BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

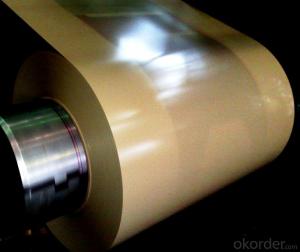

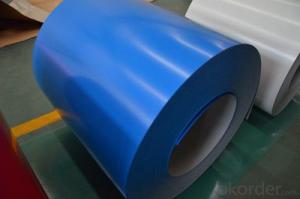

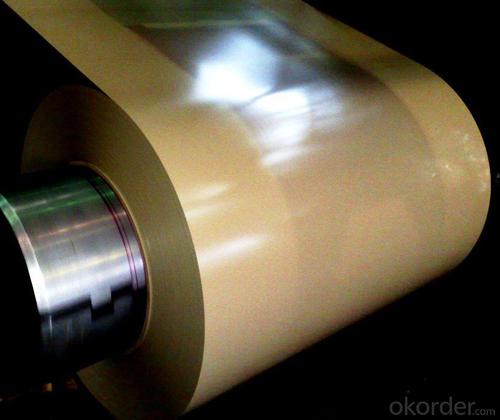

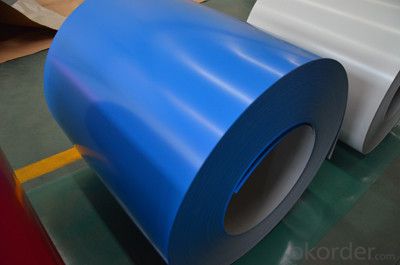

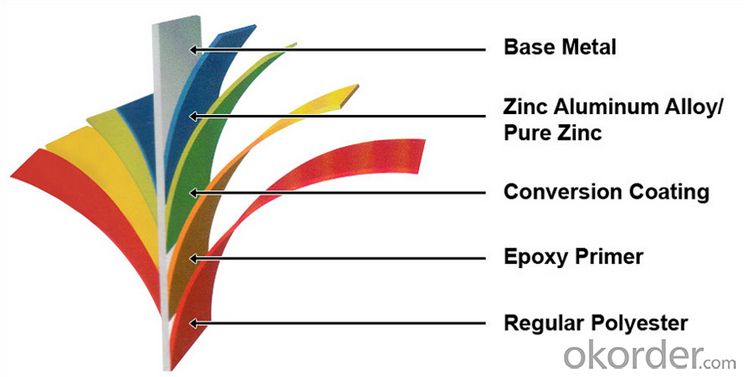

Structure of BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

Description of BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

Cold Rolled Steel is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers.Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities.The Cold Rolled Steel is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel is further reduced, its strength and hardness both increase, but its ductility decreases.After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility.

Main Feature of BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

Base mental: Hot galvanized steel,SGCC,SPCC,SPHC, DX51D+Z, Q195,etc

Quality: CQ,DQ,DX51D

Lifespan: 10-15 years

Applications of BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

Specifications of BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2.Are the products tested before shipping??

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: i found a similar question asking what metals were in stainless steel but i don't know if they are the same.... they probably aren't.

- steel is iron with a little bit of carbon mixed in. how much carbon determines the hardness of the steel. stainless steel is the same mostly, it has nickle and chromium added in to make it corrosion resistant.

- Q: What are steel coils?

- Steel coils are long, flat sheets of steel that have been wound into a coil shape. They are used in various industries for manufacturing purposes, such as in the automotive, construction, and appliance industries. Steel coils are typically made from carbon steel and are commonly used for applications that require strength and durability.

- Q: When steel is cast, does it become weaker/more brittle or anything of this nature? what are the side effects of steel casting on the steel itself?How can you correct these?

- It contains too many air bubble spacing and too many impurity that make it easily to be broken apart. Melt it down again with high heat to remove most impurity, after this process,it becomes iron.

- Q: steel structure

- Disadvantages Of Steel

- Q: What are the dimensions of steel coils used in the structural component industry?

- The dimensions of steel coils used in the structural component industry can vary depending on the specific application and requirements. However, some common dimensions for steel coils used in this industry include a width ranging from 600mm to 2000mm and a thickness ranging from 0.25mm to 10mm. The weight of these coils can also vary, typically ranging from a few kilograms to several tonnes. Additionally, the length of the steel coils can be customized to meet the specific needs of the structural component industry, with common lengths being 2000mm, 2500mm, and 3000mm. It is important to note that these dimensions are not exhaustive and can vary based on the specific product and manufacturer.

- Q: How hot does steel have to get before it will melt?

- Type your query into Yahoo! Search or other search engines to get the answer: It depends, since steel usually has different metals added for various properties (strength, corrosive resistance, etc.)

- Q: What are the common methods of testing the strength of steel coils?

- Steel coils can be tested for strength using various methods. Tensile testing is one such method, which involves applying tension to the coil until it breaks. This test provides information about the coil's ability to withstand force and its tensile strength. It also reveals details about its yield strength and elongation properties. Another common method is hardness testing, which determines the steel's resistance to indentation or scratching. Different techniques like Rockwell, Brinell, or Vickers tests are utilized to measure hardness. This test helps determine the steel's ability to resist wear or deformation. To evaluate the coil's ductility and flexibility, bend testing is performed. The coil is bent to a specific angle and checked for any signs of cracking or fracturing. Bend testing assesses the material's capacity to withstand bending or forming procedures without failure. Additional methods of testing include impact testing, where controlled impacts are applied to assess the coil's resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods used may vary depending on the intended application and industry standards. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can also be employed to detect internal defects or flaws in steel coils without causing any damage.

- Q: What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include emissions of greenhouse gases, such as carbon dioxide, during the process of extracting and processing raw materials like iron ore and coal. Additionally, the production of steel coils requires a significant amount of energy, contributing to the depletion of natural resources and increased carbon emissions. The wastewater generated during steel production can also contain pollutants, which may harm aquatic ecosystems if not properly treated. Furthermore, the disposal of steel coil waste, such as slag and other by-products, can pose challenges in terms of proper handling and potential contamination of soil and water sources. Overall, steel coil production has substantial environmental impacts that demand sustainable practices and mitigation measures.

- Q: I would like to build steel galvanization plant.

- How big of a kettle do you want to go with? A small 6-10 foot kettle would work fine for spinner work (small parts ran in baskets) but if you want to handle large beams and so forth you will need to have at least a 25 foot or longer kettle. You will need tanks for caustic,acid,rinsing,and preflux solutions. If you go with sulfuric acid it will have to be heated. The caustic and flux tanks need to be heated in any case.You will also need a bag house to control smoke coming off the kettle. First you should look into permits such to see if you can actually build this plant. Galvanizing is nasty work and the laws and regs are strict. Former Kettleman

- Q: What are the weight ranges of steel coils?

- The weight ranges of steel coils can vary widely depending on the specific type and dimensions of the coil. However, typical weight ranges for steel coils can range from a few hundred kilograms to several tons.

Send your message to us

BMP Z35 PPGI Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords