Hot Rolled Steel Strip Coils Q195 Q235 from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 344 m.t.

- Supply Capability:

- 2222454 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

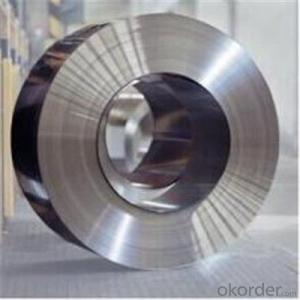

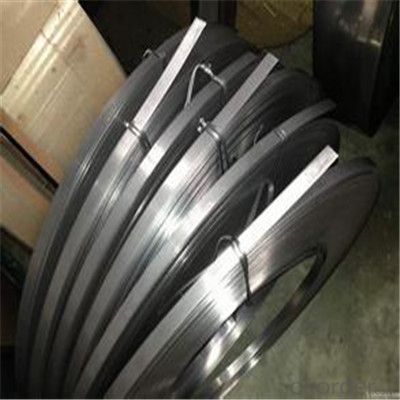

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips supplied to customers?

- Customers typically receive steel strips through various methods, with one common approach being through steel service centers or distributors. These centers or distributors obtain steel strips in large quantities directly from steel mills or manufacturers, and then process and distribute them to customers based on their specific needs. The steel strips are generally supplied in tightly wound coils, which can vary in size and weight depending on customer requirements. These coils are stored in warehouses or storage facilities until customers place orders. When a customer submits an order, the steel service center or distributor retrieves the necessary coil from their inventory. The steel strips can be supplied in different forms, depending on the customer's preferences and logistical needs. They can be cut to specific lengths, slit into narrower strips, or leveled and flattened to ensure uniformity and precision. The steel strips are then securely packaged to protect them during transportation. Depending on the size and weight of the coils, they may be shipped by truck, rail, or even by sea for international customers. The coils are typically stacked and secured on pallets or loaded directly onto flatbed trucks or shipping containers. In addition to steel service centers, some manufacturers may also directly supply steel strips to their customers. This is more common for large-scale projects or when customers have specific requirements that can be better met by working directly with the manufacturer. Overall, the supply of steel strips to customers involves a well-coordinated process involving steel mills, service centers or distributors, and transportation logistics to ensure the timely and efficient delivery of the steel strips to customers.

- Q: Can steel strips be heat treated to improve their properties?

- Yes, steel strips can be heat treated to improve their properties. Heat treatment is a process that involves heating and cooling steel in a controlled manner to alter its physical and mechanical properties. This can be done to enhance the steel's hardness, strength, toughness, and resistance to wear or corrosion. There are various heat treatment methods used for steel strips, including annealing, quenching, tempering, and case hardening. Annealing involves heating the steel to a specific temperature and then slowly cooling it to relieve internal stresses and improve its ductility. Quenching, on the other hand, involves rapidly cooling the steel after heating it, which increases its hardness and strength. Tempering is a process that follows quenching and involves reheating the steel to a specific temperature and then cooling it again to reduce its brittleness and increase its toughness. Case hardening is another heat treatment technique used for steel strips, where the surface layer of the steel is hardened to improve wear resistance, while the core remains relatively softer to retain toughness. This is achieved by introducing carbon or nitrogen into the surface layer and then heating and cooling the steel. Overall, heat treatment is a crucial process in the production of steel strips as it allows manufacturers to tailor the material's properties to specific applications. By carefully controlling the heating and cooling processes, steel strips can be optimized for strength, hardness, ductility, and other desired characteristics.

- Q: What are the main factors affecting the thermal conductivity of steel strips?

- The main factors affecting the thermal conductivity of steel strips are the chemical composition of the steel, the presence of impurities or alloying elements, the crystal structure and grain orientation of the steel, and the temperature at which the steel is being measured.

- Q: How do steel strips respond to different heat treatment processes?

- Steel strips respond differently to different heat treatment processes. Heat treatment processes such as annealing, quenching, tempering, and normalizing can significantly alter the properties of steel strips. Annealing is a heat treatment process that involves heating the steel strips to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, improve ductility, and refine the grain structure of the steel. As a result, annealed steel strips become softer, more malleable, and less brittle. Quenching, on the other hand, involves rapidly cooling the steel strips after heating them to a critical temperature. This process causes the formation of a hardened microstructure, making the steel strips very hard and brittle. Quenched steel strips are often used in applications that require high hardness and wear resistance, such as cutting tools. Tempering is a heat treatment process that follows quenching. It involves reheating the hardened steel strips to a specific temperature and then cooling them at a controlled rate. Tempering reduces the brittleness of the steel, making it tougher and more ductile. This process helps to balance the hardness and toughness of the steel strips, making them suitable for applications such as springs and gears. Normalizing is a heat treatment process similar to annealing, but the cooling rate is faster. It is often used to refine the grain structure of the steel strips and improve their mechanical properties. Normalized steel strips have improved strength and toughness, making them suitable for applications that require high strength and impact resistance. Overall, the response of steel strips to different heat treatment processes depends on the specific process used, the temperature, and the cooling rate. Each heat treatment process can modify the microstructure and properties of the steel strips, allowing them to be customized for various applications.

- Q: Can steel strips be used for making medical devices or implants?

- Yes, steel strips can be used for making medical devices or implants. Steel is a commonly used material in the medical industry due to its high strength, durability, and resistance to corrosion. Steel strips can be shaped, molded, or machined into various medical devices and implants, such as surgical instruments, orthopedic implants, and cardiovascular stents. However, the specific type of steel and its composition must meet the required standards and regulations to ensure biocompatibility and safety for use in medical applications.

- Q: How are steel strips processed for perforating?

- Steel strips are processed for perforating by passing them through a specialized machine that uses a combination of pressure and sharp tools to create evenly spaced holes or perforations on the surface of the strip. This process allows for the customization of the strip's design and enables it to be used in various applications such as filtration, ventilation, or decorative purposes.

- Q: What are the typical dimensions of steel strips?

- The typical dimensions of steel strips can vary depending on the specific application and industry, but they are commonly available in thicknesses ranging from 0.1mm to 6mm and widths ranging from 10mm to 1500mm.

- Q: What are the future trends in steel strip manufacturing?

- Some future trends in steel strip manufacturing include the adoption of advanced automation and robotics technology to enhance production efficiency and reduce costs. Additionally, there is a growing focus on sustainable manufacturing practices, such as using recycled materials and implementing green energy solutions. Industry 4.0 technologies, such as the Internet of Things (IoT) and big data analytics, will also play a significant role in optimizing operations and improving quality control. Furthermore, there is a shift towards developing high-strength steel strips to meet the increasing demand for lightweight materials in sectors like automotive and aerospace.

- Q: What are the quality control measures for steel strips manufacturing?

- Quality control measures for steel strip manufacturing typically include: 1. Raw material inspection: Ensuring that the steel used meets the required specifications and is free from defects. 2. Continuous monitoring: Regularly checking the production process to identify any deviations or abnormalities that could affect the quality of the steel strips. 3. Dimensional checks: Verifying the dimensions of the steel strips against the specified tolerances to ensure they meet the required standards. 4. Surface inspection: Examining the surface of the strips for any defects, such as scratches, dents, or corrosion. 5. Mechanical properties testing: Conducting tests to assess the strength, hardness, and other mechanical properties of the steel strips, ensuring they meet the desired standards. 6. Coating inspection: If applicable, inspecting the coating on the steel strips to ensure it is evenly applied and adheres properly. 7. Packaging and labeling: Checking that the steel strips are packaged correctly and labeled accurately, with proper identification and necessary documentation. 8. Statistical process control: Implementing statistical techniques to monitor and control the quality of the manufacturing process, identifying any trends or variations that may impact the final product. Overall, these quality control measures help ensure the production of high-quality steel strips that meet the required standards and customer expectations.

- Q: What are the packaging requirements for transporting steel strips?

- When transporting steel strips, there are several packaging requirements in place to ensure their safety and prevent any damage during transit. These requirements include: 1. Proper wrapping: Steel strips should be securely wrapped with suitable materials, such as plastic or shrink wrap, to prevent any movement or shifting during transportation. This helps to protect the strips from scratches, dents, or other physical damage. 2. Reinforced packaging: Depending on the size and weight of the steel strips, additional reinforcement may be required. This can be done by using wooden or metal pallets, corner protectors, or strapping to provide stability and prevent any bending or warping. 3. Adequate cushioning: To further protect the steel strips from impact, cushioning materials such as foam or bubble wrap should be used. These materials absorb shocks and vibrations during transport, reducing the risk of any damage caused by sudden movements or impacts. 4. Proper labeling: Clear and visible labeling is crucial when transporting steel strips. Labels should include information such as the type of steel, dimensions, weight, and any special handling instructions. This ensures that the package is handled correctly throughout the transportation process. 5. Moisture protection: Steel strips are susceptible to rust and corrosion, especially if exposed to moisture. Therefore, packaging materials should be moisture-resistant, and additional measures like adding desiccants or using moisture barrier films can be taken to protect the steel strips from humidity. 6. Compliance with regulations: It is important to ensure that the packaging of steel strips complies with the relevant regulations and guidelines, such as those set by international shipping organizations or local authorities. This includes regulations on weight limits, hazardous materials, and securing methods. By following these packaging requirements, the risk of damage to steel strips during transportation can be minimized, ensuring that they arrive at their destination in optimal condition.

Send your message to us

Hot Rolled Steel Strip Coils Q195 Q235 from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 344 m.t.

- Supply Capability:

- 2222454 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords