BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 125 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

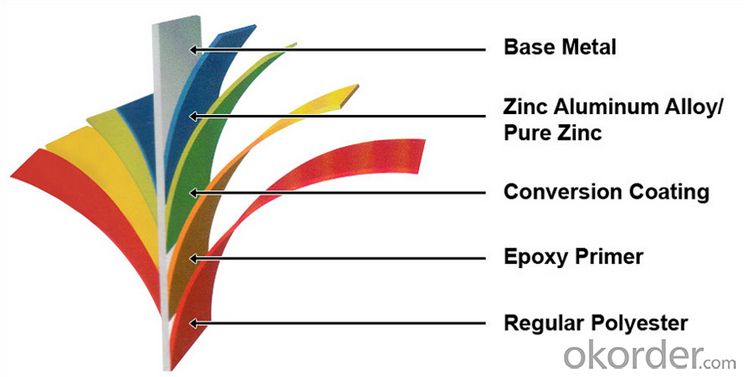

Structure of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Description of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Applications of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door of garage\Roller shutter door\Persian blinds\Cabana and so on.Indoor: Door\Isolater\Frame of door\Light steel structure of house\\Folding screen\Ceiling\Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2. Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the manufacturing of storage systems?

- Due to their durability, strength, and versatility, steel coils are an indispensable element in the production of storage systems. Typically made from high-quality steel, these coils are formed by rolling the steel into a coil shape. Within the manufacturing process of storage systems, steel coils serve multiple functions. Primarily, they are utilized in the construction of shelves, racks, and frames. These components offer the necessary structural support to hold and arrange items within the storage system. The robustness of the steel coils guarantees that the storage system can endure heavy loads and maintain stability over time. Furthermore, steel coils are employed in the fabrication of accessories for storage systems, such as brackets, hooks, and dividers. These accessories provide additional functionality and customization options, enabling users to optimize their storage space according to their specific requirements. Moreover, steel coils often serve as the material for doors and panels in storage systems. These coils are molded and shaped to create sturdy and secure doors that offer convenient access to the stored items while maintaining the overall integrity of the system. These doors can be designed with various locking mechanisms to enhance security and prevent unauthorized access. Additionally, steel coils are crucial in the production of mobile storage systems. These systems, such as mobile shelving units or compactors, are designed to maximize storage capacity in limited space. The flexibility and versatility of steel coils allow for the creation of movable components that can be easily adjusted and reconfigured to accommodate changing storage requirements. In summary, steel coils play a vital role in the manufacturing of storage systems, providing the necessary strength, durability, and versatility required for these structures. Whether utilized for shelves, accessories, doors, or mobile systems, steel coils ensure that storage systems are reliable, secure, and efficient in organizing and storing various items.

- Q: Can steel coils be coated with decorative designs?

- Yes, steel coils can be coated with decorative designs. This can be achieved through various methods such as painting, printing, or applying specialized coatings. The decorative designs can enhance the aesthetic appeal of the steel coils and be customized according to specific requirements.

- Q: How are steel coils protected against fire and heat?

- Steel coils are typically protected against fire and heat through various methods such as fire-resistant coatings, fire blankets, water-based sprays, or the use of fire-resistant barriers or walls in the storage area. Additionally, fire detection and suppression systems, such as sprinkler systems, are often installed to quickly extinguish any potential fire.

- Q: How are steel coils used in the manufacturing of steel drums?

- Steel coils are used in the manufacturing of steel drums by being shaped and welded into the cylindrical body of the drum. The coils are unrolled and cut to the desired length, then formed into a circular shape and welded together to create a seamless drum.

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal/Steel. :)

- Q: I know that mild steel is more brittle than cast iron....but that is all.......please help??Thank you in advance......Ruby:D

- This Site Might Help You. RE: what is the diiferent in composition between mild steel and cast iron? I know that mild steel is more brittle than cast iron....but that is all.......please help? Thank you in advance......Ruby :D

- Q: I am thinking of buying a stainless steel necklace, but I need to know if it will discolor. My brothers ring turned brown, but he forgot what kind of metal it was. Also answer if I can wear it in the shower because I wear my other necklace in it.

- I would say don't wear it in the shower because it will tarnish and it could rust.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they serve as the core material for transformers and inductors. These coils are wound with copper wire to create electromagnetic fields necessary for the functioning of various electrical devices.

- Q: is it much difference between 1095 and 1080,,,1065,,,1060 or even 1045 steel?please help and thanks!

- In okorder /

- Q: My uncle got me some new 'Nam style jungle boots at the px at Fort Worth JSB, and he told me that back in Vietnam, they used to issue guys steel sole boots, that had a sole reinforced with a steel plate, as punji stick d-fence. Is this true, it sounds logical, but I can't figure out how a steel plate in the sole would work. My uncle is kind of a BS'er, plus he wasn't even in Vietnam, much less the Infantry, much less combat, but he was in USAF at the time.

- The issue of steel soled boots in Vietnam did actually happen. The steel plate is in the mid-sole, to prevent punji sticks (or other sharp objects) from penetrating the boot if you stepped down on them. These bamboo or metal spikes - often coated with human excrement - were placed in shallow (camouflaged) pits dug in the ground or sometimes under water at places where you'd ford a stream. Quite apart from the physical injury from stepping on one, there was a high risk of serious infection from what they were coated with. Originally the steel plate was issued as an insole to go inside but that give the soldiers blisters, so later the boots were manufactured with it as part of the sole. Steel toe-cap boots containing a mid-sole plate are sold today for use by builders and construction workers who have a similar risk of stepping on nails, screws, glass, etc.

Send your message to us

BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 125 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords