Hot Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22223333 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

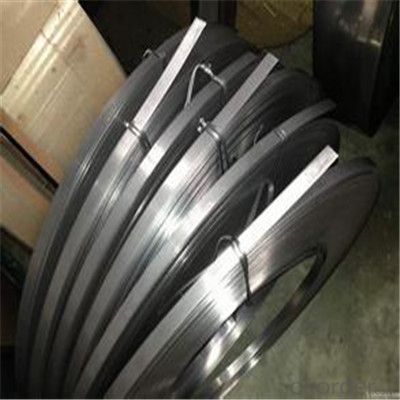

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips cold rolled?

- Cold rolling is a process wherein steel strips are passed through a series of rollers at room temperature to decrease their thickness and enhance their surface finish. The initial stage involves cleaning the steel strip to eliminate any impurities or surface contaminants. Once cleaned, the strip is fed into rolling mills, comprised of rollers that gradually reduce its thickness. During the cold rolling process, the rollers work in pairs, consisting of a work roll and a backup roll. The work roll applies pressure to the strip, while the backup roll provides support and maintains the desired shape. These rolls are typically constructed from high-quality steel or other durable materials capable of withstanding the forces and pressures involved. As the strip progresses through the rolling mills, it experiences successive reductions in thickness. The distance between the rollers diminishes gradually, resulting in compression and elongation of the strip. This reduction in thickness enhances the mechanical properties of the steel, including its strength and hardness. Furthermore, the cold rolling process enhances the surface finish of the steel strip. The pressure applied by the rollers smooths out any surface imperfections and defects, yielding a more uniform and sleeker surface. To ensure precision and consistency, the cold rolling process employs various control systems and measurements. These include gauges and sensors that monitor the dimensions, temperature, and other parameters of the strip as it passes through the rolling mills. In summary, cold rolling is a crucial step in steel strip production. It refines the steel's properties, such as thickness, strength, and surface finish, making it suitable for a diverse range of applications in industries such as automotive, construction, and manufacturing.

- Q: Do steel strips come in different lengths?

- Yes, steel strips do come in different lengths.

- Q: What are the different types of protective coatings for steel strips?

- There are several different types of protective coatings that can be applied to steel strips to enhance their durability and prevent corrosion. These coatings are designed to create a barrier between the steel and the external environment, thereby minimizing the risk of damage and extending the lifespan of the steel strips. Some of the most common types of protective coatings for steel strips include: 1. Paint coatings: These coatings consist of a layer of paint that is applied to the surface of the steel strips. Paint coatings provide a protective barrier against moisture and other corrosive elements, preventing direct contact between the steel and the environment. 2. Galvanized coatings: Galvanizing is a popular method of protecting steel strips from corrosion. This process involves immersing the steel strips in molten zinc, which forms a protective layer of zinc on the surface. Galvanized coatings provide excellent resistance against rust and can withstand harsh environmental conditions. 3. Powder coatings: Powder coatings are applied as a dry powder and then heated to create a protective layer on the steel strips. This type of coating is known for its durability, resistance to chemicals, and excellent adhesion. Powder coatings also offer a wide range of colors and finishes, making them a popular choice for decorative purposes. 4. Epoxy coatings: Epoxy coatings are a type of protective coating that is formed by mixing epoxy resin and a hardening agent. These coatings provide excellent adhesion, chemical resistance, and durability. They are often used in industrial applications where steel strips are exposed to harsh conditions, such as chemical plants or offshore structures. 5. Polyurethane coatings: Polyurethane coatings offer a high level of protection against abrasion, impact, and chemicals. They are commonly used in applications that require a flexible and durable coating, such as automotive parts or machinery components. 6. Ceramic coatings: Ceramic coatings are known for their exceptional resistance to high temperatures and chemical corrosion. These coatings are often used in industries such as aerospace and automotive, where steel strips may be exposed to extreme conditions. It is important to choose the right type of protective coating for steel strips based on the specific requirements and environmental conditions. Factors such as the intended use, exposure to moisture or chemicals, and temperature variations should be considered when selecting the appropriate coating. Consulting with a coatings expert or manufacturer can help determine the best protective coating for the desired application.

- Q: How are steel strips protected against chemicals in industrial environments?

- Steel strips in industrial environments are typically protected against chemicals through the application of protective coatings or treatments. These coatings act as a barrier, preventing direct contact between the steel and the chemicals. Commonly used protective coatings include epoxy, polyurethane, or zinc coatings, which offer resistance to a wide range of chemicals, corrosion, and abrasion. Additionally, proper handling and storage practices are implemented to minimize exposure to chemicals and maintain the integrity of the steel strips.

- Q: How are steel strips used in the production of solar mounting systems?

- Steel strips are used in the production of solar mounting systems for their strength, durability, and flexibility. These strips are often shaped and formed into various components such as brackets, rails, and clamps that provide structural support and secure solar panels in place. The steel strips help in creating a robust and reliable mounting system that can withstand harsh weather conditions while ensuring optimal positioning and stability for the solar panels.

- Q: Can steel strips be bent or formed into different shapes?

- Yes, steel strips can be bent or formed into different shapes through processes such as rolling, bending, or stamping. The malleability and ductility of steel allow it to be easily manipulated into various desired shapes and forms.

- Q: What are the different methods for stamping steel strips?

- There are several methods for stamping steel strips, including progressive stamping, transfer stamping, and compound stamping. Progressive stamping involves feeding the steel strip through a series of dies in a continuous process, gradually shaping and cutting the strip into the desired shape. Transfer stamping, on the other hand, involves transferring the strip from one station to another, allowing for more complex shapes and tighter tolerances. Compound stamping combines elements of both progressive and transfer stamping, utilizing multiple stations to shape and cut the strip. These methods provide flexibility and efficiency in manufacturing various steel strip components.

- Q: How are steel strips cut into specific lengths?

- Steel strips are cut into specific lengths using various methods and tools. One of the most common methods is using a shear, which is a machine specifically designed to cut through metal. The steel strip is placed in the shear, and the shear's blades are then activated to cut through the strip, resulting in the desired length. Another method is using a saw, such as a circular saw or a band saw. These saws are equipped with sharp, toothed blades that can easily cut through steel. The steel strip is secured in place, and the saw is then used to cut through the strip, creating the desired length. Some advanced methods involve using laser cutting or plasma cutting technology. Laser cutting uses a high-powered laser beam to melt or vaporize the steel along the desired cutting line, resulting in a precise and clean cut. Plasma cutting, on the other hand, uses a jet of ionized gas to heat and melt the steel, allowing it to be easily cut into specific lengths. Regardless of the method used, it is crucial to have accurate measurements and precise control over the cutting process to ensure the steel strips are cut into the desired lengths.

- Q: Can steel strips be customized in terms of thickness, width, and length?

- Yes, steel strips can be customized in terms of thickness, width, and length. Customization allows for the production of steel strips that meet specific requirements and applications.

- Q: How do steel strips contribute to improving product performance in various applications?

- There are several ways in which steel strips enhance product performance in various applications. Firstly, their high strength and durability make them ideal for withstanding heavy loads, impact, and wear. By incorporating steel strips, products can be designed to endure harsh conditions and have a longer lifespan. Secondly, the excellent formability and versatility of steel strips allow for the creation of complex and customized products. They can be shaped and molded into different configurations, enabling manufacturers to optimize design and functionality, ultimately resulting in improved product performance. Additionally, steel strips possess exceptional thermal conductivity and electrical resistance properties, making them suitable for applications requiring efficient heat transfer or electrical conduction. Whether in the automotive industry, construction, or electronics, steel strips provide the necessary properties to enhance product performance in these fields. Moreover, steel strips offer corrosion resistance, vital for products exposed to harsh environments or corrosive substances. This characteristic ensures that products maintain their structural integrity and functionality over time, reducing maintenance costs and increasing reliability. Lastly, steel strips contribute to improved product performance by providing a cost-effective solution. Steel is readily available and has relatively low production costs compared to other materials. This affordability allows manufacturers to produce high-quality products at a competitive price, making them accessible to a broader market. In conclusion, steel strips enhance product performance in various applications through their strength, durability, formability, thermal conductivity, corrosion resistance, and cost-effectiveness. Their versatility and reliability make them an excellent choice for manufacturers seeking to enhance their products' performance and longevity.

Send your message to us

Hot Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22223333 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords