Prepainted rolled steel Coil for Construction Roofing use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

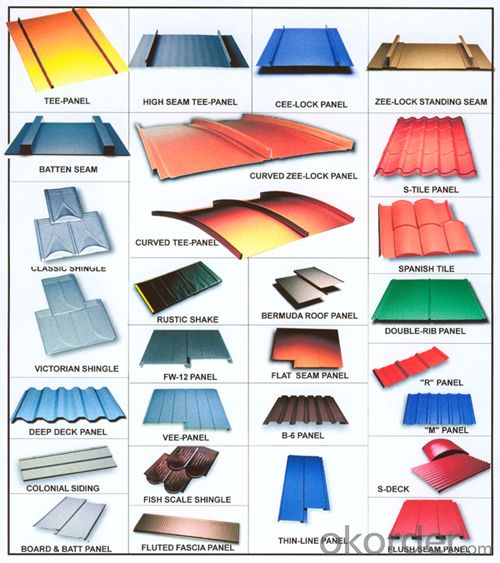

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Apparently, this has to do something with electrochemical cells.

- Steel wool is a mild abrasive. I don't know what it is you are cleaning, but it is probably to remove any coating or oxidisation from the metal. Maybe you are using a metal for an electrode (perhaps a steel nail pushed into a lemon?).

- Q:Is there a type of spray paint that would work on Stainless steel?That would also be permenant or at least make it through a wash or two?

- I've also learned something today! Good luck and have fun!

- Q:Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- depends on the amount on nickel used in the manufacturing but mostly yes

- Q:How are steel coils protected during storage and transportation?

- Steel coils are typically protected during storage and transportation through various methods such as applying anti-corrosion coatings, wrapping them in protective materials like plastic or paper, and securing them with strapping or banding to prevent damage or movement.

- Q:Can steel coils be coated with anti-tampering materials?

- Yes, steel coils can be coated with anti-tampering materials. These materials provide an additional layer of protection against tampering and unauthorized access to the steel coils.

- Q:How do steel coils contribute to the automotive manufacturing sector?

- Steel coils are essential in the automotive manufacturing sector as they are used to produce various components such as body parts, frames, and suspension systems. The high strength and durability of steel coils make them ideal for ensuring the safety and structural integrity of vehicles. Additionally, steel coils are easily moldable, allowing manufacturers to create complex shapes and designs, contributing to the overall aesthetics and functionality of automobiles.

- Q:How are steel coils affected by global trade policies?

- Steel coils are significantly affected by global trade policies as they are subject to various tariffs, quotas, and trade restrictions imposed by different countries. These policies can impact the cost, availability, and competitiveness of steel coils in the international market. Changes in trade policies can lead to fluctuations in demand and supply, impacting the prices and trade volumes of steel coils.

- Q:How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process known as galvanization. This involves applying a protective layer of zinc onto the surface of the steel coils. The zinc acts as a barrier, preventing the steel from coming into contact with moisture and oxygen, which are the main causes of corrosion. This coating not only provides excellent corrosion resistance but also enhances the durability and longevity of the steel coils.

- Q:What are the different methods of roll forming steel coils?

- There exists a variety of techniques for roll forming steel coils, each possessing distinct features and uses. Some prevalent methods encompass: 1. Conventional Roll Forming: This technique, widely employed, involves gradually shaping a continuous steel strip into the desired profile by passing it through a series of rollers. It offers high precision and repeatability, making it ideal for manufacturing intricate shapes and profiles. 2. Pre-Punch and Cut: With this method, the steel strip is pre-punched with holes or slots before undergoing roll forming. This facilitates easier cutting and shaping during the forming process, enhancing efficiency and reducing waste in specific applications. 3. Post-Punch and Cut: Similar to pre-punching and cutting, this method adds holes or slots after the roll forming process. It provides greater flexibility in creating customized shapes and designs since the holes can be precisely placed as required. 4. Post-Forming: On certain occasions, the steel strip is initially roll formed into a basic shape or profile, which is then further manipulated or formed. This approach allows for additional customization and enables the creation of more intricate geometries. 5. Progressive Roll Forming: This technique involves continuously passing the steel strip through a series of rollers, with each roller gradually adding a distinct feature or forming a specific part of the final profile. Progressive roll forming is commonly utilized for lengthy, continuous profiles with repetitive shapes. 6. Incremental Roll Forming: In this method, the steel strip is incrementally shaped by means of small movements of the rollers. It provides greater flexibility in shaping complex profiles and proves particularly useful for producing prototypes or low-volume production runs. Ultimately, the selection of a roll forming method depends on the specific requirements of the application, such as the desired shape, complexity, precision, and production volume. Each method presents its own advantages and limitations, and manufacturers typically choose the most suitable technique based on these factors.

- Q:i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Bench grinder, Dremel Hand Grinder

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted rolled steel Coil for Construction Roofing use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords