Pre-painted Galvanized Steel Sheet/ Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications;

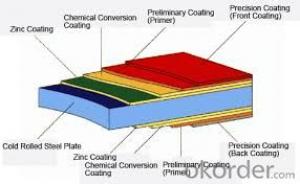

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Second Glance of Photo

Galvanzied steel coil( GI, CRC)

Color coated steel coil(PPGI)

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves unwinding the steel coil, passing it through a set of rotating circular blades called slitters, and then rewinding the resulting narrower strips onto separate spools.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials.

- Q: This problem has puzzled me for a long time i always think about why stranded people on islands cant make a proper civilization and i always think it comes down to the ability to work metal. But its not like they could make a steel smelter/furnace out of sand...they would need an older one to use to make the new one...where the hell did the first one come from then????

- You don't need steel to make a smelter. Early ones were made of simple materials such as stone (though the first ones developed would be to smelt gold, then bronze, then iron-widespread use of steel is a relatively late innovation) A desert island resident however would be unlikely to have the skills, nor the iron ore to make one.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, providing strength and durability. The coils are first shaped into the desired boiler structure, such as the shell and tubes, and then welded together to create a sturdy and leak-proof vessel. Additionally, the coils are often used to manufacture the heat exchangers and other critical parts of the boiler, ensuring efficient heat transfer and reliable operation.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- The difference in stainless steel cookware is the amount of different metals used when making them. 18-10 is the best combination. I have Tramontina SS pots and pans and love them. Nice heavy bottoms that evenly heat. Getting used to cooking with stainless is a bit difficult. You need to start with high heat and then turn it down when you add ingredients. This assists in food not sticking.

- Q: How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components by being processed into various shapes and sizes, such as beams, columns, and plates. The coils are unwound and then cut, bent, or shaped to meet the specific requirements of the construction project. Additionally, the high strength and durability of steel make it a preferred material for construction, ensuring the components can withstand heavy loads and harsh environmental conditions.

- Q: How are steel coils used in the manufacturing of storage racks?

- Steel coils are used in the manufacturing of storage racks by being cut into smaller, more manageable pieces that are then shaped and welded into the desired rack structure. The strength and durability of the steel coils make them an ideal material for supporting heavy loads and ensuring the stability of the storage racks.

- Q: Please explain why steel is denser than wood.

- Steel is made up mostly of iron with a very small amount of carbon added. Iron is a metallic element with a high atomic number which means it's molecules contain lots of particles and consequently it is relatively heavy, or dense. Wood on the other hand is made up mostly of carbon which is a non-metallic element with a lower atomic number and fewer particles in each molecule, and consequently it is a lot lighter or less dense than steel.

- Q: What are the common surface treatments for galvanized steel coils?

- Galvanized steel coils can undergo various surface treatments to improve their corrosion resistance and appearance. Passivation is one such treatment, where a protective material like zinc phosphate or chromate is applied to create a barrier against moisture and atmospheric elements. This also enhances the adhesion of subsequent coatings or paints. Another treatment is chromate coating, which involves applying a thin layer of chromate to the steel surface. This provides extra protection against corrosion and enhances the steel's appearance. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is a common treatment that involves applying a thin layer of oil to prevent rust and corrosion during storage and transportation. It also offers temporary protection against moisture and other environmental factors until the steel is further processed or used. These surface treatments are widely used to improve the performance, durability, and appearance of galvanized steel coils, ensuring they can withstand harsh conditions and maintain their quality over time.

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Pre-painted Galvanized Steel Sheet/ Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords