Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1.Thickness: 0.14-3.0mm

2.width:30-600mm

3.zinc coating: 30-275g

4.material:Q195, Q235,SGCC, A653 CS-B, DX51D,SGCD,SGHC,S350GD,S450GD,S550GD

5.spangle: zero spangle, regular spangle, small spangle

6.surface treatment: chromated and oiled, chromated and non-oiled

7.packing: export standard packing

8.Payment: TT or L/C

9.MOQ: 25TON

10.coil weight: 3-4ton

11.quality: soft or hard quality

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

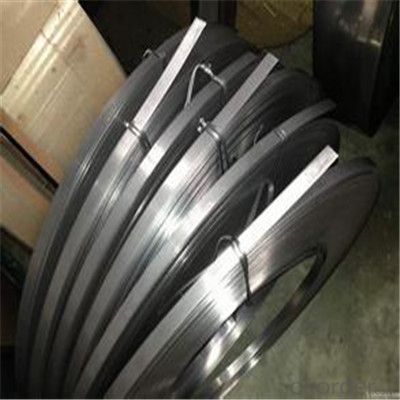

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: Are steel strips used in the aerospace industry?

- Yes, steel strips are commonly used in the aerospace industry. Steel strips are versatile and have excellent mechanical properties, making them suitable for various applications in aerospace manufacturing. They are often used in the construction of aircraft frames, structural components, and wing spars. Steel strips provide strength and rigidity, which are crucial for ensuring the structural integrity and safety of aerospace vehicles. Additionally, steel strips are known for their high resistance to corrosion and temperature variations, making them ideal for use in extreme environmental conditions often encountered in the aerospace industry. Overall, steel strips play a vital role in the aerospace industry and are widely utilized for their durability, strength, and reliability.

- Q: How are steel strips used in the production of surgical instruments?

- Steel strips are used in the production of surgical instruments as they provide the necessary strength, durability, and corrosion resistance required for medical applications. These strips are shaped, cut, and formed into different instrument components such as blades, handles, and hinges. The high-quality steel ensures the instruments remain sharp, sterile, and reliable, enabling surgeons to perform precise procedures with minimal risk of contamination or breakage.

- Q: Are steel strips available in different widths?

- Yes, steel strips are available in different widths.

- Q: How are steel strips used in the production of solar mounting systems?

- Steel strips are an integral component in the production of solar mounting systems due to their strength, durability, and versatility. These strips are often used for various purposes throughout the manufacturing process. Firstly, steel strips are commonly employed in the fabrication of the structural frames of solar mounting systems. These frames serve as the foundation for solar panels, providing stability and support. Steel strips are shaped and formed into the desired frame structure, ensuring it can withstand the weight of the solar panels and withstand environmental conditions such as wind and snow loads. Moreover, steel strips are also utilized in the creation of mounting brackets and rails. These components are responsible for securely fastening the solar panels onto the mounting system. Steel strips are cut and shaped into the required dimensions to form these brackets and rails, ensuring a precise fit and a secure attachment for the solar panels. Furthermore, steel strips are often galvanized or coated with protective layers to enhance their resistance to corrosion and extend their lifespan. This is crucial for solar mounting systems as they are typically exposed to various weather conditions, including rain, humidity, and temperature fluctuations. The protective coating on steel strips ensures that the mounting system can withstand these elements, providing long-lasting support for the solar panels. In summary, steel strips play a vital role in the production of solar mounting systems. They are used to fabricate the structural frames, mounting brackets, and rails, providing strength, durability, and stability to the entire system. With their versatility and resistance to corrosion, steel strips ensure the longevity and reliability of solar mounting systems in harnessing renewable energy from the sun.

- Q: How do steel strips perform in terms of electrical resistance?

- Steel strips have relatively high electrical resistance compared to other metals such as copper or aluminum. This means that they are not as efficient in conducting electricity and can cause higher energy losses.

- Q: How are steel strips used in the production of household tools?

- Due to their durability and strength, steel strips find widespread use in the manufacturing of household tools. These strips serve as raw materials for various tools such as screwdrivers, wrenches, pliers, and hammers. Typically, steel strips are cut into specific lengths and widths before undergoing further processing to shape them into the desired tools. Manufacturers can bend, stamp, or forge these strips to create the necessary components for the tools. For instance, the strips may be bent to form the handles of screwdrivers or pliers, or they may be stamped into the jaws of a wrench. The use of steel strips in tool production offers several advantages. Firstly, steel is a robust material capable of withstanding significant force and pressure, making it ideal for heavily used tools. Secondly, steel exhibits high resistance to corrosion, ensuring that the tools remain in excellent condition even in harsh environments. Moreover, steel strips can be easily molded and shaped, allowing manufacturers to create tools with precise dimensions and intricate designs. This versatility in shaping steel strips enables the production of tools with ergonomic handles, textured surfaces for enhanced grip, and various other features that improve user comfort and efficiency. In conclusion, steel strips play a vital role in the production of household tools, providing durability, strength, and corrosion resistance. Their versatility allows manufacturers to create tools with precise dimensions and designs, resulting in high-quality and dependable products for everyday use.

- Q: Can steel strips be heat-treated?

- Yes, steel strips can be heat-treated. Heat treatment processes such as annealing, tempering, quenching, and hardening can be applied to steel strips to alter their mechanical properties and improve their strength, hardness, and durability.

- Q: How are steel strips used in the production of metal gates?

- Steel strips are commonly used in the production of metal gates due to their strength, durability, and versatility. These thin, flat pieces of steel are typically cut into specific lengths and widths to match the desired dimensions of the gate. One of the main uses of steel strips in gate production is for the fabrication of the gate frame. The strips are often bent or welded together to form a rigid and sturdy framework that provides the gate with structural integrity. The strength of the steel strips ensures that the gate can withstand external forces and remain stable over time. Steel strips are also used for the production of gate panels. These panels are the visible part of the gate and can be designed in various patterns, styles, or even incorporate decorative elements. Steel strips are cut and shaped to form the desired patterns or designs, creating a visually appealing and aesthetically pleasing gate. Additionally, steel strips are used to reinforce the gate, particularly in areas prone to high levels of stress or impact. By strategically placing steel strips within the gate structure, such as at the corners or along the edges, the gate becomes more resistant to bending or warping. This reinforcement helps to maintain the overall shape and functionality of the gate, increasing its longevity and durability. Furthermore, steel strips are often used to attach various components of the gate together. They can be used as connectors, hinges, or brackets, ensuring that all parts of the gate are securely held in place. This improves the overall stability and functionality of the gate, allowing it to open and close smoothly. In summary, steel strips play a crucial role in the production of metal gates. They are used to create the gate frame, panels, reinforcement, and as connectors, providing strength, durability, and stability to the finished product.

- Q: Are steel strips suitable for making utensils?

- Yes, steel strips are suitable for making utensils. Steel is a durable and versatile material that is commonly used in the manufacturing of various kitchen utensils. Steel strips are often used to create the blades of knives, as well as the bodies of other utensils such as spoons, forks, and tongs. Steel is highly resistant to corrosion, which makes it ideal for utensils that come into contact with food and liquids. Additionally, steel provides a smooth and polished surface that is easy to clean and maintain. Overall, steel strips are a reliable and suitable choice for making utensils due to their strength, durability, and hygienic properties.

- Q: How are steel strips used in the production of HVAC ductwork?

- Steel strips are used in the production of HVAC ductwork as they are rolled and formed into specific shapes to create the structure of the ducts. These strips are then welded or joined together to form a strong and durable duct system that can efficiently transport air throughout buildings.

Send your message to us

Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords