. Moreover, steel billets provide the flexibility to create complex shapes and designs required in marine equipment manufacturing. The billets can be easily molded and forged into desired shapes, allowing for the creation of intricate components with precise specifications. This versatility enables the production of different marine equipment parts that are essential for the efficient operation of vessels. Another advantage of using steel billets in marine equipment manufacturing is their corrosion resistance. Steel billets can be treated with various protective coatings or alloys to enhance their resistance to corrosion caused by exposure to seawater. This corrosion resistance is vital in preserving the integrity and longevity of marine equipment, ensuring they can withstand the harsh marine environment for extended periods. Furthermore, steel billets offer excellent weldability, making them suitable for the construction and repair of marine equipment. The ability to weld steel billets together allows for the seamless joining of different components, ensuring structural integrity and reducing the risk of failure. This welding capability facilitates the assembly and maintenance of marine equipment, enabling efficient production processes and cost-effective repairs. In summary, steel billets are essential in the manufacturing of marine equipment due to their strength, durability, versatility, corrosion resistance, and weldability. These qualities make steel billets a preferred choice for producing various marine components, ensuring the reliability, safety, and longevity of the equipment in the demanding marine environment.

- Q: What is the global production and consumption of steel billets?

- Steel billets play a crucial role in the worldwide construction and manufacturing sectors, with their production and consumption being of great significance. When it comes to manufacturing, several countries are major players in the production of steel billets. China, the largest producer of steel globally, contributes significantly to the global steel billet production. Other notable producers include India, Japan, Russia, the United States, and Turkey. These countries have well-established steel industries and infrastructure to support large-scale production. The consumption of steel billets is driven by the demand for steel products in various sectors. The construction and infrastructure development sectors are the primary drivers, as steel is widely used in the construction of buildings, bridges, roads, and other structures. The automotive industry is also a major consumer, utilizing steel billets for manufacturing automobile parts and components. Providing an exact figure for global steel billet production and consumption is challenging due to the ever-changing market dynamics and varying industry reports. However, it is estimated that global steel production exceeded 1.8 billion metric tons in 2020, with a significant portion of this production in the form of steel billets. The consumption of steel billets is closely linked to overall steel demand, which is influenced by economic growth, infrastructure development, industrial activity, and construction projects worldwide. In conclusion, the global production and consumption of steel billets are of great significance, highlighting the importance of steel as a vital material in various industries. The continuous growth in infrastructure development and industrialization globally is expected to further drive the production and consumption of steel billets in the years to come.

- Q: How are steel billets used in the production of structural components?

- Steel billets are used in the production of structural components by being heated and molded into desired shapes such as beams, columns, and plates. These billets serve as the starting material, which is then further processed through rolling, forging, or extrusion to create strong and durable structural components used in various industries such as construction, automotive, and aerospace.

- Q: How do steel billets contribute to the manufacturing of electrical appliances?

- Steel billets play a vital role in the manufacturing of electrical appliances by providing a strong and durable material for various components. Electrical appliances, such as refrigerators, washing machines, and air conditioners, require sturdy structures to withstand constant usage and external forces. Steel billets, which are semi-finished metal products, are used as a raw material in the manufacturing process to create these robust structures. Firstly, steel billets are forged or rolled into different shapes and sizes to create the frames, chassis, and housing of electrical appliances. These components provide the necessary support and protection for the internal parts of the appliances. The strength and stability of steel make it an ideal choice for withstanding the weight and vibrations generated during the operation of electrical appliances. Additionally, steel billets are used to fabricate the motor cores and transformer cores in electrical appliances. Motor cores are essential for converting electrical energy into mechanical energy, while transformer cores are responsible for regulating the voltage in electrical circuits. Steel's magnetic properties, such as high electrical conductivity and low hysteresis loss, make it an excellent choice for these applications, ensuring efficient energy conversion and transmission. Moreover, steel billets are utilized to manufacture heating elements and electrical contacts in appliances like stoves, ovens, and switches. These components require materials that can withstand high temperatures, resist corrosion, and provide excellent electrical conductivity. Steel billets are often alloyed with other metals, such as nickel or chromium, to enhance these properties, making them highly suitable for such applications. In conclusion, steel billets contribute significantly to the manufacturing of electrical appliances by providing a durable and versatile material for various components. The strength, stability, and magnetic properties of steel make it an essential raw material for creating the frames, motor cores, transformer cores, heating elements, and electrical contacts used in these appliances. Thanks to steel billets, electrical appliances can perform reliably and efficiently, meeting the needs and expectations of consumers.

- Q: Can steel billets be used in the production of electrical appliances?

- Steel billets have the potential to be utilized in the manufacturing of electrical appliances. These semi-finished products, commonly employed in the production of diverse steel goods, can be further manipulated and molded into the necessary components for electrical appliances. These components may include casings, frames, brackets, and other structural parts. The utilization of steel offers robustness, longevity, and protection against corrosion, rendering it appropriate for the rigorous demands of electrical appliances. Moreover, steel is readily accessible and cost-efficient, making it a favored option for the production of electrical appliances.

- Q: What are the potential applications of steel billets in the transportation aftermarket?

- Steel billets have a wide range of potential applications in the transportation aftermarket. One of the main uses of steel billets in this industry is for the production of various components and parts for vehicles. These billets can be used to manufacture engine parts, suspension components, steering parts, and other critical components that require strength and durability. Steel billets can also be used in the manufacturing of structural components for vehicles, such as chassis frames and body panels. The high strength and rigidity of steel make it an ideal material for these applications, as it can withstand the stresses and strains experienced during vehicle operation. Furthermore, steel billets can be utilized in the production of wheels and rims for automobiles, motorcycles, and even bicycles. The superior strength and ability to withstand heavy loads make steel billets a preferred choice for wheel manufacturing, ensuring safety and reliability on the road. In addition to vehicle components and parts, steel billets can also be used in the production of rail tracks and infrastructure for railways. The strength and durability of steel make it an ideal material for rail tracks, ensuring safe and efficient transportation of goods and passengers. Overall, the potential applications of steel billets in the transportation aftermarket are vast and diverse. From manufacturing critical vehicle components to building infrastructure for railways, steel billets play a crucial role in ensuring the efficiency, safety, and reliability of transportation systems.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets contribute to the overall safety of a structure by providing a strong and durable material for construction. The high strength and toughness of steel billets make them resistant to external forces such as earthquakes, wind, and heavy loads. Additionally, steel billets have excellent fire resistance, as they do not burn or release toxic gases when exposed to high temperatures. This ensures the structural integrity of the building during a fire. Moreover, steel billets can be easily fabricated into various shapes and sizes, allowing for precise engineering and construction, which further enhances the safety and stability of the structure.

Send your message to us

Prime quality prepainted galvanized steel 615mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords