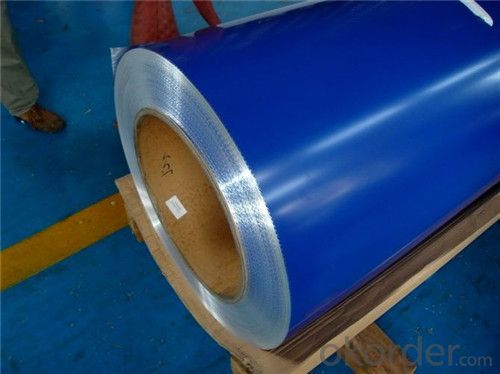

BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

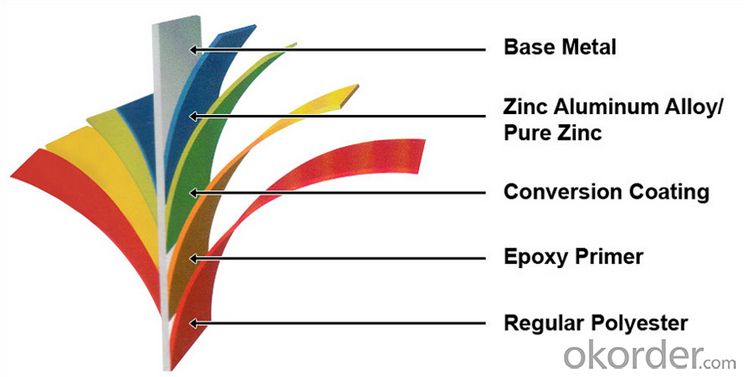

Structure of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Description of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Galvanized sheet or coil is defined as a carbon steel sheet coated with zinc on both sides. Continuous hot dipping, or electro-galvanizing are the two processes used to produce galvanized sheet and coil. Generally speaking, the hot dip process consists of passing the steel through a bath of molten zinc. The electro galvanizing process consists of the application of zinc by electrolytic disposition.The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer.

Main Feature of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

1. Resistance to Corrosion Has better performance in corrosion resistance than hot dip galvanized coil/sheet of the same thickness and its service life is 1-5 times longer than general hot dip galvanized coil/sheet.

2. Machinability Can satisfy the processing requirements of rolling, coiling and others processes alike.

3. Thermal Resistance Can sustain the environment at 315Centigrade for long time.

4. High Reflectivity Reflection ability of heat and light is twice as much as those of hot dip galvanized steel coil/sheet, and its reflectivity is more than 0.75, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction material of saving energy.

Applications of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing cars, ships,containers household electric appliances, other industries usage. |

FAQ of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2.What's your MOQ?

25MT, it is for one container.

3.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

5.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: if steel is heated from room temperature (20c) to (500c) what would be the change in density?coefficient for linear expansion of steel 12x10^-6 k density of steel 7800 kg

- First you have to convert the coefficient of linear expansion to a coefficient of volumetric expansion. Multiply the coefficient of linear expansion by 3: Coefficient of expansion of steel,β:12E-6/°K x 3 = 36E-6/°K Difference in temperature: 480°K ΔV = VoβΔT ΔV = Vo x (0.000036) x 480 ΔV = 1m? x 0.017 ΔV = 0.017m? Originally, the steel was at 7800 kg/m? Now, the steel was at 7800 kg/ 1.017m?, or 7670 kg/m? Change in density = 7670 - 7800 = -130kg/m?

- Q: How are steel coils used in the production of steel handles?

- Steel coils are used in the production of steel handles by being processed and shaped into the desired form for the handle. The coils are first uncoiled and then cut into specific lengths. These lengths are then shaped, bent, and welded to create the handle's structure. The steel coils provide the raw material necessary for the production of sturdy and durable steel handles.

- Q: What are the different methods of cutting steel coils into sheets?

- There are several methods used to cut steel coils into sheets, including shearing, slitting, and laser cutting. Shearing involves using a straight blade to cut through the coil, while slitting uses circular blades to make multiple cuts simultaneously. Laser cutting, on the other hand, utilizes a high-powered laser beam to melt through the steel. Each method has its own advantages and is chosen based on factors such as the desired precision, speed, and cost-effectiveness.

- Q: How are steel coils used in the production of wire products?

- Steel coils are an essential component in the production of wire products. These coils are typically made from high-quality steel and are used as a raw material for wire drawing processes. Wire drawing is a manufacturing technique used to reduce the diameter of the steel coil and transform it into various wire products. To begin the process, a steel coil is placed on a wire drawing machine. The machine then pulls the coil through a series of dies, which are progressively smaller in size. As the coil passes through each die, the diameter of the wire is reduced, resulting in a thinner and longer strand of wire. This process can be repeated several times until the desired wire thickness is achieved. Once the wire is drawn, it can be further processed to create various wire products such as fencing, nails, screws, springs, and electrical wires. The wire can be cut to specific lengths, bent, or shaped according to the intended use. Additionally, it can undergo treatments such as galvanizing or coating to enhance its durability and resistance to corrosion. Steel coils provide several advantages in the production of wire products. Firstly, they offer a consistent and uniform material, ensuring that the resulting wire products have consistent quality and performance. Secondly, steel coils are easily transportable and can be stored efficiently, making them a cost-effective option for manufacturers. Lastly, the versatility of steel allows for the production of wire products with different tensile strengths and properties to meet specific industry requirements. In conclusion, steel coils play a crucial role in the production of wire products. They are the primary raw material used in wire drawing processes, where they are transformed into various wire products through a series of reduction steps. The resulting wire products find applications in a wide range of industries, making steel coils an indispensable component in the manufacturing sector.

- Q: How do steel coils contribute to the manufacturing of electrical equipment?

- Steel coils play a crucial role in the manufacturing of electrical equipment due to their unique properties and versatility. Firstly, steel coils are used in the production of transformer cores, which are essential components in electrical equipment. The magnetic properties of steel make it an ideal material for transformer cores as it allows for efficient energy transfer and reduces energy losses. The coil shape of the steel enables it to generate a magnetic field that facilitates the transformation of voltage levels, thus ensuring the proper functioning of electrical equipment. Moreover, steel coils are commonly used in the production of motors and generators. These devices rely on magnetic fields to convert electrical energy into mechanical energy and vice versa. The coil shape of the steel allows for the creation of electromagnetic fields, which are necessary for the operation of motors and generators. Additionally, the strength and durability of steel ensure that the coils can withstand the high temperatures and mechanical stresses that are often encountered in electrical equipment. Furthermore, steel coils are utilized in the construction of electrical conductors, such as wires and cables. These conductors enable the transmission of electricity from power sources to various electrical devices. Steel, with its high electrical conductivity, ensures efficient power transmission while also providing mechanical strength and protection from external factors such as corrosion and wear. The coil shape of steel wires further enhances their flexibility, making them suitable for various applications in electrical equipment manufacturing. Overall, steel coils contribute significantly to the manufacturing of electrical equipment by providing the necessary magnetic properties for transformer cores, enabling the generation of electromagnetic fields in motors and generators, and facilitating efficient power transmission in electrical conductors. Their versatility, strength, and durability make steel coils an indispensable component in the production of reliable and high-performance electrical equipment.

- Q: How are steel coils used in the manufacturing of seat belts?

- Steel coils are used in the manufacturing of seat belts to provide strength and durability. The steel coils are typically used as the main structural component in the seat belt, ensuring that it can withstand high levels of force during an impact. Additionally, the coils help to maintain the proper tension in the seat belt, ensuring that it functions effectively in restraining the occupants in the event of a collision.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Factors such as mishandling, improper stacking, exposure to moisture or extreme temperatures, and inadequate packaging can lead to dents, scratches, corrosion, and even deformation of the coils. Adequate precautions and secure packaging are necessary to minimize the risk of damage during storage or transportation.

- Q: What is the process of uncoiling a steel coil?

- The process of uncoiling a steel coil involves placing the coil on a mandrel or a reel, then using a motorized or manual unwinding mechanism to slowly unwind the coil. The coil is typically fed through a straightening device to remove any bends or twists before it is further processed or cut into desired lengths.

- Q: What is the role of steel coils in the electrical industry?

- The role of steel coils in the electrical industry is significant as they serve multiple purposes in various applications. Steel coils are used as components in transformers, which are essential for power distribution and voltage regulation. These coils are responsible for transferring electrical energy from one circuit to another, allowing for efficient transmission of electricity across long distances. Additionally, steel coils are utilized in the production of electric motors and generators. They are wound around the stator and rotor to create magnetic fields, which enable the conversion of electrical energy into mechanical energy and vice versa. This process is crucial in various industries, including automotive, manufacturing, and renewable energy sectors. Steel coils also play a role in the production of electrical cables and wiring. They are used to provide strength, durability, and protection to the conductive copper or aluminum wires within the cables. These coils are responsible for maintaining the structural integrity of the cables, ensuring safe and efficient transmission of electricity. Furthermore, steel coils find application in electrical equipment such as solenoids and relays, where they help create magnetic fields to control the flow of electrical current. They are also used in various electrical appliances, including refrigerators, air conditioners, and televisions, where they act as essential components in the functioning of these devices. In summary, steel coils have a vital role in the electrical industry. They are used in transformers, motors, generators, cables, and various electrical equipment, contributing to the efficient distribution, conversion, and transmission of electrical energy.

Send your message to us

BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords