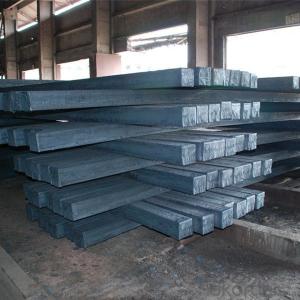

Prime Mild Steel Bar Carbon Steel Billets from Manufactures China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16210 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How do steel billets contribute to the marine industry?

- Steel billets are an essential component in the marine industry as they serve as the raw material for the manufacturing of various marine structures and equipment. These billets are used to produce ship hulls, propeller shafts, offshore platforms, and other critical components. The high strength and durability of steel make it ideal for withstanding the harsh conditions of the marine environment, ensuring the safety and reliability of marine vessels and structures. Additionally, steel billets can be easily shaped and welded, allowing for the construction of complex marine structures. Overall, steel billets play a crucial role in supporting the growth and development of the marine industry.

- Q: How is the strength of steel billets measured?

- The strength of steel billets is typically measured using a tensile test, where a sample is subjected to pulling forces until it fractures. The maximum force applied during the test is recorded and used to determine the strength of the steel.

- Q: How are steel billets used in the manufacturing of railway wagons?

- Steel billets are used in the manufacturing of railway wagons as they serve as the raw material for various components such as frames, side panels, and undercarriages. These billets are first heated and then shaped into the desired form through processes like rolling or forging. The resulting components are strong, durable, and able to withstand the rigorous demands of railway transportation, ensuring the safety and reliability of the wagons.

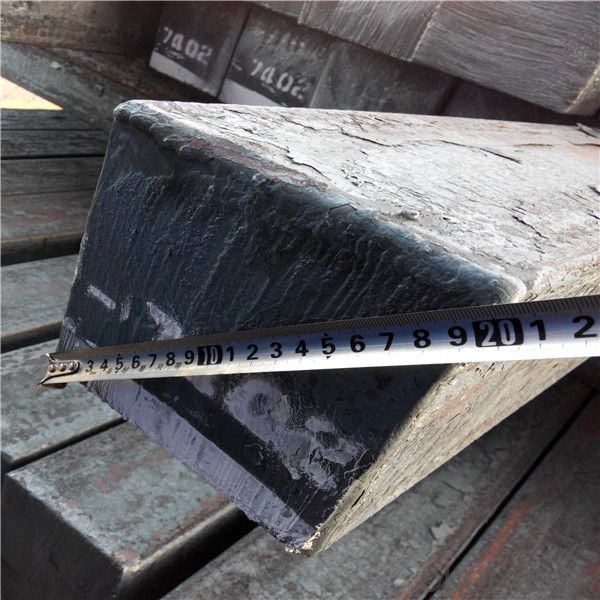

- Q: What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet vary depending on its application and the specific requirements of the industry. However, common dimensions for steel billets range from 100mm to 300mm in width and 100mm to 400mm in height, with lengths typically ranging from 3 to 6 meters.

- Q: Can steel billets be used in the production of appliances?

- Yes, steel billets can be used in the production of appliances. Steel billets are semi-finished products that are typically used for further processing into various shapes and sizes. In the case of appliances, steel billets can be used as the raw material for manufacturing components such as frames, panels, and other structural parts. Steel is a versatile and durable material that offers strength, stability, and resistance to corrosion, making it suitable for use in appliances that require robust construction. Additionally, steel can be easily molded and shaped to meet the specific design requirements of different appliances, making it a preferred choice in the manufacturing process.

- Q: What are the different heat treatment processes used for steel billets?

- There are several heat treatment processes used for steel billets, each serving a specific purpose and resulting in different mechanical properties. These processes include annealing, normalizing, quenching, tempering, and case hardening. Annealing is a process where steel billets are heated to a specific temperature and then slowly cooled in order to soften the material and improve its ductility. This process helps to reduce internal stresses and homogenize the microstructure of the steel. Normalizing involves heating the steel billets to a temperature above the critical point and then allowing them to cool in still air. This process is used to refine the grain structure and improve the mechanical properties, such as strength and toughness. Normalizing also helps to reduce any residual stresses and improve the machinability of the steel. Quenching is a rapid cooling process that involves immersing the heated steel billets into a quenching medium, such as water or oil, to achieve a high degree of hardness. This process results in a hardened and brittle material, which is often followed by a tempering process to reduce the brittleness and improve the toughness. Tempering is the process of reheating the quenched steel billets to a specific temperature and then allowing them to cool slowly. This process helps to relieve any residual stresses and improve the toughness and ductility of the material. Tempering also helps to reduce the hardness achieved during the quenching process, resulting in a material with a balance of strength and toughness. Case hardening is a heat treatment process used to selectively harden the surface layer of the steel billets, while maintaining a softer and more ductile core. This is achieved by introducing carbon or nitrogen into the surface layer of the material, either through carburizing or nitriding processes. Case hardening improves the wear resistance and surface hardness of the steel, making it suitable for applications where high surface hardness is required. Overall, these different heat treatment processes for steel billets provide a range of mechanical properties and allow for customization based on the specific requirements of the application. Each process has its own advantages and limitations, and the selection depends on factors such as the desired mechanical properties, the steel grade, and the intended application.

- Q: What is the difference between steel and billet in the process?

- Square is a square steel hollow, with iron produced; but it is a square steel billet is generally solid, forging or casting molding.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include hot rolled, cold rolled, and coated finishes.

- Q: What are the factors that affect the mechanical properties of steel billets?

- There are several factors that affect the mechanical properties of steel billets. 1. Chemical composition: The chemical composition of steel, including the levels of carbon, manganese, silicon, and other alloying elements, plays a significant role in determining its mechanical properties. These elements affect the strength, hardness, and ductility of the steel billets. 2. Heat treatment: The heat treatment process, including the temperature and duration of heating and cooling, can greatly influence the mechanical properties of steel billets. Heat treatment techniques such as annealing, quenching, and tempering can be used to enhance the hardness, toughness, and overall strength of the steel. 3. Microstructure: The microstructure of steel, which is determined by factors such as cooling rate and alloying elements, greatly influences its mechanical properties. The presence of different phases, such as ferrite, pearlite, and martensite, affects the strength, ductility, and toughness of the steel billets. 4. Grain size: The size and distribution of grains in the steel billets can impact their mechanical properties. Finer grain sizes are generally associated with improved strength and toughness, while larger grain sizes may result in reduced mechanical properties. 5. Processing conditions: The processing conditions during the production of steel billets, such as the temperature and rate of deformation, can affect their mechanical properties. Factors such as rolling, forging, and extrusion can influence the grain structure and overall mechanical behavior of the steel. 6. Surface condition: The surface condition of steel billets, including the presence of defects such as cracks, voids, or surface contamination, can have a significant impact on their mechanical properties. Surface defects can act as stress concentration points and reduce the overall strength and integrity of the steel. 7. Environmental factors: Environmental conditions, such as temperature, humidity, and exposure to corrosive substances, can affect the mechanical properties of steel billets. Corrosion can lead to reduced strength and structural integrity, while high temperatures can cause softening or thermal degradation of the steel. It is important to consider these factors when designing and manufacturing steel billets to ensure that the desired mechanical properties are achieved for specific applications.

- Q: What is the role of steel billets in the manufacturing of storage systems?

- Steel billets play a crucial role in the manufacturing of storage systems as they serve as the raw material for the production of various steel components used in these systems. These billets are heated, rolled, and shaped to create beams, columns, and other structural elements that provide strength and stability to the storage systems. Additionally, steel billets can be further processed to create shelves, racks, and other storage components, ensuring durability and reliability in the overall design.

Send your message to us

Prime Mild Steel Bar Carbon Steel Billets from Manufactures China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16210 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords