Premium Green Colored Corrugated Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Premium Green Colored Corrugated Roofing Metal Sheet

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

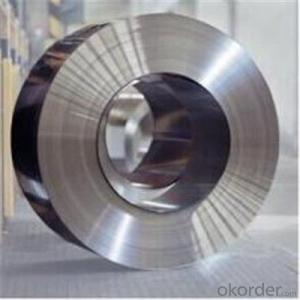

- Q: What is the thickness tolerance of steel strips?

- The thickness tolerance of steel strips may differ based on the particular grade and manufacturing process employed. Generally, the steel strip thickness tolerance adheres to an industry standard of approximately +/- 10% of the designated thickness. However, it is essential to acknowledge that distinct uses may demand stricter tolerance criteria. For example, sectors like automotive or aerospace may necessitate narrower thickness tolerances to guarantee accurate fitting and optimal performance. Consequently, it is imperative to refer to the pertinent industry standards or specifications to ascertain the precise thickness tolerance prerequisites for a given steel strip application.

- Q: How are steel strips processed for surface shearing?

- Steel strips are processed for surface shearing by passing them through a shearing machine that cuts off the top layer of the strip, resulting in a smooth and clean surface finish.

- Q: What are the different heat treatment methods for steel strips?

- The different heat treatment methods for steel strips include annealing, quenching and tempering, normalizing, and hardening.

- Q: What industries use steel strips?

- Several industries use steel strips, including automotive, construction, manufacturing, and packaging. Steel strips are commonly used in the production of automobile components, such as body panels and chassis parts. In the construction industry, they are utilized for building structures, roofing, and reinforcement. Manufacturing industries use steel strips for various applications, such as forming machine parts, pipes, and electrical appliances. Additionally, steel strips are employed in the packaging industry for making cans, containers, and closures.

- Q: Can steel strips be used in marine applications?

- Yes, steel strips can be used in marine applications. Steel is a durable and corrosion-resistant material, making it suitable for various marine environments. It can be used in applications such as shipbuilding, offshore structures, and marine equipment due to its strength and ability to withstand harsh conditions at sea.

- Q: What are the different cleaning methods for steel strips?

- There are several different cleaning methods for steel strips, including mechanical cleaning, chemical cleaning, and electrochemical cleaning. Mechanical cleaning involves using abrasive materials or brushes to physically remove dirt, debris, or scale from the surface of the steel strip. Chemical cleaning involves using various cleaning solutions or solvents to dissolve or loosen contaminants on the strip. Electrochemical cleaning utilizes an electric current to remove oxidation or other surface contaminants through the process of electrolysis. The choice of cleaning method depends on the specific requirements and condition of the steel strip.

- Q: How are steel strips processed for interlocking?

- To achieve interlocking, steel strips undergo a series of steps involving precision cutting, shaping, and assembly. It all begins with selecting high-quality steel strips that meet the necessary specifications. These chosen strips are then cut into specific lengths and widths using advanced cutting techniques like shearing or laser cutting. After the initial cutting, further processing may be done to create interlocking features. This can involve shaping the edges of the strips to form interlocking profiles or adding specialized notches or grooves that allow for secure connections. Machining techniques like milling or grinding might be employed to achieve the desired interlocking design. Once the interlocking features are formed, the steel strips undergo careful inspection to ensure accuracy and quality. Any imperfections or burrs are removed through deburring or polishing processes to guarantee smooth and precise interlocking. The final step in processing steel strips for interlocking is assembly. The interlocking profiles of the strips are meticulously aligned and joined together using welding, riveting, or other suitable methods. This assembly process ensures that the interlocking steel strips create a strong and secure connection capable of meeting the requirements of the intended application. In summary, the process of processing steel strips for interlocking involves a combination of cutting, shaping, and assembly techniques to create precise interlocking profiles. This guarantees that the resulting interlocking system offers a reliable and durable solution for various applications such as construction, manufacturing, or infrastructure projects.

- Q: What are the factors that affect the dimensional stability of steel strips?

- Steel strips can experience changes in size and shape due to various factors. Temperature plays a significant role, as high temperatures cause expansion and low temperatures cause contraction. Therefore, it is important to choose a steel grade that has appropriate thermal expansion properties for the intended temperature range. Moisture also affects the dimensional stability of steel strips. High humidity or moisture can lead to corrosion, resulting in swelling or warping of the steel strip. To prevent this, proper storage and handling practices should be followed to keep moisture out. Mechanical stress is another factor that can impact the dimensional stability of steel strips. Excessive bending or stretching can introduce residual stresses, which can cause dimensional changes over time. Care must be taken during processing, handling, and installation to minimize the introduction of excessive mechanical stress. The chemical composition of the steel strip is also important. Elements like carbon, silicon, and manganese can affect the thermal expansion properties of the steel. Impurities or uneven distribution of alloying elements can cause uneven expansion or contraction, leading to dimensional changes. The manufacturing process used to produce the steel strip can also affect its dimensional stability. Factors such as rolling temperature, cooling rate, and annealing processes can impact the microstructure and resulting dimensional stability. Proper control and optimization of the manufacturing process can help reduce dimensional variations. Furthermore, applying coatings or surface treatments to the steel strip can influence its dimensional stability. Some coatings or treatments may introduce stress or alter the thermal expansion properties, impacting the dimensional stability. It is important to select appropriate coatings or treatments that are compatible with the intended application and minimize dimensional changes. In conclusion, the dimensional stability of steel strips is influenced by temperature, moisture, mechanical stress, chemical composition, manufacturing process, and coating or surface treatment. It is crucial to carefully consider and manage these factors to ensure the desired dimensional stability in different applications.

- Q: What are the environmental considerations for steel strips?

- Some environmental considerations for steel strips include the energy consumption and emissions associated with the production process, the depletion of natural resources used in steel production, the potential for pollution and waste generation, and the end-of-life disposal or recycling options for steel strips. Additionally, the transportation and logistics involved in the supply chain of steel strips can contribute to carbon emissions and environmental impacts.

- Q: How do steel strips compare to steel sheets?

- Various industries utilize steel strips and steel sheets, which are both common forms of steel. However, they vary in terms of thickness, width, and application. Steel strips, being narrow and elongated, typically boast a thickness ranging from 0.2mm to 6mm and a width below 600mm. These strips find frequent use in precise applications, such as automotive components, electrical appliances, and construction materials. Their slender nature allows easy manipulation, enabling bending, forming, and cutting into specific shapes. Additionally, their narrow size makes them an ideal choice for weight reduction in crucial applications. Conversely, steel sheets are larger and flat pieces of steel, usually featuring a thickness between 0.6mm and 25mm and a width exceeding 600mm. Construction, shipbuilding, industrial machinery, and general fabrication widely employ steel sheets. Their structural strength and stability render them suitable for load-bearing purposes, including building frameworks, bridges, and heavy machinery. Although both steel strips and steel sheets share the same material, their differing dimensions and applications provide them with distinct utilities. Steel strips exhibit versatility, allowing intricate designs and precise manufacturing. On the other hand, steel sheets offer strength and stability for heavy-duty applications. Ultimately, the choice between steel strips and steel sheets depends on the specific project requirements and desired characteristics of the final product.

Send your message to us

Premium Green Colored Corrugated Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords