Hot-dip Zinc Coating Steel Building Roof Walls ASTM A562

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3434 unit

- Supply Capability:

- 45343 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.The coil coating process may be used for other substrates such as aluminium, or aluminium, stainless steel or alloy coated steel other than "pure" zinc coated steel. However, only "pure" zinc coated steel is typically referred to as PPGI. For example PPGL may be used for pre-painted 55%Al/Zn alloy-coated steel (pre-painted GALVALUME(r) steel*)

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

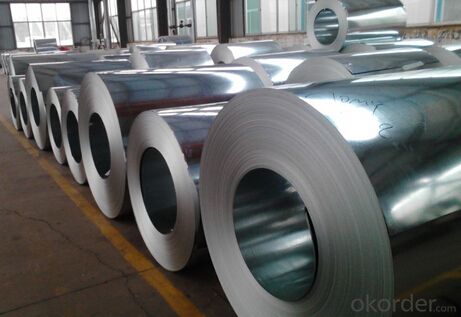

3.Hot-Dip Galvanized Steel Sheet Images

2.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the function of the tractor?

- The function of the tractor is always to provide a more powerful power output to solve the daily labor in the dynamic demand.

- Q: What kind of single tractor in the stock list?

- Under the funds account, you can at different prices with different shareholder code, while buying (selling) a stock, which is inherently a way of confidentiality, and therefore to know exactly who to buy (sell

- Q: What are the tes on the tractor

- In cars, the efficiency of the engine and the vehicle is very strong. If the engine of a small engine does not fit well, it is likely to be no more fuel-efficient than a large engine, or even more than a large engine. Especially the weight of the heavier car, if the engine displacement is too small, with a small cart, must make the engine more running under the high speed heavy load, so as to consume more gasoline. If it is a large engine, it doesn't have to go deep into the gas pedal because of the greater torque, so the amount of gasoline consumed is not much change. Compared with the results, is likely to be smaller more fuel engine Read the secret behind the rear of the car: T is the Turbo Turbo L extended edition GLS is generally refers to the vehicle type of SANTANA 2000 initial model It is carburetor type GLI is efi BMW750i efi mean's that I CVL and infinitely variable speed is T manual, ABS is equipped with anti-lock braking system is A after the digital automatic transmission, A in front of the Numbers is refers to the transmission, such as the audi A6 second 2 d four door three 3 d 4 d five 5 d hatchback HB wagon W (Wag - On) Coupe C (Coupe) four-door sports car S (sedan) top four-door sports car C (Convertible Coupe) super luxury sedan Limousine

- Q: What is the reason for the abrasion of a tractor

- Front wheel toe-in improper adjustment, the main reason is that the hollow shaft and shaft bushing wear before the clearance is too large, hollow shaft and bushing forging is easy to wear. When l this material set of wear l, big intervals between the front wheel toe-in value change, accelerate the wear of front wheel.

- Q: APP store in the tractor game is the highest popularity which 20 it

- You are asked to ask people, and I like to upgrade the tractor to play the game, before they are playing on the computer to play the joy of QQ upgrade, and now generally in the mobile phone to play the Caesar, the Internet under several upgrades, is simply dead fish

- Q: 300 tractor exhaust and valve cover valve oil. What's going on

- Maybe the liner is broken,Let's see if there is water in the oilI hope my answer will help you.

- Q: Beno Tractor and Ben Tractor which is good

- Lanxi Benye tractor, garbage in the fighter, buy less than a year, use less than a month, it is broken, and the engine is broken, completely nobody, now sued to the court

- Q: What are the tractors on the tractor?

- Enterprises completed and put into operation 50 years, for the national agricultural mechanization to provide more than 3.5 million technical equipment.

- Q: Why does not the tractor belong to the car?

- It is a farm machine, but the car is a class called motor vehicles, cars refer to the transport of goods or passengers engaged in long-distance or short-distance transport, the tractor is engaged in agricultural operations in the agricultural machinery of agricultural machinery, the normal is not allowed to engage in long-distance

- Q: A tractor driver's license will be valid for 6 years in November of 20l0

- (2) tractor driving license; (3) certificate of physical condition issued by medical institutions at or above the county level or at the army level.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls ASTM A562

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3434 unit

- Supply Capability:

- 45343 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords