Cold Rolled Galvanized Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 m.t.

- Supply Capability:

- 22232332 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Standard | Galvanized Steel Coil Grade | Zinc Coating | Width | Thickness | Length | Capacity/Year |

| JIS G3302 | SGCH/SGCC-SGC570/SGHC-SGH340 | Z40-275g | 30-914mm | 0.3-4.0mm | Coil | 1,00,000Ton |

| EN 10346 | DX51D+Z/DX53D+Z/S220GD-S550GD | Z40-275g | 30-914mm | 0.3-4.0mm | Coil | 1,00,000Ton |

| ASTM A653 | CS-B/SS255-550 | Z40-275g | 30-914mm | 0.3-4.0mm | Coil | 1,00,000Ton |

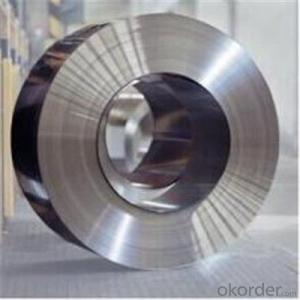

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: What are the categories of strip steel? How do you distinguish it?

- Steel is iron, carbon as the main component of the alloy, its carbon content is generally less than 2.11%. Steel is one of the most important metal materials in economic construction.

- Q: What are the different cleaning methods for steel strips?

- There exist various cleaning techniques available for steel strips, which can be selected based on the specific requirements and needs of the application. Some commonly employed cleaning methods for steel strips include: 1. Mechanical cleaning: This method entails the utilization of mechanical tools like wire brushes, sandpaper, or abrasive pads to physically eliminate dirt, rust, or other contaminants from the surface of the steel strips. Mechanical cleaning is effective in eliminating heavy deposits or stubborn stains. 2. Chemical cleaning: Chemical cleaning involves the use of cleaning agents or solvents to dissolve or eradicate contaminants from the steel strips. The choice of cleaning agents depends on the specific contaminants that need to be eliminated. Acid-based cleaners are frequently used to remove rust, while alkaline cleaners are effective in eliminating grease or oil. 3. Electrolytic cleaning: This method requires immersing the steel strips in an electrolyte solution and applying an electric current to eradicate contaminants. Electrolytic cleaning is particularly effective in removing rust or scale from the steel strip's surface. Additionally, it can be utilized to passivate the steel surface, enhancing its resistance to corrosion. 4. Ultrasonic cleaning: Ultrasonic cleaning employs high-frequency sound waves to generate tiny bubbles in a cleaning solution. These bubbles collapse near the surface of the steel strips, creating a scrubbing action that aids in removing contaminants. Ultrasonic cleaning is efficient in eliminating fine particles or particles that are challenging to reach using other cleaning methods. 5. Steam cleaning: Steam cleaning involves the utilization of high-pressure steam to eliminate contaminants from the surface of the steel strips. The heat and pressure of the steam facilitate the breakdown of dirt, grease, or oil, making it easier to remove them. Steam cleaning is a rapid and efficient method for cleaning steel strips, particularly in industrial or manufacturing settings. It is crucial to select the appropriate cleaning method based on the type and severity of contamination, as well as the desired level of cleanliness. By implementing proper cleaning and maintenance practices for steel strips, their lifespan can be extended, ensuring optimal performance in various applications.

- Q: How are steel strips used in the manufacturing of hydraulic systems?

- The manufacturing of hydraulic systems utilizes steel strips in various ways. To begin with, hydraulic cylinders, which are essential components of hydraulic systems, commonly employ steel strips in their fabrication. These cylinders convert fluid power into mechanical force to execute tasks like lifting heavy objects or operating machinery. The steel strips are manipulated through cutting, bending, and welding to form the cylindrical shape of the hydraulic cylinder. This construction provides the necessary strength and rigidity to withstand high pressures and forces. In addition, hydraulic tubing, which serves as a conduit for hydraulic fluid, benefits from the use of steel strips in its production. Steel strips are rolled and shaped into tubes of diverse diameters and thicknesses to ensure that the tubing can endure the pressures and vibrations encountered within hydraulic systems. The steel construction also offers excellent resistance to corrosion and high temperatures, thereby preserving the integrity and longevity of the hydraulic system. Moreover, hydraulic valves and fittings are manufactured using steel strips. Valves control the flow and direction of hydraulic fluid, while fittings connect various components together. Steel strips are machined and shaped to create the valve bodies and fittings, ensuring their ability to withstand the high pressures, forces, and temperature fluctuations experienced in hydraulic systems. The strength and durability of steel make it an ideal material for these critical components, as they require a tight seal and the ability to withstand continuous use. In summary, steel strips are crucial in the manufacturing of hydraulic systems due to their strength, durability, and resistance to corrosion. Whether utilized in hydraulic cylinders, tubing, valves, or fittings, steel strips guarantee the effective and reliable operation of hydraulic systems. This enables the efficient transfer of fluid power to perform a variety of tasks in industries such as construction, agriculture, and manufacturing.

- Q: How are steel strips used in the manufacturing of tools?

- Steel strips are commonly used in the manufacturing of tools as they provide a strong and durable material for cutting, shaping, and forming various components. These strips are often used as the base material for creating blades, cutting edges, and other sharp elements required in tool production. Additionally, steel strips can be heat treated to enhance their hardness and strength, making them ideal for withstanding the rigors of tool usage.

- Q: What are the different surface textures available for steel strips?

- There are several different surface textures available for steel strips, including smooth, brushed, polished, embossed, and textured.

- Q: What is the thermal conductivity of a steel strip?

- The thermal conductivity of a steel strip refers to its ability to conduct heat. Steel is known to have relatively high thermal conductivity compared to other materials, which means it can transfer heat more efficiently. The specific thermal conductivity of a steel strip can vary depending on factors such as the type of steel, its composition, and temperature. However, on average, the thermal conductivity of steel ranges from around 15 to 50 W/(m·K), with some variations for different types of steel. This property makes steel strips suitable for applications where efficient heat transfer is required, such as in heat exchangers, industrial machinery, and construction materials.

- Q: How do steel strips contribute to weldability in various applications?

- Steel strips can contribute to weldability in various applications by providing a clean and consistent base material for welding. They ensure uniformity in thickness and composition, which helps in achieving strong and reliable weld joints. Additionally, steel strips with specific alloying elements can enhance the weldability by improving the ability to withstand heat and reducing the risk of cracking or distortion during welding. Overall, steel strips play a crucial role in facilitating the welding process and ensuring the quality and performance of welded components in different applications.

- Q: What are the challenges faced in the production of steel strips?

- There are several challenges faced in the production of steel strips. One of the major challenges is the high energy consumption during the manufacturing process. Steel production requires a considerable amount of energy, both in terms of electricity and fuel. This poses a challenge not only in terms of cost but also in terms of environmental sustainability. Another challenge is the quality control of the steel strips. Ensuring consistent and uniform thickness, width, and surface quality is crucial in producing high-quality steel strips. Any variation in these parameters can lead to defects and inconsistencies in the final product. Maintaining the desired mechanical properties of the steel strips is also a challenge. The production process involves various heat treatments and mechanical processing, which must be carefully controlled to achieve the desired strength, hardness, and ductility of the steel. Any deviation from the required properties can render the steel strips unsuitable for their intended applications. Furthermore, the production of steel strips often involves handling and processing of large and heavy coils. This can be a logistical challenge, requiring specialized equipment and infrastructure for efficient transportation, storage, and handling. Lastly, the steel industry faces the challenge of increasing competition and market demand. To stay competitive, steel manufacturers need to continuously improve their production processes, reduce costs, and meet the changing demands of customers. This requires investment in research and development, as well as adaptation to new technologies and market trends. Overall, the production of steel strips is a complex process that requires overcoming challenges related to energy consumption, quality control, mechanical properties, logistics, and market demands. However, with continuous innovation and improvement, these challenges can be addressed, leading to the production of high-quality steel strips that meet the requirements of various industries.

- Q: How are steel strips used in the production of oil and gas pipelines?

- Steel strips are used in the production of oil and gas pipelines as they serve as the main material for manufacturing the pipes. These strips are typically formed and welded into cylindrical shapes to create the pipelines that transport oil and gas over long distances. The steel's strength, durability, and resistance to corrosion make it an ideal choice for ensuring the safety and efficiency of oil and gas transportation.

- Q: How are steel strips processed for roll forming?

- Steel strips are processed for roll forming through a series of steps to achieve the desired shape and dimensions. The process typically begins with the uncoiling of a large coil of steel strip, which is then fed into a roll forming machine. The steel strip passes through a series of rollers, which gradually shape it into the desired profile. These rollers are carefully designed to create specific bends, curves, and angles in the strip. The number and arrangement of the rollers can vary depending on the complexity of the desired shape. As the steel strip passes through the rollers, it is carefully guided and supported to ensure accurate and consistent shaping. Guide rolls, side rolls, and idler rolls are used to maintain the strip's position and prevent any wrinkling or twisting during the process. To further enhance the shaping process, some roll forming machines may incorporate additional techniques such as pre-notching or pre-punching. These techniques involve creating small cuts or holes in the strip before it enters the rollers, allowing for easier bending and forming. Once the steel strip has been fully shaped, it is then cut to the desired length. This can be done either during the roll forming process itself or as a separate step after the strip has been formed. Various cutting methods can be used, including shearing, sawing, or punching, depending on the specific requirements of the final product. After cutting, the formed steel strips may undergo additional processes such as punching holes, embossing, or adding surface finishes. These processes help to add functionality or aesthetic appeal to the final product. Overall, the roll forming process for steel strips involves precise shaping, careful support, and accurate cutting to create a wide range of profiles and shapes. This versatile manufacturing technique is widely used in industries such as construction, automotive, and appliances to produce components and structures with high strength and durability.

Send your message to us

Cold Rolled Galvanized Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 m.t.

- Supply Capability:

- 22232332 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords