prepainted Rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

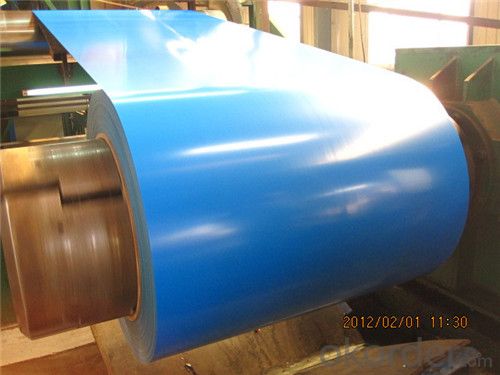

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of coil edge trimming machines?

- There are several types of coil edge trimming machines available in the market. Some common types include manual coil edge trimmers, pneumatic coil edge trimmers, and automatic coil edge trimmers. Manual coil edge trimmers require manual operation and are suitable for low volume production. Pneumatic coil edge trimmers use compressed air to power the trimming process, making them faster and more efficient. Automatic coil edge trimmers are fully automated machines that can handle high volume production, enhancing productivity and reducing labor requirements.

- Q: what exactly does it mean when some sword makers refer to finding the truth of steel. I have heard that many have tried to find the truth but i dont really understand what there is to find.

- I am unsure of what the Truth of Steel is, but here is the Riddle of Steel (from Conan) Thulsa Doom: Yes! You know what it is, don't you boy? Shall I tell you? It's the least I can do. Steel isn't strong, boy, flesh is stronger! Look around you. There, on the rocks; a beautiful girl. Come to me, my child... Thulsa Doom: [coaxes the girl to jump to her death] Thulsa Doom: That is strength, boy! That is power! What is steel compared to the hand that wields it? Look at the strength in your body, the desire in your heart, I gave you this! Such a waste. Contemplate this on the tree of woe. Crucify him!

- Q: What are the dimensions of steel coils used in the automotive industry?

- Steel coils used in the automotive industry come in various dimensions, which are determined by the specific application and requirements. Normally, the thickness of these coils falls between 0.5mm and 3mm, while the width ranges from 500mm to 2000mm. The length of the coils is subject to variation, depending on the production process and customer specifications. Furthermore, the weight of the coils can range from a few hundred kilograms to several tons. It is worth mentioning that these dimensions serve as general guidelines and may differ based on the particular needs of the automotive manufacturer.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- steel wool = iron fibers and rusts easily in air iron + Oxygen BUT the blue soap protects the iron at first. that needs to be cleaned off. damp surfaces speed the rusting but compeletly underwater there is not much O2, ther eis some temperature has an effect. the rusting depends ofn the area of the fibers which does NOT change when you cut th epad in smaller pieces. a good beginners experiment In old times thye thought the rusted material would lose weight becasuse it was not solid iron any more careful experiments showed it gained weight and lead to and understanding of chemistry

- Q: What is the typical size and weight of a steel coil?

- The typical size and weight of a steel coil can vary depending on the specific application and industry. However, in general, steel coils are typically manufactured in widths ranging from 0.5 to 2 meters (1.6 to 6.6 feet) and can weigh anywhere between 1 to 25 metric tons (2,205 to 55,116 pounds). The exact size and weight of a steel coil will depend on factors such as the type of steel used, the intended use of the coil, and the manufacturing process employed.

- Q: Which one is stronger steel or metal ( for bow and arrows) please answer I need it for a book I'm writing

- hi Asking this question in engineering category would give you the following answer steel is a subcategory of metals moreover steel is iron with some other additions( mainly carbon) strong in the engineering sense is not a specific word..i mean we , in engineering, have many scales to categorize metals ( which include steel)..like hardness,corrosion,elasticity, and even heat conductivity...every metal could be strong in some and weak in other but i can understand that you are not an engineering type :) that's why here's a special answer for you steel usually has the silver shiny color ( i am not sure all grades of steel have this color)...it would be more EPIC to use steel bow and arrows... if it's a fictitious books...you can just use Iron or any name you can made up... You can search....how did the ancients make their bows and arrows? thanks :)

- Q: How are steel coils used in the production of packaging materials?

- Steel coils are used in the production of packaging materials by being processed into thin sheets or strips that can be shaped and formed into containers, cans, or other packaging components. These steel sheets are often used as a base material for packaging products due to their strength, durability, and ability to protect goods during transportation and storage.

- Q: How do steel coils impact the overall cost of production?

- Steel coils can have a significant impact on the overall cost of production. The cost of steel coils is a major component in the production process, as they are used as raw materials in various industries such as automotive, construction, and manufacturing. Fluctuations in the price of steel coils can directly affect the cost of production, ultimately influencing the final price of the end product. Additionally, factors such as transportation and storage costs also contribute to the overall impact of steel coils on production costs.

- Q: What are common uses for steel coils?

- Steel coils are commonly used in various industries such as automotive, construction, and manufacturing for applications like sheet metal fabrication, structural components, pipes, and electrical appliances.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils find extensive use in various industries due to their robustness and durability. Nevertheless, selecting the appropriate material necessitates considering some essential distinctions between the two. One of the primary disparities lies in the composition of the materials. Steel coils, primarily comprising iron and carbon, incorporate additional elements to enhance specific properties. Conversely, stainless steel coils contain iron, carbon, and a substantial amount of chromium, which imparts them with distinctive corrosion-resistant attributes. Owing to the presence of chromium, stainless steel coils outperform regular steel coils in their resistance to corrosion, tarnishing, and rust. This renders stainless steel coils highly suitable for applications within environments characterized by elevated humidity, moisture, or exposure to corrosive substances. On the contrary, steel coils are more susceptible to rust and may necessitate supplementary protective coatings or treatments to avert corrosion. Another notable differentiation concerns the visual appearance of the two materials. Stainless steel coils boast a lustrous and reflective surface, endowing them with an aesthetically pleasing allure. They commonly find application in contexts where appearance holds significance, such as kitchen appliances, architectural structures, or decorative purposes. Conversely, steel coils exhibit a matte or dull finish and are frequently employed in industrial applications where visual aesthetics are of secondary concern. In terms of strength, both steel and stainless steel coils exhibit excellent mechanical properties. However, stainless steel coils generally demonstrate greater tensile strength and enhanced resistance to high temperatures. Consequently, they prove well-suited for applications necessitating strength, such as the construction, automotive, or aerospace industries. Lastly, cost represents a factor warranting consideration while comparing steel coils to stainless steel coils. Steel coils generally offer a more cost-effective option due to the lower expense of raw materials and simpler manufacturing processes. Nevertheless, when factoring in the added value of corrosion resistance and longevity, stainless steel coils may emerge as a more economical choice in the long run, requiring less maintenance and replacement. To conclude, steel coils and stainless steel coils possess distinct properties and characteristics, rendering them suitable for specific applications. Stainless steel coils exhibit superior corrosion resistance, a glossy appearance, and heightened tensile strength, while steel coils prove more cost-effective. Ultimately, the selection between the two hinges on the precise requirements of the application, encompassing factors such as the environment, aesthetics, strength, and budget.

Send your message to us

prepainted Rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords