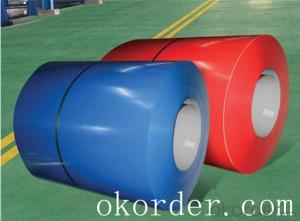

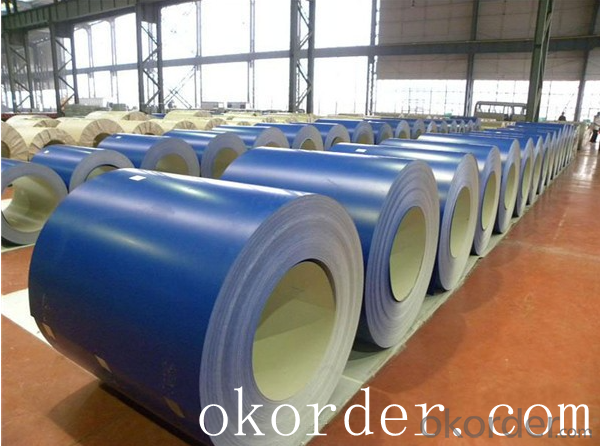

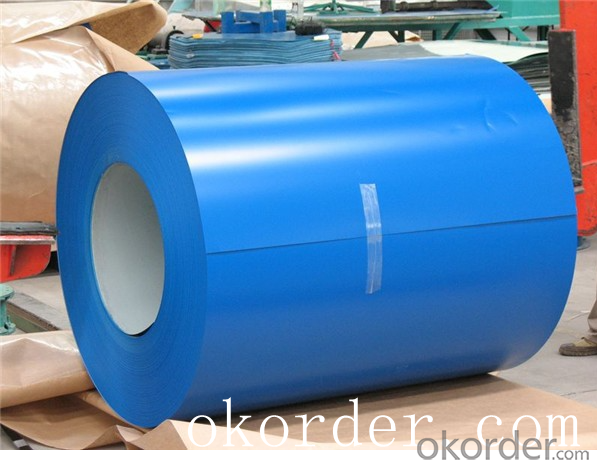

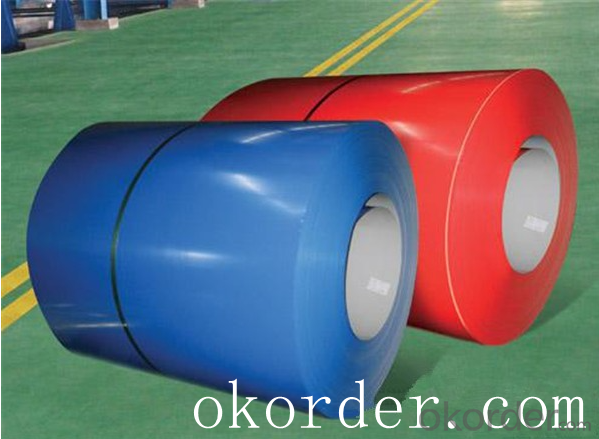

Prime quality prepainted galvanized steel 630mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: How are steel billets used in the production of marine vessels?

- Steel billets serve as a crucial element in the manufacturing process of marine vessels. They are utilized as raw materials for the production of different structural components and parts needed for the vessels. To begin with, the steel billets are melted and cast into diverse shapes and sizes, depending on the specific requirements of the vessel. These billets are commonly converted into plates, beams, channels, and sections, which are essential for the overall structure of the vessel. These steel components are used in the construction of the hull, which is the primary body of the ship responsible for providing the necessary strength and buoyancy. Typically, steel plates and sections made from steel billets are employed in building the hull. These steel components are joined together through welding to create a robust and watertight structure capable of enduring the harsh conditions encountered at sea. Furthermore, steel billets are also employed in the fabrication of other vital parts of marine vessels such as the superstructure, decks, bulkheads, and frames. These components play a crucial role in providing stability, strength, and support to the vessel. Prior to assembly and welding, the steel billets are shaped and sized to fit the requirements of these components. Additionally, steel billets find their usage in the production of machinery and equipment found on board marine vessels. For instance, propulsion systems, engines, and various mechanical components are often crafted from steel billets. These parts are indispensable for the vessel's functionality and ensure the smooth operation of the ship. In conclusion, the significance of steel billets in the production of marine vessels cannot be overstated. They are transformed into various structural components, parts, and machinery that are vital to the construction and functionality of the vessel. Absent steel billets, the production of marine vessels would be impossible, as they provide the necessary strength, durability, and stability required for safe and efficient maritime operations.

- Q: How are steel billets used in the production of automotive components?

- Steel billets are a crucial raw material used in the production of automotive components. In the manufacturing process, steel billets are heated and then forged or rolled into various shapes and sizes to create the desired automotive parts. These billets serve as a starting point for the production of components such as engine blocks, crankshafts, connecting rods, axles, and suspension parts. The high strength and durability of steel make it an ideal material for these critical components, ensuring the safety and performance of automobiles. Once heated, the steel billets are subjected to various shaping processes, such as hot forging or hot rolling. Hot forging involves applying pressure to the heated billet using a die to create the desired shape. This process not only gives the component its final shape but also improves its mechanical properties by aligning the steel's grain structure. Hot rolling, on the other hand, involves passing the heated billet through a series of rolling mills to gradually reduce its thickness and shape it into a specific profile. This process is commonly used for producing long automotive components like axles or suspension parts. After the shaping process, the automotive components undergo additional manufacturing steps like heat treatment, machining, and surface finishing to enhance their strength, precision, and aesthetic appeal. Steel billets offer several advantages in automotive component production. Their excellent mechanical properties, including high strength, toughness, and wear resistance, make them ideal for withstanding the demanding conditions and loads experienced by automotive parts. Additionally, steel's ability to be easily shaped and formed allows manufacturers to create complex and intricate designs, ensuring optimal functionality and performance. In conclusion, steel billets play a vital role in the production of automotive components by providing the raw material that is shaped and formed into various critical parts. The strength, durability, and versatility of steel make it an essential material for ensuring the safety, reliability, and performance of automobiles.

- Q: What are the advantages of using steel billets in the oil and gas industry?

- Using steel billets in the oil and gas industry offers several benefits. Firstly, steel billets are known for their strength and durability. They can withstand extreme temperatures, pressures, and corrosive environments, which are common in the industry. Secondly, steel billets are resistant to corrosion. They are often made from corrosion-resistant alloys or treated with protective coatings, ensuring they can handle corrosive substances and last longer. Thirdly, steel billets are highly versatile. They can be easily shaped into different components, allowing for customization and adaptability to specific projects. Fourthly, steel billets provide excellent safety properties. They are less likely to fail or rupture, reducing the risk of accidents and ensuring personnel and assets are safe. Additionally, although steel billets may have higher upfront costs, their durability and resistance to corrosion result in long-term cost savings. Moreover, steel is widely available and cost-effective to source and produce. Lastly, using steel billets promotes environmental sustainability as steel is highly recyclable. Overall, the advantages of using steel billets in the oil and gas industry contribute to efficient and reliable operations.

- Q: What are the main characteristics of high-quality steel billets?

- The main characteristics of high-quality steel billets include superior chemical composition, uniform and refined microstructure, precise dimensions, and excellent surface quality. Firstly, high-quality steel billets have a superior chemical composition. This means that they are made from carefully selected raw materials and have the right balance of elements to ensure optimal strength, durability, and corrosion resistance. The chemical composition is crucial in determining the overall quality and performance of the steel billets. Secondly, high-quality steel billets have a uniform and refined microstructure. This means that the grains within the steel are evenly distributed and have been properly refined during the manufacturing process. A uniform and refined microstructure enhances the strength and toughness of the steel, making it more resistant to cracking, deformation, and other forms of mechanical stress. In addition, high-quality steel billets have precise dimensions. They are manufactured to strict tolerances, ensuring that they have the correct length, width, and thickness. Precise dimensions are important as they allow for easy and accurate machining, forging, or rolling of the billets into the desired end products. This ensures that the final products made from the billets have consistent and accurate dimensions. Lastly, high-quality steel billets have excellent surface quality. They are free from defects such as cracks, scale, or other surface imperfections. A smooth and clean surface allows for better heat transfer, improved weldability, and enhanced overall appearance of the final products. It also ensures that the billets can be easily inspected and processed without any hindrances. Overall, high-quality steel billets possess superior chemical composition, uniform and refined microstructure, precise dimensions, and excellent surface quality. These characteristics are essential in producing steel billets that meet the highest standards of strength, durability, and reliability, making them suitable for various industrial applications.

- Q: How do steel billets contribute to the manufacturing of aerospace components?

- Steel billets contribute to the manufacturing of aerospace components by serving as the raw material for forging, extrusion, or rolling processes. These billets are heated and shaped into various aerospace components, such as engine parts, landing gear, and structural components. The high strength and durability of steel make it an ideal choice for aerospace applications, ensuring the safety and reliability of the components.

- Q: How are steel billets used in the production of mining machinery?

- Due to their unique properties and versatility, steel billets play a crucial role in the production of mining machinery. These semi-finished metal forms are made from raw iron ore and undergo a series of heating, rolling, and cooling processes to achieve their final shape and properties. In the manufacturing of mining machinery, steel billets are the primary raw material for various important components. Heavy-duty structural parts, such as frames, chassis, and support structures, require high strength and durability to withstand the extreme conditions and heavy loads in mining operations. Steel billets also serve as the foundation for critical functional components like gears, shafts, and axles. These components are vital for the proper functioning and control of mining machinery, as they transmit power and facilitate movement. Steel billets offer excellent machinability, allowing them to be easily shaped into the complex geometries required for these components. Moreover, steel billets are used to produce wear-resistant parts and components that can withstand constant abrasion, impact, and wear. Cutting edges, buckets, and crusher liners are examples of such components. Steel billets are often alloyed with elements like manganese or chromium to enhance their hardness, toughness, and resistance to wear. In the production of mining machinery, steel billets are also utilized for hydraulic components and systems. Hydraulic cylinders, valves, and pumps are essential for the operation and control of mining equipment. Steel billets provide the necessary strength and integrity to withstand high-pressure hydraulic systems, ensuring reliable and efficient performance. In summary, steel billets are indispensable in the production of mining machinery. They are used to manufacture various structural, functional, and wear-resistant components that are vital for the reliable and efficient operation of mining equipment. The unique properties of steel billets, including their strength, durability, and machinability, make them an ideal choice for withstanding the demanding conditions encountered in mining operations.

- Q: What are the potential applications of steel billets in the mining industry?

- Steel billets have a wide range of potential applications in the mining industry. Firstly, steel billets can be used in the construction of mining equipment and machinery. These billets can be shaped and welded to form various components such as frames, supports, and chassis for heavy mining machinery. The strength and durability of steel make it an ideal material for withstanding the harsh conditions and heavy loads encountered in mining operations. Secondly, steel billets can be utilized in the fabrication of conveyor belts, which are essential for the transportation of bulk materials in mines. The high tensile strength of steel ensures that the conveyor belts can withstand the weight of the material being transported, as well as the continuous movement and impact from the mining process. Additionally, steel billets can be employed in the construction of underground support systems, such as mine shafts and tunnels. These structures require strong and reliable materials to ensure the safety of workers and the integrity of the mining operation. Steel billets can be used to manufacture support beams, rods, and plates, providing the necessary stability and reinforcement. Moreover, steel billets can be used in the production of wear-resistant components, such as grinding balls and liners, which are crucial in mineral processing. These components are used in grinding mills to crush and grind the ore, and the abrasion-resistant properties of steel make it a suitable material for this application. By using steel billets, mining companies can enhance the efficiency and longevity of their mineral processing operations. Overall, the potential applications of steel billets in the mining industry are extensive. From equipment manufacturing and conveyor belt fabrication to underground support systems and wear-resistant components, steel billets play a vital role in improving the productivity, safety, and efficiency of mining operations.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- Billet is the product of molten steel made by steelmaking furnace. After casting, the billet can be divided into two kinds: casting blank and continuous casting billet. At present, the casting process has been basically eliminatedRefers to the use of reinforced and prestressed concrete with steel reinforced concrete, the cross section is circular, sometimes square with rounded corners. Including round bars, ribbed steel bars, steel torsion bar.

- Q: What are the potential applications of steel billets in the telecommunications industry?

- The telecommunications industry benefits greatly from the wide range of potential applications offered by steel billets. A key application lies in the construction of telecommunication towers, where steel billets serve as the foundation for manufacturing the structural components. These components provide the necessary strength and durability to support the weight of antennas and other equipment. Moreover, steel billets play a vital role in the production of transmission line hardware, including pole line fittings, brackets, and clamps. These components are crucial for ensuring the stability and reliability of telecommunication lines during installation and maintenance. Furthermore, steel billets are essential in the manufacturing of enclosures, both underground and overhead, that protect telecommunication cables from external factors such as moisture, heat, and physical damage. This protection guarantees uninterrupted communication. In addition, steel billets are utilized in the production of telecommunication equipment cabinets and racks, which provide a secure and organized space for housing network equipment, such as servers, switches, and routers. The strength and rigidity of steel billets make them ideal for supporting heavy equipment and protecting against environmental hazards. Lastly, steel billets find application in the construction of telecommunication infrastructure, including base stations and equipment shelters. These structures require robust materials to withstand harsh weather conditions and provide a stable foundation for the installation of telecommunications equipment. In conclusion, the versatility and durability of steel billets make them ideal for various aspects of the telecommunications industry, from tower construction to cable enclosures and equipment cabinets. Steel billets provide the necessary support and protection for telecommunication infrastructure and equipment.

- Q: What are the main factors affecting the hardenability of stainless steel billets?

- The hardenability of stainless steel billets, or the ability of the material to be hardened through heat treatment, is influenced by several factors. 1. Alloy composition: The composition of stainless steel, particularly the content of elements such as carbon, chromium, nickel, and molybdenum, plays a significant role in its hardenability. Higher carbon content generally improves hardenability, while alloying elements like chromium and nickel enhance the corrosion resistance of stainless steel but may reduce its hardenability. 2. Grain size: The grain size of stainless steel billets affects the rate and depth of hardening. Finer grain structures tend to have better hardenability compared to coarser grain structures. This is because smaller grains allow for more uniform distribution of carbon and alloying elements, resulting in improved hardening response. 3. Heat treatment conditions: The specific heat treatment process used, including heating and cooling rates, soaking time, and quenching media, can significantly impact the hardenability of stainless steel billets. Proper control of these parameters is crucial to achieving the desired hardness and mechanical properties. 4. Cooling rate: The cooling rate during the quenching process is a critical factor in determining the hardenability of stainless steel. Rapid quenching, such as water or oil quenching, promotes martensitic transformation and greater hardness. Slower cooling rates, such as air cooling, result in a softer and less hardened structure. 5. Cross-sectional thickness: The thickness of the stainless steel billets also affects their hardenability. Thicker sections tend to have lower hardenability due to slower heat transfer rates during the quenching process. Thinner sections, on the other hand, can achieve higher hardness levels due to faster cooling rates. 6. Prior microstructure: The initial microstructure of the stainless steel billets, such as whether it is in the annealed or cold-worked condition, can influence hardenability. Cold work can introduce dislocations and grain boundaries, which may hinder the diffusion of carbon and alloying elements during heat treatment, resulting in reduced hardenability. Considering these factors, manufacturers and engineers must carefully select stainless steel grades and tailor the heat treatment process to achieve the desired level of hardenability and mechanical properties in stainless steel billets.

Send your message to us

Prime quality prepainted galvanized steel 630mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords