prepainted Rolled steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

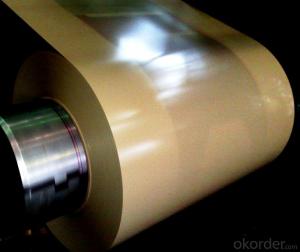

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: My boyfriend says he has balls of steel.

- it is extra of a euphemism than actuality. somewhat the testicles are somewhat gentle and may even herniate or rupture; it somewhat is why they cover those balls of steel with athletic cups earlier they actually take the sector.

- Q: Can steel coils be customized?

- Yes, steel coils can be customized to meet specific requirements such as size, shape, thickness, and surface finish. Customization can be done through processes like cutting, slitting, shaping, and coating to ensure that the steel coils are tailored to the desired specifications.

- Q: How are steel coils used in the manufacturing of railway tracks?

- Steel coils are used in the manufacturing of railway tracks as they are processed into long, continuous lengths of steel rails. These coils are first uncoiled and then passed through a series of machines that shape, cut, and weld them together to form the required lengths and profiles of railway tracks.

- Q: The Iron and Steel Corporation of Great Britain (1949) or Iron and Steel Bill was introduced in 1949 during the Labour post-war Government.What was it introduced for?

- To create iron and steel.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Rust is the process of steel oxidizing when in contact with oxygen, this reaction can be much fast if certain components are present, such as wet air or water. However, if the paint completely isolates the steel from the environment, the encompassed steel will never rust as long as paint shields it. Aluminum corrodes but it does not rust. Rust refers only to iron and steel corrosion. Aluminum is actually very prone to corrosion. However, aluminum corrosion is aluminum oxide, a very hard material that actually protects the aluminum from further corrosion. Aluminum oxide corrosion also looks a lot more like aluminum, so it isn't as easy to notice as rusted iron.

- Q: What are the common methods of transporting steel coils?

- Depending on factors such as coil size, weight, destination, and specific handling requirements, there are various common methods for transporting steel coils. These methods include: 1. Short-distance transportation: For short distances, steel coils are often transported using flatbed trucks. These trucks have a flat trailer bed that allows for easy loading and unloading of the coils. To prevent movement during transit, the coils are secured and strapped down. 2. Long-distance transportation: Rail transport is commonly preferred for longer distances due to its cost-effectiveness and efficiency. Specially designed railcars, known as coil cars or gondola cars, are used to securely hold the coils in place. This method is particularly advantageous for large quantities of steel coils. 3. International or long-distance transport: Shipping by sea is a common method for transporting steel coils internationally or over long distances. The coils are loaded into specialized shipping containers with internal cradles to prevent movement and damage during transit. These containers are then loaded onto cargo ships. 4. Waterway transportation: In regions with navigable waterways, barges can be used to transport steel coils. Similar to ocean freight, the coils are loaded into specially designed containers or barges with cradles to secure them during transport. Barge transport offers an economical and environmentally friendly option, especially for inland waterway transportation. 5. Combined transportation: In certain cases, a combination of different transportation modes, known as intermodal transport, may be used. For instance, steel coils can be initially transported by truck and then loaded onto railcars for long-distance transport. This approach allows for the optimization of cost and efficiency by utilizing the advantages of different transportation modes. It's important to note that the specific method of transporting steel coils can vary based on various factors, including coil size, weight, destination, and any specific handling requirements.

- Q: What is the thickness range of steel coils?

- The thickness range of steel coils varies depending on the specific application and industry. However, generally speaking, steel coils can have a thickness range from as thin as 0.005 inches (0.13 mm) to as thick as 0.5 inches (12.7 mm) or more.

- Q: What is the role of steel coils in the electrical industry?

- The role of steel coils in the electrical industry is significant as they serve multiple purposes in various applications. Steel coils are used as components in transformers, which are essential for power distribution and voltage regulation. These coils are responsible for transferring electrical energy from one circuit to another, allowing for efficient transmission of electricity across long distances. Additionally, steel coils are utilized in the production of electric motors and generators. They are wound around the stator and rotor to create magnetic fields, which enable the conversion of electrical energy into mechanical energy and vice versa. This process is crucial in various industries, including automotive, manufacturing, and renewable energy sectors. Steel coils also play a role in the production of electrical cables and wiring. They are used to provide strength, durability, and protection to the conductive copper or aluminum wires within the cables. These coils are responsible for maintaining the structural integrity of the cables, ensuring safe and efficient transmission of electricity. Furthermore, steel coils find application in electrical equipment such as solenoids and relays, where they help create magnetic fields to control the flow of electrical current. They are also used in various electrical appliances, including refrigerators, air conditioners, and televisions, where they act as essential components in the functioning of these devices. In summary, steel coils have a vital role in the electrical industry. They are used in transformers, motors, generators, cables, and various electrical equipment, contributing to the efficient distribution, conversion, and transmission of electrical energy.

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- This Site Might Help You. RE: Why would a knife be made from surgical steel? Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and...

- Q: I want a stainless steel refrigerator that doesn't leave fingerprints and I'm looking on Lowe's website but they have too many choices and i don't have a clue what they are. The have stainless, stainless look, stainless steel, monochromatic satina, and monochromatic stainless steel. Can anyone tell me what the heck those mean? lol

- Stainless Look vs Stainless in refrigerators usually refers to true Stainless Steel versus Satina. There's pluses and minuses both ways actually. With true Stainless, you have the exact match to the rest of the kitchen (because Satina is only used on refrigeration), but it is more prone to fingerprints, and is not magnetic. The Satina finish has a good look when not directly near a Stainless appliance, and does not show fingerprints and will accept magnets, but is not an exact match to stainless. My usual recommendation is that if you have a kitchen full of Stainless products, stick with the true Stainless Steel. If the refrigerator is more isolated, or is the only thing you want to have a Stainless look, you may want to consider Satina. If you put a lot of magnets on the refrigerator, I'd also recommend to go Satina. And since you don't want fingerprints, the Satina steel might come to your liking.

Send your message to us

prepainted Rolled steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords