Hot and Cold Carbon Rolled Steel Strip Coils Q195 Q235

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Our products mainly used in Construction area, Industry area,kitchen tools and medical tools and so on.Construction area: putty knife, plastering trowel, long handle putty knife, bricklaying trowel ect.Industry area : car pares, knife parts, barral parts, band saw blade, electric machine parts and so on. Kitchen; knife, food container, pot, scraper, bottle, kettle cover, ect.The producets also used in medical, shoe making and other area

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

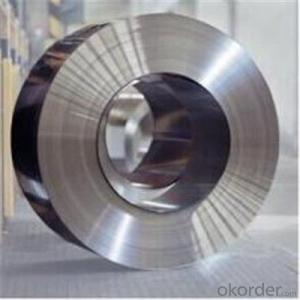

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: What are the common challenges in manufacturing steel strips?

- Some common challenges in manufacturing steel strips include ensuring consistent thickness and width throughout the strip, preventing surface defects such as scale and scratches, maintaining proper flatness and straightness, achieving desired mechanical properties, and managing temperature control during the manufacturing process. Additionally, quality control and ensuring compliance with industry standards and customer specifications are also important challenges in steel strip manufacturing.

- Q: Is the strip steel strip?

- Some thicker medium plate production is not produced by strip steel. In any case, the strip is a general term for strip and plate.

- Q: What are the common thickness variations in steel strips?

- The common thickness variations in steel strips can vary depending on the specific industry and application. However, in general, steel strips are typically manufactured with a tolerance range for thickness to account for variations during the production process. The most common thickness variations in steel strips are typically measured in terms of the gauge or thickness range. The gauge of a steel strip refers to its thickness, with lower gauge numbers indicating thicker strips and higher gauge numbers indicating thinner strips. For example, in the automotive industry, steel strips used for structural components may have a thickness variation tolerance of ±0.005 inches (0.13 mm) or less. This ensures that the strips meet the required strength and performance specifications while maintaining consistency in the manufacturing process. In other industries, such as construction or manufacturing, steel strips may have slightly larger thickness variations depending on the application. Thickness variations in these cases can range from ±0.010 inches (0.25 mm) to ±0.020 inches (0.51 mm) or more, depending on the specific requirements of the project. It is important to note that these thickness variations are carefully controlled and specified by industry standards and regulations. Manufacturers use advanced technology and quality control measures to ensure that steel strips are produced within the required tolerance range to meet the desired specifications. Overall, while there may be some slight thickness variations in steel strips, they are typically controlled within specific tolerance ranges to ensure consistency, quality, and performance in various applications.

- Q: What are the different widths and thicknesses of steel strips available?

- The widths and thicknesses of steel strips available vary depending on the specific requirements and applications. Common widths for steel strips can range from as narrow as 0.5 inches (12.7 mm) to as wide as 60 inches (1524 mm) or even more. Similarly, the thicknesses can vary from thin gauges, such as 0.001 inches (0.0254 mm), to heavy gauges exceeding 1 inch (25.4 mm). However, it's important to note that the exact range of widths and thicknesses can be further expanded or limited based on the specific steel supplier and manufacturing capabilities.

- Q: How are steel strips used in the pharmaceutical industry?

- Steel strips are commonly used in the pharmaceutical industry for packaging medicines in the form of blister packs. These strips provide a sturdy and protective barrier, ensuring the integrity and safety of the medication. Additionally, steel strips are also used for sealing pharmaceutical bottles, ensuring airtight packaging to maintain the quality and freshness of the products.

- Q: Are steel strips used in the production of metal brackets and supports?

- Yes, steel strips are commonly used in the production of metal brackets and supports. Steel strips provide strength, durability, and stability to these components. They are often used in applications where high load-bearing capacity is required. Steel strips can be easily shaped, cut, and welded, making them suitable for various bracket and support designs. Additionally, steel strips have excellent resistance to corrosion, making them ideal for outdoor or harsh environment applications.

- Q: Are steel strips used in the manufacturing of household appliances?

- Yes, steel strips are commonly used in the manufacturing of household appliances. Steel is a preferred material due to its strength, durability, and resistance to corrosion. Steel strips are often used for the outer casing or body of appliances such as refrigerators, ovens, dishwashers, and washing machines. These strips provide structural support and help protect the internal components of the appliances. Additionally, steel strips can be easily shaped and formed into different sizes and designs, making them versatile for various appliance models. The use of steel strips ensures that household appliances are sturdy, long-lasting, and able to withstand the demands of everyday use.

- Q: Are steel strips suitable for the manufacturing of safety equipment?

- Yes, steel strips are suitable for the manufacturing of safety equipment. Steel is a durable and strong material that can provide the necessary structural integrity and protection required for safety equipment. Its high strength-to-weight ratio and resistance to impact make it an ideal choice for manufacturing safety equipment such as helmets, protective shields, and body armor. Additionally, steel's corrosion resistance properties ensure the longevity and reliability of the safety equipment, making it a suitable material for such applications.

- Q: Are steel strips suitable for low-temperature applications?

- Yes, steel strips are suitable for low-temperature applications. Steel is known for its excellent strength and durability, which makes it a suitable material for low-temperature environments where other materials may become brittle or lose their structural integrity. Additionally, steel can withstand extreme cold temperatures without compromising its mechanical properties, making it an ideal choice for various low-temperature applications such as in cryogenic industries, refrigeration systems, and cold storage facilities.

- Q: How are steel strips stamped or formed into specific shapes?

- Various manufacturing processes can be used to transform steel strips into specific shapes. One commonly used method is stamping or pressing, where the steel strip is placed between two dies. Pressure is then applied to deform the strip into the desired shape. The dies have cavities that match the shape of the final product, and when the strip is pressed between them, it takes on the shape of the cavities. Stamping can be done using mechanical or hydraulic presses. Mechanical presses use a motor-driven flywheel to generate energy, while hydraulic presses use fluid pressure. Each type of press has its own advantages depending on the complexity and size of the desired shape. Typically, the steel strip is fed into the press and the press is activated. This causes the dies to come together and shape the strip. The process can be done in a single step or multiple steps depending on the complexity of the shape. Multiple steps may involve multiple dies and intermediate operations to gradually shape the strip into the final product. Another method for shaping steel strips is roll forming. In this process, the strip is passed through a series of rollers that progressively bend and shape it. Each roller contributes to a specific part of the final shape. The strip is continuously fed through the rollers until the desired shape is achieved. Roll forming is advantageous for producing long, continuous shapes or profiles used in construction or automotive industries. It offers high precision and repeatability, making it suitable for mass production. In conclusion, pressure, bending, and manipulation of steel strips using specialized dies or rollers allow for the efficient and precise production of a wide range of steel products with different shapes and sizes, whether through stamping or roll forming.

Send your message to us

Hot and Cold Carbon Rolled Steel Strip Coils Q195 Q235

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords