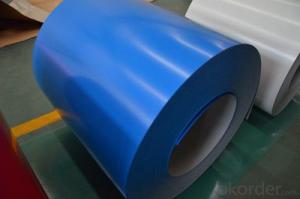

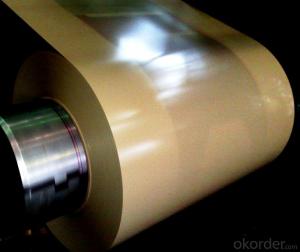

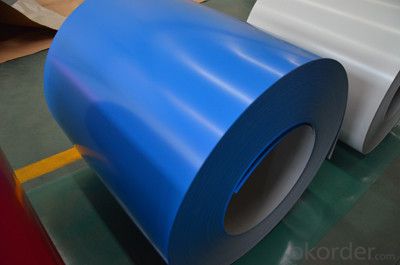

BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

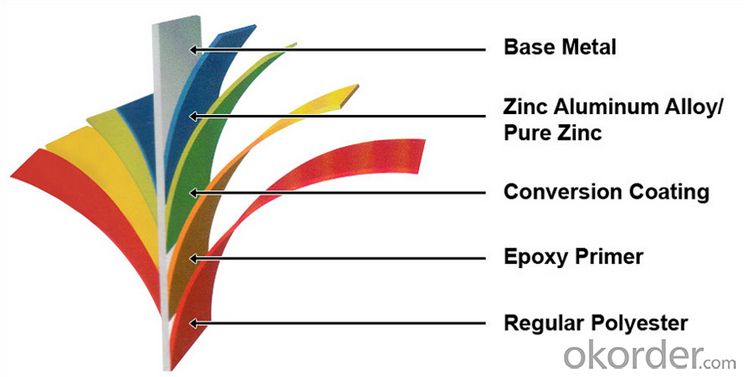

Structure of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

Description of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

Cold rolled steel coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold rolled steel coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The cold rolled steel coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the cold rolled steel coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final cold rolled steel coil may be manufactured in the form of sheets, strips, bars, or other forms.

Main Feature of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

Applications of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

1. Base metal for coated and dipped products.

2. Home appliance

3. Precise welding tube

4. Flux cored welding wire

5. Bicycle, battery shell,

6. Automobile fitting, hardware

7. Enameling industry etc.

Specifications of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils can vary depending on the grade and composition of the steel, but it is generally high, ranging from 400 to 700 megapascals (MPa).

- Q: Molton is formed at 2800 F. Thats a fact. Now jet fuel at its hottest is 1800. Where does the other 1000 degress come in? And it was found at the WTC 7 site. Was this hit by a plane? A simple fire COULD NOT produce molton. This is a fact. Molton is formed during controlled demoliton of a building since all the bombs in the buiding go off and its very very hot. The fact there was MOLTON at the site is shocking to some since it is IMPOSSIBLE for molton to form from jet feul alone. Impossible. It needed another source. Now the claim that I'll get is that it weakened the stell but then we would find weak steel not molton. Why do you seem to throw this off of your shoulder? Do you not want to belive it? I'm no jet fuel guy but I know you cannot make molton by using just jet fuel. This is really proof that 9/11 was an inside job.

- People who believed the buildings collapsed because of the planes are far far off. 1. Burning jet fuel CANNOT melt steel - FACT! 2. The twin towers were built to withstand a hit from a Boeing 707 - FACT 3. NORAD didn't respond - for the first time EVER! - FACT! 4. The pentagon has the most CCTV cameras than any other buildings in the world and they only release the tape which the plane is not visible, they also confiscated the tape from the store opposite which would have shown the plane - if it existed. State sponsored terrorism has been around for along tI'me, im surprised at how many people still believe the official story.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are commonly used in the production of oil and gas machinery for various purposes. They are utilized in the manufacturing of pipes, tanks, and pressure vessels, providing structural strength and durability to withstand the harsh conditions of oil and gas operations. Additionally, steel coils are shaped and formed into components such as valves, fittings, and flanges, which are crucial for the proper functioning of the machinery. Overall, steel coils play a vital role in ensuring the reliability and efficiency of oil and gas machinery.

- Q: What is the type of stainless steel used in knifes.

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q: What other metal is used to make rings? My girlfriend is allergic to stainless steel, but she wears a silver/grayish color ring, but I'm not sure what metal it is. Any ideas? Thanks!

- can she wear sterling silver or white cooper?

- Q: I'v had 5 people at school say steel is stonger than Titanium and some(5) kids at school say titanium stronger then steel but i looked it up on the internet and i got soem web sites that say steel is stronger then titanium and some sites that say titanium is stonger then steel sooooo???? witch one is strongerPS i no tungsten is stronger then steel.... and titanium.................

- Titanium has better high temperature strength than steel. Titanium doesn't resist shocks like steel can. It's more brittle. It's also far more difficult to weld. Titanium must be welded in an oxygenless environment. The average strength of steels that are made is under that of titanium. However, the strongest steel is stronger than the strongest titanium. Steel is the only viable building material. Titanium is too rare, expensive, and hard to handle for structures of great height. Hope this helps. Peace and Love.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are used in the manufacturing industry for a variety of purposes such as making automotive parts, appliances, construction materials, and machinery. The coils are typically unwound and processed into sheets or strips, which can then be shaped, cut, or formed into the desired finished product. The versatility, strength, and durability of steel make it a valuable material in the manufacturing process, and the use of coils helps maximize efficiency and productivity.

- Q: I wasn't expecting much because i knew it was cheap (Trying to avoid high prices) But anyway i cut a few bottles and cans and i noticed the very edge of the blade was starting to bend. I ignored it and tried it on a 3 inch limb, and the whole blade bent sideways where the limb hit it.I heard cold steel was supposed to be top quality and I wanted to know how durable their swords are and if they're worth it. Thanks!

- O.Adequate. First and fundamental it takes coaching and observe to use a katana. There may be a little bit component known as 'system'. You need to to search out an trainer. Except you're a fairly significant man, an O Katana is conveniently too large for you. Weapons of this way were not used for dueling, they have been further anti-cavalry weapons. As a substitute cumbersome for one in the direction of one combat. The cold steel katanas are not very regularly correct varieties of a japanese sword - missing finesse and poorly balanced. They are going to take a beating though and it seems like that's what you probably giving it. Severely, you possibly more often than not a hazard to your self and possible others round you - to search out an teacher.

- Q: What are the factors that affect the quality of steel coils?

- The quality of steel coils can be influenced by various factors. To begin with, the composition of the steel itself plays a vital role in determining its quality. Impurities like sulfur or phosphorus can have a negative impact on the strength, durability, and overall performance of the steel. Additionally, the quality of the steel is affected by its carbon content, alloying elements, and heat treatment. Furthermore, the quality of the steel coils is greatly affected by the manufacturing process and techniques utilized during production. Factors such as the cleanliness of the production environment, the precision of the rolling and cooling processes, and the control of temperature and pressure throughout manufacturing all contribute to the final quality of the coils. Additionally, the surface quality of the steel coils is a crucial factor. Any defects or imperfections on the surface, such as scratches, dents, or corrosion, can compromise the integrity and functionality of the coils. It is essential to handle, store, and transport the coils properly to maintain their surface quality. Moreover, the mechanical properties of the steel coils, including tensile strength, yield strength, and elongation, are essential indicators of their quality. These properties depend on various factors, such as the type of steel, its thickness, and the processing conditions. Lastly, external factors such as environmental conditions, like humidity and temperature, can affect the quality of steel coils. Exposure to moisture or extreme temperatures can lead to corrosion or other forms of degradation, impacting the overall quality and lifespan of the coils. In conclusion, the quality of steel coils is influenced by several factors, encompassing the composition of the steel, the manufacturing process, surface quality, mechanical properties, and external environmental conditions. It is crucial to carefully control and monitor these factors to produce high-quality steel coils that meet the desired specifications and standards.

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- Steel is mostly iron. However, it is an alloy or solid solution, or mixture of iron and other metals or sometimes carbon. All steel is a mixture. there are many varieties.

Send your message to us

BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords