Pre-Painted Coated Galvanized Steel Coils/PPGI/Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications;

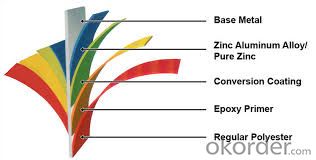

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Second Glance of Photo

Galvanzied steel coil( GI, CRC)

Color coated steel coil(PPGI)

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q:How are steel coils transported?

- Steel coils are typically transported by truck, train, or ship, depending on the distance and location. They are usually secured with steel strapping or wire rope and loaded onto specialized trailers or containers designed to handle their weight and size.

- Q:What are the common methods of forming steel coils?

- There are several common methods for forming steel coils, each with its own unique advantages and applications. The most common method is known as hot rolling. This involves heating a large steel slab to a high temperature and passing it through a series of rollers to reduce its thickness. The steel is then coiled into a large, continuous roll. Hot rolling is typically used for producing steel coils with a consistent thickness and a smooth surface finish. It is commonly used in industries such as automotive, construction, and manufacturing. Another method is cold rolling, which is similar to hot rolling but is performed at room temperature. Cold rolling involves passing the steel through a set of rollers to further reduce its thickness and improve its surface finish. This process is often used to produce steel coils with precise dimensions and excellent mechanical properties. Cold-rolled steel coils are commonly used in applications that require high strength, such as in the production of appliances, electrical components, and structural components. A third method is known as galvanizing. This involves coating the steel coil with a layer of zinc to protect it from corrosion. The steel coil is first cleaned and then immersed in a bath of molten zinc. The zinc adheres to the surface of the steel, forming a protective layer. Galvanized steel coils are widely used in outdoor applications, such as roofing, fencing, and automotive parts, due to their excellent corrosion resistance. Lastly, there is the electro-galvanizing method. This process involves applying a thin layer of zinc to the surface of the steel coil through an electroplating process. The steel coil is immersed in an electrolyte solution and an electric current is passed through it, causing the zinc to deposit onto the surface of the steel. Electro-galvanized steel coils are commonly used in industries that require a smooth and aesthetically pleasing finish, such as in the production of appliances, automotive parts, and decorative items. Overall, these common methods of forming steel coils provide a wide range of options for different applications and requirements. Whether it is hot rolling, cold rolling, galvanizing, or electro-galvanizing, each method offers unique benefits in terms of strength, durability, surface finish, and corrosion resistance.

- Q:How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed through a series of steps. The coils are first uncoiled and then straightened before being cut to the desired length. These cut lengths are then shaped and bent into the required reinforcement bar shape using specialized machinery. Finally, the bars are heat-treated and cooled to enhance their strength and durability. Overall, steel coils serve as the primary raw material for the production of construction reinforcement bars, providing the necessary strength and structural integrity to concrete structures.

- Q:what is tool steel and does it function better than carbon or spring steel?

- NO. Tool steel is very hard and brittle. Carbon spring steel is better but rusts. Stainless steel is weather resistant. A mix like those for knives are good. For the ultimate, do the japanese way of folding it hundreds of times, then, use three different types of steel. For the center and the back a softer and flexible steel, for the edge hard to keep its edge, and an outer layer to take some weathering.

- Q:How are steel coils used in the production of lighting fixtures?

- Steel coils are an essential component in the production of lighting fixtures. These coils are typically made of high-quality steel, which provides durability and strength to the final product. In the manufacturing process, the steel coils are first uncoiled and then passed through a series of machines. These machines cut and shape the steel into various parts and components required for lighting fixtures. The steel is often bent, stamped, or rolled to create the desired shapes and sizes. These parts may include the base, frame, arms, or other structural elements of the lighting fixture. Once the steel components are formed, they are then further processed and finished. This may involve welding, polishing, or coating the steel to enhance its appearance and protect it from corrosion. After the steel parts are finalized, they are assembled with other components like electrical wiring, bulbs, shades, and switches to create the complete lighting fixture. The use of steel coils in lighting fixture production ensures that the finished products are sturdy, long-lasting, and able to withstand various environmental conditions. Steel's strength allows for the creation of intricate designs and shapes, enabling manufacturers to produce lighting fixtures that are not only functional but also aesthetically pleasing. Overall, steel coils play a crucial role in the production of lighting fixtures by providing the necessary strength, durability, and versatility required for these products.

- Q:What are the safety considerations when handling steel coils?

- When handling steel coils, there are several safety considerations that should be taken into account. Firstly, it is essential to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. This protective gear helps to minimize the risk of injuries from sharp edges, flying debris, or accidental contact with the coils. Secondly, it is important to have a clear understanding of the weight and dimensions of the steel coils being handled. Steel coils can be extremely heavy, and improper lifting techniques can result in back strains, muscle pulls, or even more severe injuries. Therefore, it is crucial to use proper lifting techniques, such as bending the knees and keeping the back straight, or utilizing lifting equipment like cranes or forklifts when necessary. Additionally, steel coils can be unstable and prone to rolling or shifting during handling. To prevent accidents, it is crucial to secure the coils properly before moving or stacking them. This can be done by using appropriate lifting attachments, banding the coils together, or utilizing racks or other storage systems specifically designed for steel coils. Furthermore, it is important to be aware of the potential hazards associated with the steel coils, such as sharp edges, oil or grease coatings, or even damage to the coils themselves. It is essential to inspect the coils for any abnormalities or defects before handling them, as well as ensuring that they are stored in a safe and stable manner to prevent accidents. Lastly, proper communication and training are essential when handling steel coils. It is crucial to establish clear communication channels between workers to ensure that everyone is aware of their roles and responsibilities. Additionally, providing training on safe handling techniques, potential hazards, and emergency procedures can help minimize the risk of accidents and injuries. In conclusion, when handling steel coils, it is important to wear appropriate PPE, use proper lifting techniques, secure the coils properly, be aware of potential hazards, and ensure proper communication and training. By following these safety considerations, the risk of accidents and injuries can be significantly reduced.

- Q:I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- Personally I use stainless steel for my own dogs because ti is easy to keep clean, and doesn't weigh too much when I am carrying 3 large bowls full of food. Plus when I drop them they don't break. The only reason I don't use plastic is because my dogs like to chew anything plastic :P I use plastic for my foster cats and foster puppies and have never had any sort of infection. Personally I think that is some sort of myth as I have never known anyone's pet to get an infection from a plastic bowl. As long as you keep them clean, plastic or stainless are both fine

- Q:What is the average turnaround time for processing steel coils?

- The average turnaround time for processing steel coils can vary depending on several factors such as the size and complexity of the coils, the specific processing requirements, and the efficiency of the manufacturing facility. However, in general, the average turnaround time for processing steel coils can range from a few days to a couple of weeks.

- Q:How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled with great care during transportation to prevent damage. They are usually secured with steel bands or straps to keep them in place and prevent them from shifting or rolling. Additionally, they are often placed on specialized transportation equipment, such as flatbed trailers or coil carriers, that have built-in supports to hold the coils securely. These measures help ensure that the coils remain stable and protected throughout the transportation process, minimizing the risk of damage.

- Q:where can i find information online about steel residential homes that use solar energy?

- Sun energy technologies is not as commonplace as it's photovoltaic cousin, but is nevertheless an important piece in the actual sun power bigger picture. Solar thermal uses solar power in order to heat either drinking water or even atmosphere, that is after that transferred via collectors within order to it's location. With all the actual challenges we're dealing with in respect within order to global warming and also the stunning increase in air pollution caused by green house gas, solar energy as well as also the techniques utilized to funnel it have become vitally important to our long term which of our planet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-Painted Coated Galvanized Steel Coils/PPGI/Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords