Hot and Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil, kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware, vehicles

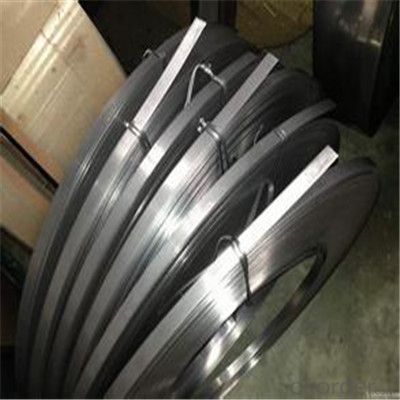

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: What are the main applications of steel strips?

- Steel strips are widely used in various industries for multiple applications. Some of the main applications of steel strips include manufacturing of automotive components, electrical appliances, construction materials, and packaging materials. They are also used in the production of pipes, tubing, and metal stamping applications. Additionally, steel strips are utilized in the production of household goods, furniture, and in the aerospace industry.

- Q: What is the difference between carbon steel and stainless steel strips?

- Carbon steel and stainless steel strips are both types of steel, but they differ in terms of their composition, properties, and applications. One major difference between carbon steel and stainless steel strips is their composition. Carbon steel is primarily made of iron and carbon, with trace amounts of other elements. Stainless steel, on the other hand, contains iron, chromium, and varying amounts of other elements such as nickel, manganese, and molybdenum. The presence of chromium in stainless steel provides it with corrosion resistance properties, which carbon steel lacks. The second difference lies in their properties. Carbon steel strips are strong and durable, making them suitable for applications that require high strength, such as construction, automotive, and machinery industries. However, carbon steel is prone to rust and corrosion in the presence of moisture and certain chemicals. Stainless steel strips, with their higher chromium content, offer excellent corrosion resistance. They are less prone to rust and staining, making them ideal for applications in environments with high moisture levels or exposure to corrosive substances. Stainless steel also has a higher tensile strength than carbon steel, making it more resistant to wear and tear. Lastly, the applications of carbon steel and stainless steel strips differ due to their properties. Carbon steel strips are commonly used in manufacturing components for infrastructure, automotive parts, tools, and machinery. They are also widely used in construction, as they are strong and cost-effective. Stainless steel strips, with their corrosion resistance properties, find applications in various industries such as food processing, pharmaceuticals, chemical processing, and medical equipment manufacturing. They are also commonly used in architectural applications, kitchen utensils, and decorative items due to their aesthetic appeal and durability. In summary, the main difference between carbon steel and stainless steel strips lies in their composition, properties, and applications. Carbon steel is strong but prone to rust, while stainless steel offers corrosion resistance and higher tensile strength. The choice between the two depends on the specific requirements of the intended application.

- Q: How are steel strips used in the production of air conditioning systems?

- Steel strips are used in the production of air conditioning systems in various ways. One of the primary uses is for the construction of the outer casing or housing of the air conditioning unit. The steel strips are formed into panels or sheets that provide a durable and protective covering for the internal components of the system. Additionally, steel strips are often used in the manufacturing of the heat exchangers, which are crucial components in air conditioning systems. The heat exchangers are responsible for transferring heat between the indoor and outdoor environments, allowing the air conditioning unit to cool or heat the air as required. Steel strips are used to create the finned surfaces of the heat exchangers, which maximize the surface area available for heat transfer. Furthermore, steel strips are also utilized in the fabrication of various brackets, supports, and frames within the air conditioning system. These components provide structural stability and ensure the proper positioning and alignment of the different parts of the unit. Steel's strength and rigidity make it an ideal material for these applications. In summary, steel strips play a vital role in the production of air conditioning systems. They are used for the construction of the outer casing, the manufacturing of heat exchangers, and the fabrication of various brackets and supports. The use of steel in these applications ensures the durability, efficiency, and overall performance of air conditioning units.

- Q: How do steel strips handle exposure to UV radiation?

- Steel strips are typically resistant to UV radiation and can handle exposure to it without significant degradation or damage. However, over prolonged periods of exposure, some steel strips may experience slight discoloration or surface oxidation. To minimize any potential effects, protective coatings or treatments can be applied to enhance their resistance to UV radiation.

- Q: How are steel strips tested for decarburization?

- To ensure the quality and integrity of steel strips, various methods are utilized to test for decarburization. Visual inspection is a common approach, involving the examination of the strip's surface for signs like discoloration or roughness. This inspection can be done manually or with automated systems. Another method, known as microhardness testing, measures the strip's hardness at different depths. Since decarburization usually leads to decreased hardness, comparing hardness values at various depths allows for an assessment of the extent of decarburization. Chemical analysis is also employed to determine the carbon content of the strip. Decarburization involves carbon loss from the surface layer, so comparing carbon content at different depths provides insight into the degree of decarburization. Metallographic examination is an additional technique for decarburization testing. This entails preparing a cross-section of the strip and examining it under a microscope. The presence and thickness of a decarburized layer can be observed, allowing for an evaluation of the depth and severity of decarburization. Non-destructive testing methods like ultrasonic or eddy current testing can be utilized as well. These methods utilize sound waves or electromagnetic fields to identify irregularities or changes in the strip's composition, aiding in the detection and assessment of decarburization. In summary, a comprehensive approach to testing steel strips for decarburization involves a combination of visual inspection, microhardness testing, chemical analysis, metallographic examination, and non-destructive testing. This ensures that the material meets the necessary standards and is suitable for its intended application.

- Q: How are steel strips used in the production of wire and cable?

- Steel strips serve as a vital core material in the manufacturing of wire and cable. These strips are typically crafted from robust, high-quality steel, known for its strength and durability. They are usually thin and flat, forming a coiled or wound structure on a spool. To shape the steel strips, they undergo a manufacturing process involving the creation of a specific size and shape. This can be achieved through various methods, such as cold rolling or hot rolling. Cold rolling entails passing the steel strip through a sequence of rollers at room temperature, while hot rolling involves heating the strip before passing it through the rollers. These shaping techniques ensure that the steel strip attains the necessary dimensions and properties required for wire and cable production. After the formation of the steel strips, a protective layer of corrosion-resistant material is typically applied. This coating safeguards the steel from moisture and other environmental elements that may cause rust or deterioration. The coating may consist of different materials, including zinc, tin, or polymer-based compounds. The coated steel strips are then utilized as the core material in the manufacturing of wire and cable. They are commonly positioned at the center of the wire or cable, providing structural support and strength. The steel strip core aids in maintaining the wire or cable's shape and resisting stretching or breaking when subjected to tension. Moreover, the steel strips contribute to the electrical conductivity of the wire or cable. Steel possesses excellent conductivity, and the presence of a steel strip core can enhance the overall conductivity of the wire or cable. In summary, steel strips play a critical role in the production of wire and cable by offering strength, durability, and electrical conductivity to the final product.

- Q: What are the safety considerations when handling steel strips?

- There are several crucial safety considerations to bear in mind when dealing with steel strips. Firstly, it is essential to wear the proper personal protective equipment (PPE) like gloves and safety glasses to safeguard against cuts and the potential for debris to fly. Moreover, it is important to apply correct lifting techniques to avoid back injuries, as steel strips can be heavy and sharp. Another point to consider is the likelihood of steel strips having sharp edges or burrs. To prevent cuts or punctures, it is imperative to examine the strips for any sharp or jagged edges before handling them. If any defects are detected, the strips should be adequately deburred or filed down to eliminate any hazards. In addition, steel strips can become slippery, particularly if they are coated or have oils on them. Hence, it is crucial to maintain a clean and dry working area to prevent slipping and falling. If necessary, anti-slip mats or suitable footwear should be utilized to enhance traction and stability. Finally, when handling steel strips, it is vital to be mindful of the potential hazards associated with their storage and transportation. To prevent workers from being harmed by falling or rolling strips, they must be stored securely and in an organized manner. Furthermore, during transportation, steel strips should be appropriately secured to prevent any movement or shifting. Overall, the safety considerations pertaining to steel strip handling revolve around the utilization of appropriate PPE, the implementation of proper lifting techniques, the inspection of sharp edges, the maintenance of a clean work environment, and the assurance of secure storage and transportation. By adhering to these safety measures, the risk of injuries and accidents related to steel strip handling can be significantly minimized.

- Q: Can steel strips be used for making springs in automotive suspension systems?

- Yes, steel strips can be used for making springs in automotive suspension systems. Steel is a commonly used material for springs due to its strength, durability, and ability to withstand heavy loads. Steel strips can be manufactured into various types of springs, including coil springs and leaf springs, which are commonly used in automotive suspension systems. These springs help absorb shocks and vibrations, providing a smooth and stable ride for the vehicle. Steel strips can be heat-treated and shaped into the desired form to meet the specific requirements of the suspension system, ensuring optimal performance and longevity. Moreover, steel strips are readily available, cost-effective, and widely used in the automotive industry, making them an ideal choice for making springs in automotive suspension systems.

- Q: How do steel strips perform in terms of sound damping?

- Steel strips generally have poor sound damping properties. Due to their rigid and dense nature, they are not effective in reducing or absorbing sound vibrations.

- Q: How are steel strips stamped or formed into specific shapes?

- Steel strips are typically stamped or formed into specific shapes using a variety of techniques such as pressing, rolling, bending, or coiling. These processes involve applying pressure or force onto the steel strips, either mechanically or through hydraulic systems, to reshape them into the desired configuration.

Send your message to us

Hot and Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords