Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.tungsten, carbon and so on. Basically, steel is an iron-carbon alloy that does not undergo eutectic reaction. In contrast,cast iron does undergo eutectic reaction, juveniles and non-breeding males have predominantly grey-brown plumage, but breeding males adopt brilliant colours, with an iridescent silvery-blue crown and upper back, red-brown shoulders, a black throat, grey-brown wings and pale underparts. Though the red-winged fairywren is locally common, there is evidence of a decline in numbers. Primarily insectivorous, it forages and lives in the shelter of scrubby vegetation in China.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

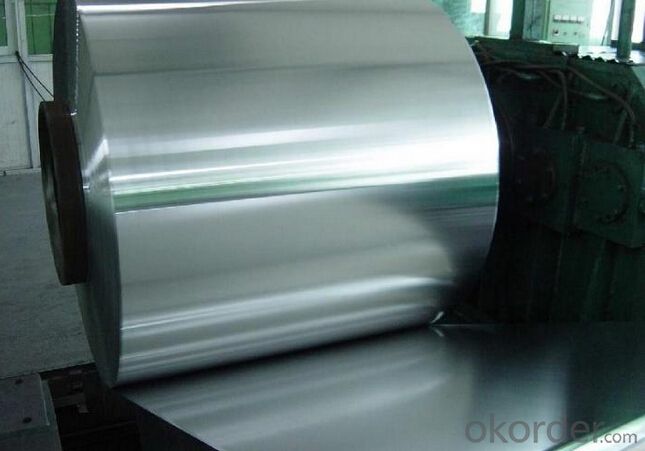

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the main factors affecting the thermal conductivity of steel strips?

- The main factors affecting the thermal conductivity of steel strips are the chemical composition of the steel, the presence of impurities or alloying elements, the crystal structure and grain orientation of the steel, and the temperature at which the steel is being measured.

- Q: What are the different types of heat treatments for steel strips?

- There are several different types of heat treatments that can be applied to steel strips to enhance their properties and meet specific requirements. Some of the common heat treatments for steel strips include: 1. Annealing: This process involves heating the steel strips to a high temperature and then slowly cooling them, usually in a controlled atmosphere. Annealing helps to relieve internal stresses, improve machinability, and enhance the ductility and toughness of the steel. 2. Hardening: Hardening is a heat treatment technique that involves heating the steel strips to a high temperature and then rapidly cooling them, typically using quenching in oil or water. This process increases the hardness and strength of the steel, making it suitable for applications where wear resistance and durability are crucial. 3. Tempering: Tempering is often performed after the hardening process. It involves heating the hardened steel strips to a lower temperature and then slowly cooling them. This treatment helps to reduce the brittleness caused by the hardening process and improves the toughness and ductility of the steel. 4. Normalizing: Normalizing is a heat treatment method similar to annealing, but with a faster cooling rate. The steel strips are heated to a temperature slightly above the critical point and then cooled in still air. Normalizing helps to refine the grain structure, improve the overall mechanical properties, and enhance the machinability of the steel. 5. Stress relieving: This heat treatment is performed to relieve the internal stresses that can develop during manufacturing processes such as cutting, bending, or welding. The steel strips are heated to a specific temperature and then slowly cooled. Stress relieving helps to prevent distortion or cracking and improves dimensional stability. 6. Case hardening: Case hardening is a surface treatment method that aims to increase the hardness and wear resistance of the outer layer of the steel strips while maintaining a tough and ductile core. This is achieved by heating the steel strips in the presence of a carbon-rich atmosphere or by introducing carbon-rich compounds onto the surface and then quenching them. 7. Solution annealing: This treatment is primarily used for stainless steel strips. It involves heating the steel strips to a high temperature followed by rapid cooling to dissolve any carbides or other precipitates. Solution annealing helps to restore the corrosion resistance and mechanical properties of stainless steel. These are just a few examples of the various heat treatments available for steel strips. The choice of heat treatment depends on the specific requirements of the application and desired properties of the steel.

- Q: What are the common painting techniques for steel strips?

- There are several common painting techniques that can be used for steel strips. The most commonly used technique is the spray painting method. This involves using a spray gun to evenly distribute paint onto the surface of the steel strip. This technique is highly efficient and provides a smooth and even finish. Another commonly used technique is brush painting. This involves using a paintbrush to manually apply paint onto the steel strip. Brush painting is often used for smaller areas or intricate designs where precision is required. Electrostatic painting is another popular technique for painting steel strips. This method involves applying an electrostatic charge to the paint particles, which are then attracted to the grounded steel strip. This technique provides a highly uniform and durable finish. Powder coating is also commonly used for steel strips. In this method, a dry powdered paint is applied to the steel strip. The strip is then heated, causing the powder to melt and form a smooth and durable coating. Powder coating is known for its excellent resistance to chipping, scratching, and fading. Lastly, immersion painting is a technique where the steel strip is submerged in a tank of paint. This method is often used for large-scale projects where efficiency is important. The steel strip is completely coated in paint and then removed from the tank to dry. Overall, the choice of painting technique for steel strips depends on various factors such as the size of the project, desired finish, and efficiency requirements. Each technique has its own advantages and can produce high-quality results when used appropriately.

- Q: What is the typical wear resistance of steel strips?

- The wear resistance of steel strips can differ based on various factors, including the type of steel, steel hardness, surface treatment, and specific usage. Nonetheless, steel strips are generally recognized for their superior wear resistance in comparison to other materials. Industries that necessitate materials with exceptional wear and abrasion resistance, such as automotive, construction, mining, and manufacturing, often employ steel strips. The wear resistance of steel strips is mainly attributed to their hardness, which is usually achieved through heat treatment or alloying. Steel strips with higher hardness typically exhibit better wear resistance. The wear resistance of steel strips can be further enhanced by applying diverse surface treatments or coatings. For instance, the application of hard chrome plating or a diamond-like carbon (DLC) coating can substantially improve the wear resistance of steel strips, prolonging their lifespan and performance in challenging applications. It is crucial to note that the typical wear resistance of steel strips can vary depending on the specific application and the involved wear mechanisms. Factors such as the type of abrasives, sliding speed, and contact pressure can impact the wear behavior of steel strips. Therefore, it is essential to consider these factors and select the appropriate steel grade or surface treatment to ensure optimal wear resistance in a given application.

- Q: What are the specifications for steel strips used in the production of razor blades?

- The specifications for steel strips used in the production of razor blades typically include high carbon content, precise thickness ranging from 0.1mm to 0.3mm, uniform hardness, and a polished surface finish for sharpness and durability. Additionally, the steel should have excellent tensile strength and be resistant to corrosion and wear.

- Q: What are the different surface deburring techniques for steel strips?

- There are several surface deburring techniques for steel strips, including manual deburring, mechanical deburring, and chemical deburring. Manual deburring involves using hand tools such as files, sandpaper, or abrasive pads to remove burrs. Mechanical deburring uses machines equipped with brushes, belts, or grinding wheels to achieve the same result. Chemical deburring involves immersing the steel strips in a chemical solution that dissolves the burrs. Each technique has its advantages and is chosen based on the specific requirements and constraints of the project.

- Q: What is the corrosion resistance of steel strips?

- The corrosion resistance of steel strips can vary depending on the specific type of steel used and the environmental conditions they are exposed to. Generally, steel strips are known for their good resistance to corrosion due to the presence of iron, which naturally reacts with oxygen to form a protective layer of iron oxide or rust. However, this protective layer can be compromised in certain corrosive environments, such as those high in moisture, salt, or acidic substances. To improve corrosion resistance, steel strips can be coated with materials like zinc, aluminum, or other alloys that provide an additional barrier against corrosion. Additionally, proper maintenance and regular inspections are crucial to prevent and address any signs of corrosion in steel strips.

- Q: What are the different surface defects found in steel strips?

- There are several different surface defects that can be found in steel strips. Some of the common defects include: 1. Scale: Scale is a form of oxide that forms on the surface of steel when it is exposed to high temperatures. It appears as a thin layer of flaky material and can affect the appearance and quality of the steel. 2. Roll marks: Roll marks are caused by irregularities on the rolls used to flatten the steel during the manufacturing process. They appear as raised or depressed areas on the surface of the steel and can affect its flatness and appearance. 3. Scratches: Scratches are caused by mechanical damage to the surface of the steel, such as during handling or transportation. They can vary in size and depth and can affect the appearance and integrity of the steel. 4. Pits: Pits are small depressions or cavities in the surface of the steel. They can be caused by various factors, including corrosion, handling damage, or manufacturing defects. Pits can affect the appearance and structural integrity of the steel. 5. Edge cracks: Edge cracks are cracks that occur along the edges of the steel strip. They can be caused by various factors, including improper handling, overloading, or manufacturing defects. Edge cracks can affect the strength and integrity of the steel. 6. Surface contamination: Surface contamination refers to the presence of foreign materials on the surface of the steel, such as oil, grease, dirt, or paint. Contamination can affect the surface quality and may also lead to corrosion or other forms of damage. It is important to detect and address these surface defects in steel strips to ensure the quality and performance of the steel. Various inspection and quality control measures, such as visual inspection, non-destructive testing, and surface treatment techniques, are employed to identify and rectify these defects before the steel is used in various applications.

- Q: Can steel strips be used in the production of metal roofing panels?

- Yes, steel strips can be used in the production of metal roofing panels. Steel strips are commonly used as the base material for metal roofing panels due to their durability, strength, and resistance to corrosion. They are typically coated with materials like zinc or aluminum to further enhance their protective properties. This process ensures that the metal roofing panels have a long lifespan and can withstand various weather conditions, making them a popular choice for residential and commercial buildings.

- Q: What are the different surface plating options for steel strips?

- There are several surface plating options available for steel strips, including zinc plating, nickel plating, chrome plating, tin plating, and copper plating. Each option provides unique benefits such as corrosion resistance, improved aesthetics, enhanced conductivity, or increased durability, allowing for customization based on the specific requirements and applications of the steel strips.

Send your message to us

Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords