BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

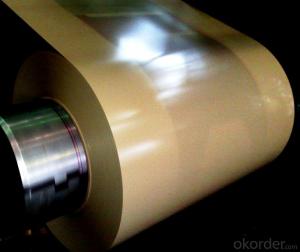

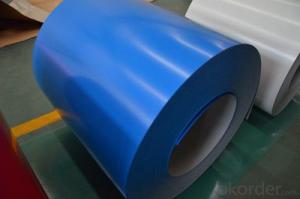

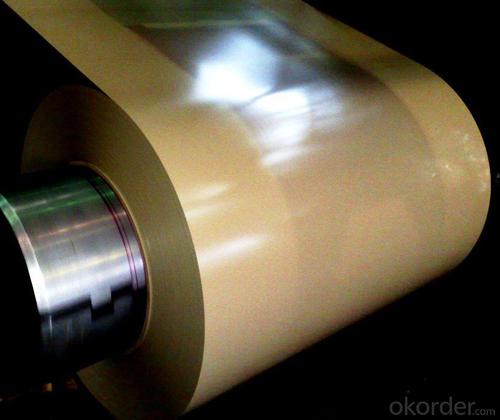

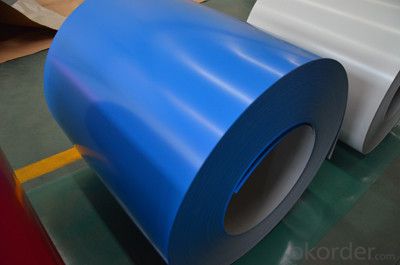

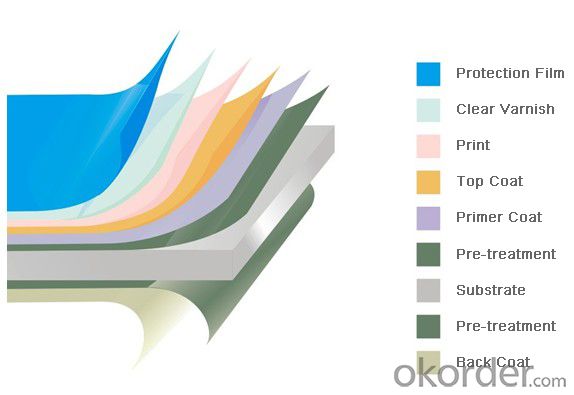

Structure of BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

Description of BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method), and after roasting and cooling.

Main Feature of BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight:4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

Applications of BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

If the yield point is not pronounced, the value applies to R p0.2 ; if the yield point is pronounced, the value applies to R el . When the thickness is less than or equal to 0.7 mm and greater than 0.5 mm, the minimum value for elongation is reduced by 2 units. For a thickness less than or equal to 0.5 mm, the minimum value is reduced by 4 units.it is ideal for a wide range of applications, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

Specifications of BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 5000MT per month |

MOQ | 100MT |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2.Are the products tested before shipping??

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.Why choose us?

ISO system

SGS and BV audited company.

Industry experience over 10 years.

Management systems-internal software

Finished product inventory-more than 500 tons.

Raw material inventory -over 800 mertic tons.

Shipment of goods -more than 30 countries worldwide.

We have the most convenient transport and prompt delivery.

We offer competitive price with best service.

We have high technical production line with top quality products.

We have win high reputation based on best quality products.

- Q: 3 bedroom rambler with attached garage. A bad hail storm in May damaged my white siding and roof. I am concerned insurance adjustThanks much.er will not give me replacement value for steel siding. Any one know the cost and where to buy in Minnesota.

- I'm not sure of the cost but from experience having bought steel siding instead of vinyl for my home, if you can afford the difference it is well worth your money..I've had it for 25 years and it does hold up much better than vinyl!

- Q: How are steel coils inspected for damage during transportation?

- Steel coils are inspected for damage during transportation through various methods such as visual inspections, magnetic particle testing, ultrasonic testing, and dimensional checks.

- Q: When steel is cast, does it become weaker/more brittle or anything of this nature? what are the side effects of steel casting on the steel itself?How can you correct these?

- It contains too many air bubble spacing and too many impurity that make it easily to be broken apart. Melt it down again with high heat to remove most impurity, after this process,it becomes iron.

- Q: What are the factors influencing the price of steel coils?

- The factors influencing the price of steel coils include the cost of raw materials, such as iron ore and coal, as well as energy prices, transportation costs, labor wages, and market demand. Additionally, exchange rates, trade policies, government regulations, and global economic conditions can also impact steel coil prices.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various products. The coils are typically processed and transformed into different shapes, such as sheets, strips, or wires, which are then used to create a wide range of items like appliances, furniture, automotive components, and construction materials. The durability and strength of steel make it an ideal choice for consumer goods, ensuring long-lasting and reliable products for consumers.

- Q: I just got my Daewoo K2 in 5.56 and i know they are tough and reliable but how well will it fair with steel rounds. I know shooting brass is better for any gun but what kind of extra wear and tear would i be looking at with shooting steel. Also what about reloading steel. Is it recomended. I would not even be asking this but steel is far cheaper than brass ammo, and i need to save some money.

- It would actually cost you more to reload steel.

- Q: What are the different types of steel coil finishes?

- There are several different types of steel coil finishes, including mill finish, galvanized finish, painted finish, and stainless steel finish.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- we may use the formula ΔL=α(Lo)(Tf-To) where Lf is the length of steel at temp. Tf Lo is length at To α is the coefficient of linear expansion of steel which is 11x10^-6/°C ΔL=0.78mm (the change in length) Lo=? ΔL=α(Lo)(Tf-To) Lo=ΔL/[α(Tf-To)] Lo=(0.78x10^-3m)/[(11x10^-6/°C)(35°C-2...? Lo=5.455m answer

- Q: Can steel coils be used in electrical applications?

- Certainly, electrical applications can make use of steel coils. In the realm of electrical circuits, steel coils often serve as magnetic cores in transformers and inductors, which are indispensable components. The steel employed in these coils typically consists of high-quality electrical steel, possessing distinct magnetic attributes, including low core losses and high permeability. These attributes empower the steel coils to efficiently transmit electrical energy between various circuit components. Furthermore, steel coils can also find utility in other electrical applications, such as the construction of electric motors and generators. Taking everything into account, steel coils are extensively employed in electrical applications due to their magnetic properties and their capacity to handle high currents and temperatures.

- Q: Specifically, for the main support beam found in a basement.

- Glulam. Cheaper to buy, cheaper to install. Takes up less space than an I-beam.

Send your message to us

BMP Z25 PPGI Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords